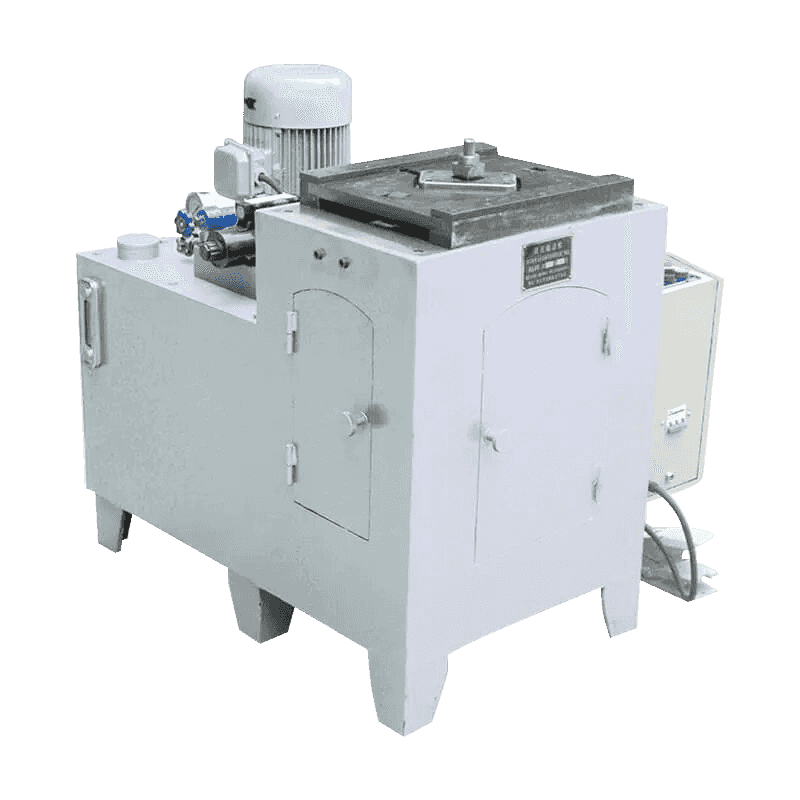

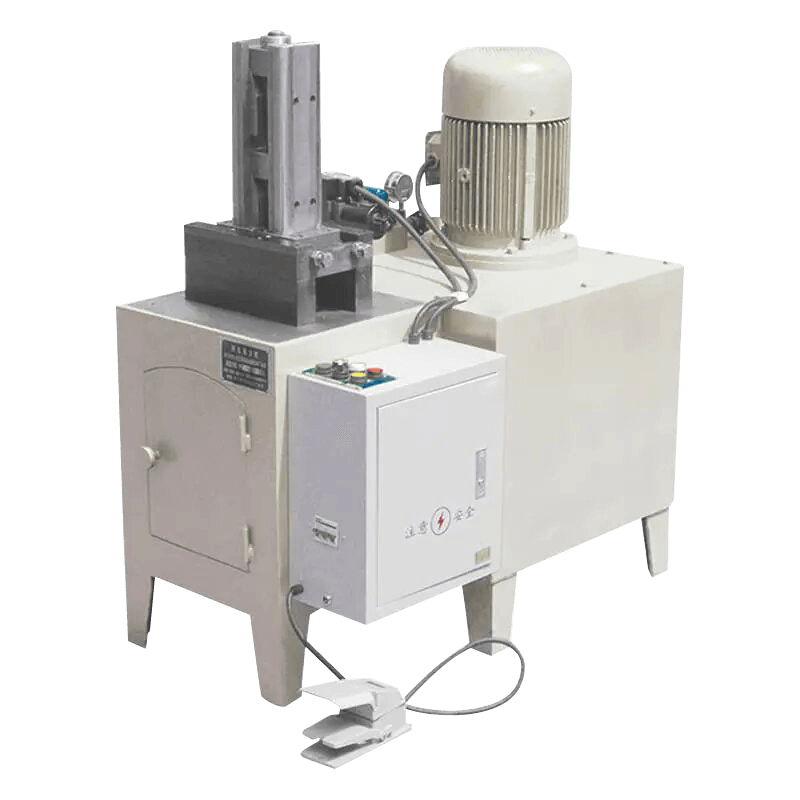

Specification

| Parameter Category | Specification Content | Remarks / Additional Information |

|---|---|---|

| Production Capacity | 1,000–25,000 cans/hour | Depends on can dimensions |

| Can Shape | Square / Rectangular | Food, Chemical, Specialty |

| Material | Tinplate, Steel | Thickness 0.18–0.30 mm |

| Automation Level | Semi-Automatic / Fully Automatic | Includes forming, seaming |

| Control System | PLC + HMI | Full monitoring and error detection |

| Power Requirement | 380V/50Hz | Can be customized |

| Tooling Options | Interchangeable dies | Supports multiple sizes |

| Machine Footprint | 12–40 m² | Line layout dependent |

| Quality Compliance | ISO9001, CE | International standard |

| Optional Features | Printing, Labeling | For branding purposes |

| Maintenance | Preventive maintenance schedule | Ensures long-term operation |

| Safety Features | Emergency stop, overload protection | CE certified |

| Application | Food, Beverage, Chemical | Supports diverse industries |

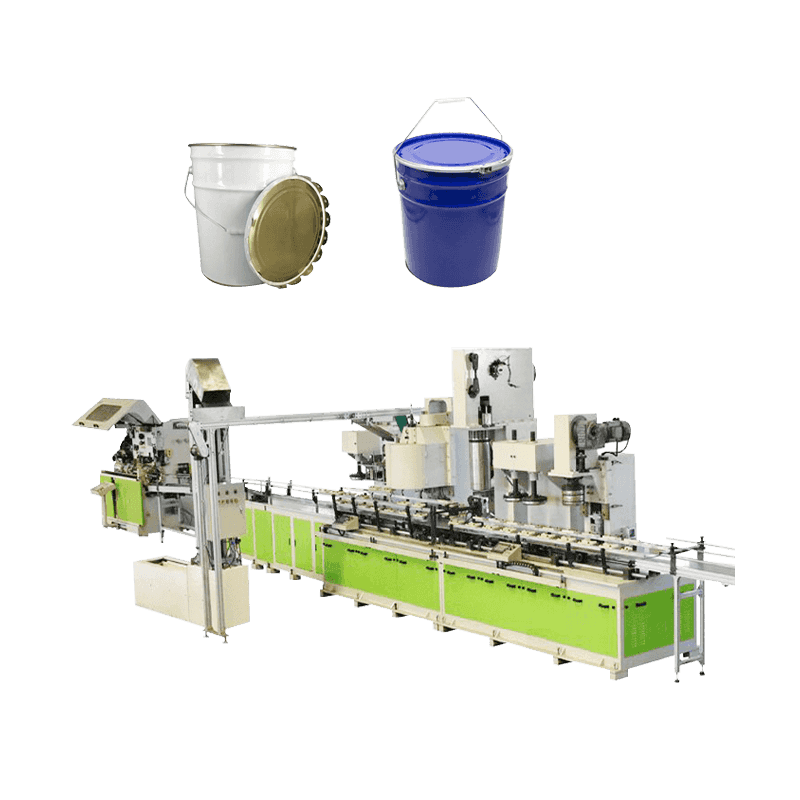

Application

Confectionery Packaging

Used to produce square or rectangular tin cans for chocolates, cookies, and candies, optimizing shelf display and stacking efficiency.

Specialty Food Packaging

Suitable for nuts, biscuits, and tea products, providing a unique shape for retail differentiation and premium presentation.

Industrial Use

Can be applied to chemicals and paints that require square-shaped tin packaging for efficient storage and transport.

Advantage

Space-Saving Design

Produces square or rectangular cans that optimize storage and transportation efficiency.

Attractive Packaging

Supports premium product presentation and shelf differentiation for cookies, tea, or confectioneries.

Durable Construction

Ensures strong and leak-proof packaging, protecting contents during handling and shipping.

English

English عربى

عربى русский

русский