Specification

| Parameter Category | Specification Content | Remarks / Additional Information |

|---|---|---|

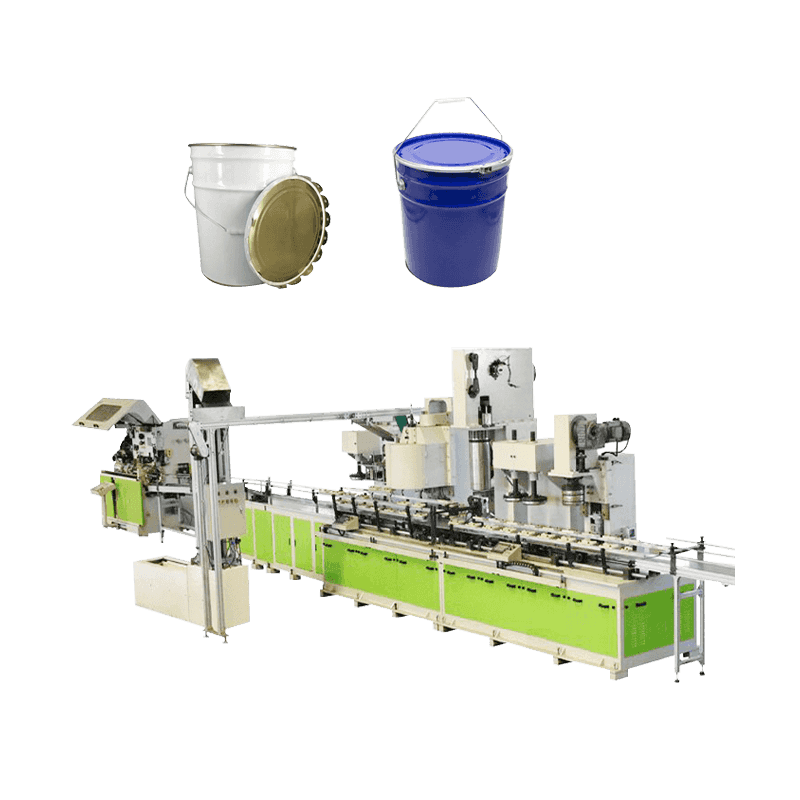

| Production Capacity | 1,000–30,000 cans/hour | Depends on can size, material, and automation level |

| Can Types | Food, Beverage, Chemical, Industrial | Supports both 2-piece and 3-piece cans |

| Material Compatibility | Tinplate, Aluminum, Steel | Custom tooling required for different thicknesses |

| Automation Level | Manual to Fully Automatic | PLC and servo control options available |

| Control System | PLC with HMI interface | Real-time monitoring and alarms included |

| Power Requirement | 380V/50Hz or 220V/60Hz | Can be customized per client country |

| Machine Footprint | 10–50 m² | Depends on production line configuration |

| Tooling Options | Interchangeable dies for multiple can sizes | Quick-change system reduces downtime |

| Quality Compliance | ISO9001, CE, CB | Ensures international quality standards |

Application

Food Packaging

Used for producing cans for various food products, including canned vegetables, fruits, seafood, and ready-to-eat meals, ensuring safe storage and long shelf life.

Industrial Chemicals

Suitable for manufacturing metal cans to store chemicals such as paints, solvents, adhesives, and lubricants, providing airtight and corrosion-resistant packaging.

Consumer Goods

Applicable for beverage cans, aerosol products, and household items, enabling high-volume production with consistent quality and durability.

Advantage

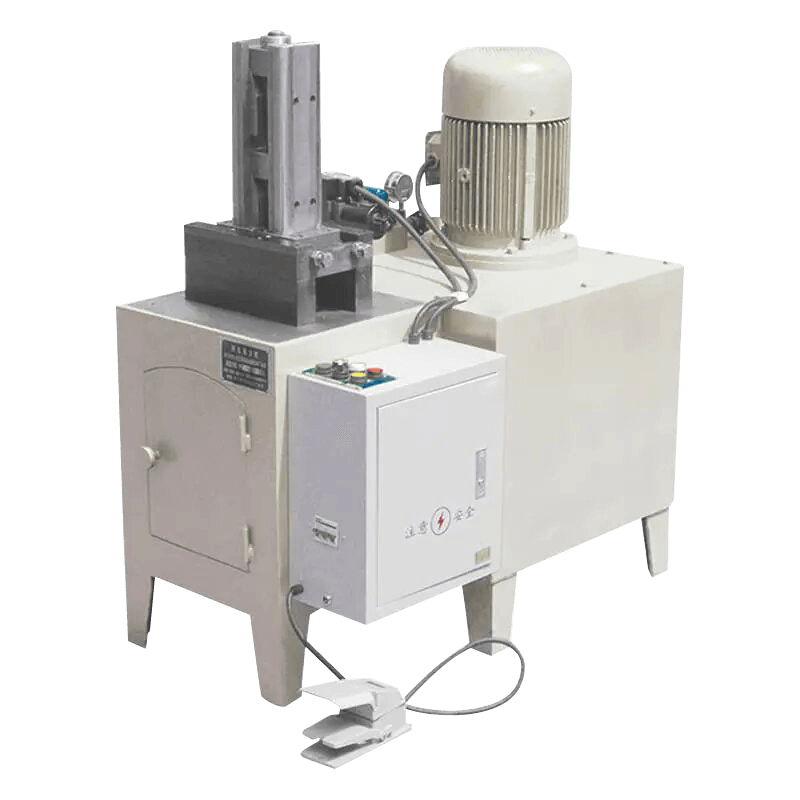

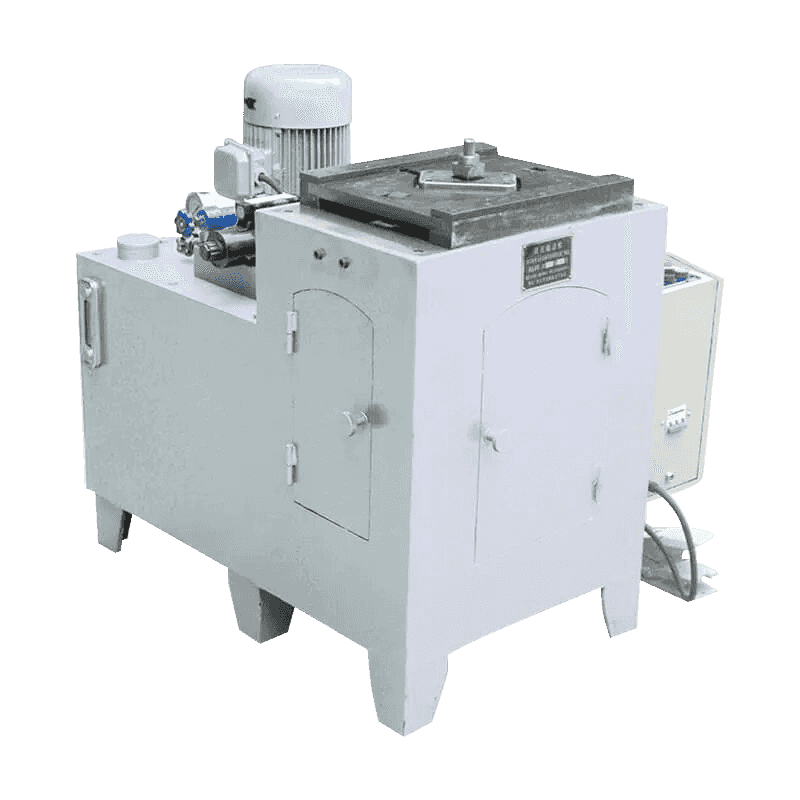

High Efficiency

Designed for continuous can production, enabling high-speed output and reducing manual labor requirements, increasing overall manufacturing efficiency.

Versatility

Capable of producing cans of various shapes, sizes, and materials, suitable for food, beverage, and industrial applications.

Consistent Quality

Ensures uniform can dimensions, precise sealing, and excellent surface finish, reducing defects and improving product reliability.

English

English عربى

عربى русский

русский