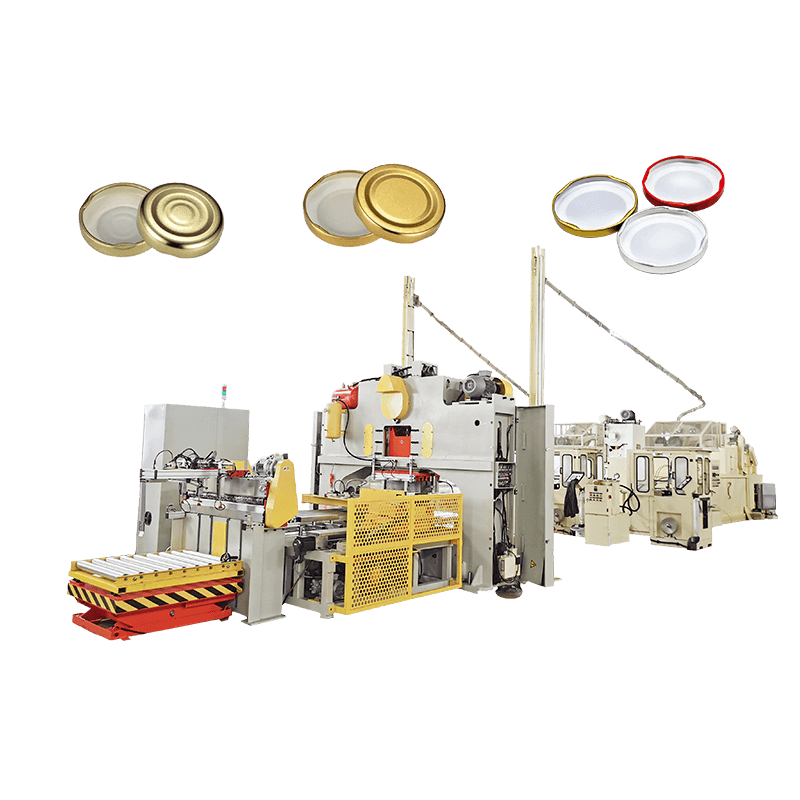

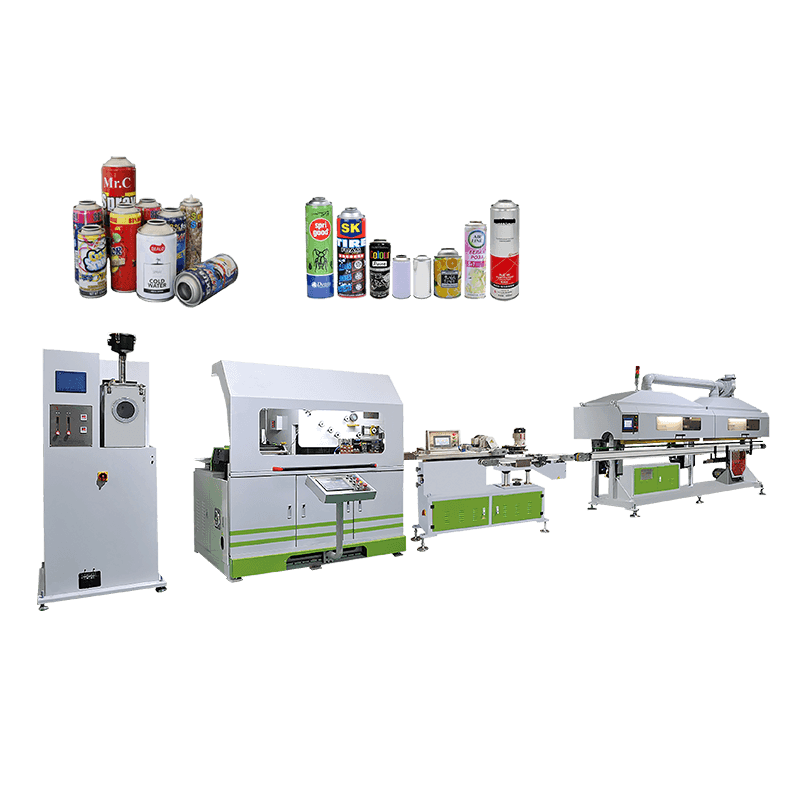

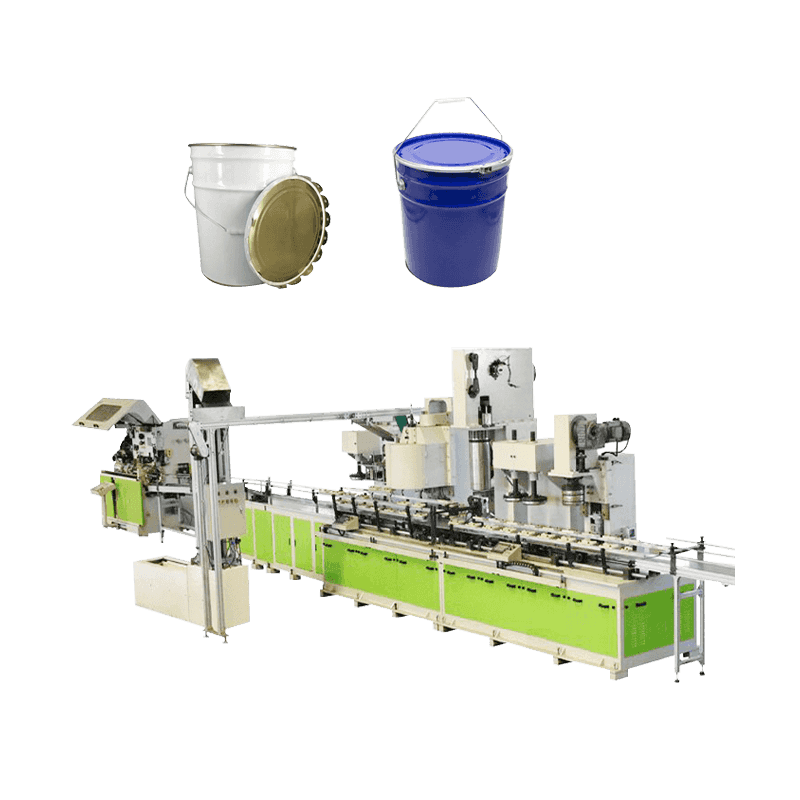

The commonly used cans are three-piece sanitary cans which consist of a body and two end pieces that are joined together to provide a hermetic, seal. Commonly used for foods that are heat-processed they are also used for packaging powders, syrups, and many other products that are not heat-processed. The common shape is a round cylinder but square and oval flat cans are used, particularly for seafood processing.

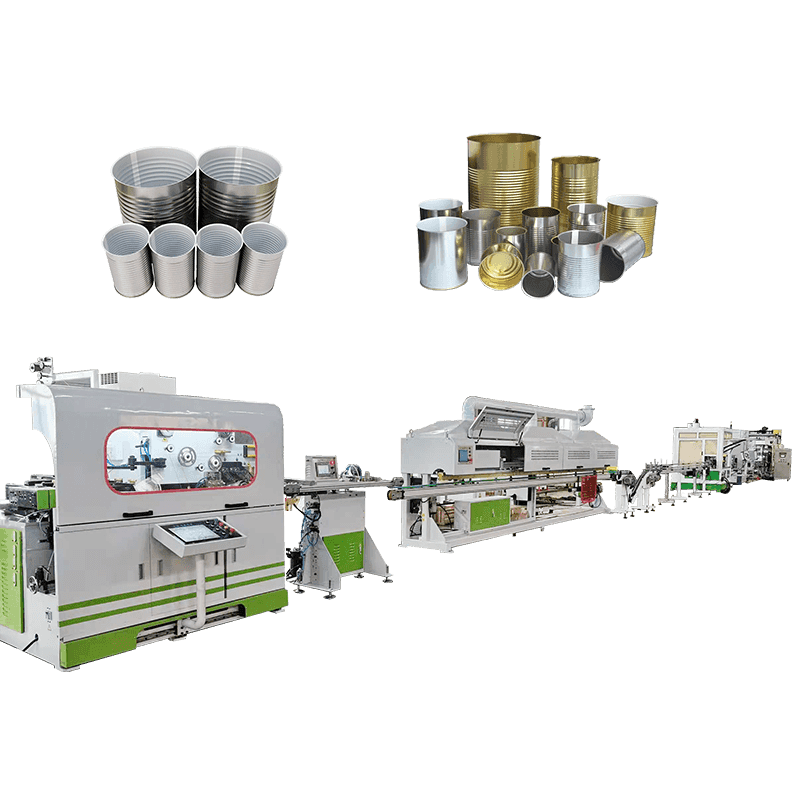

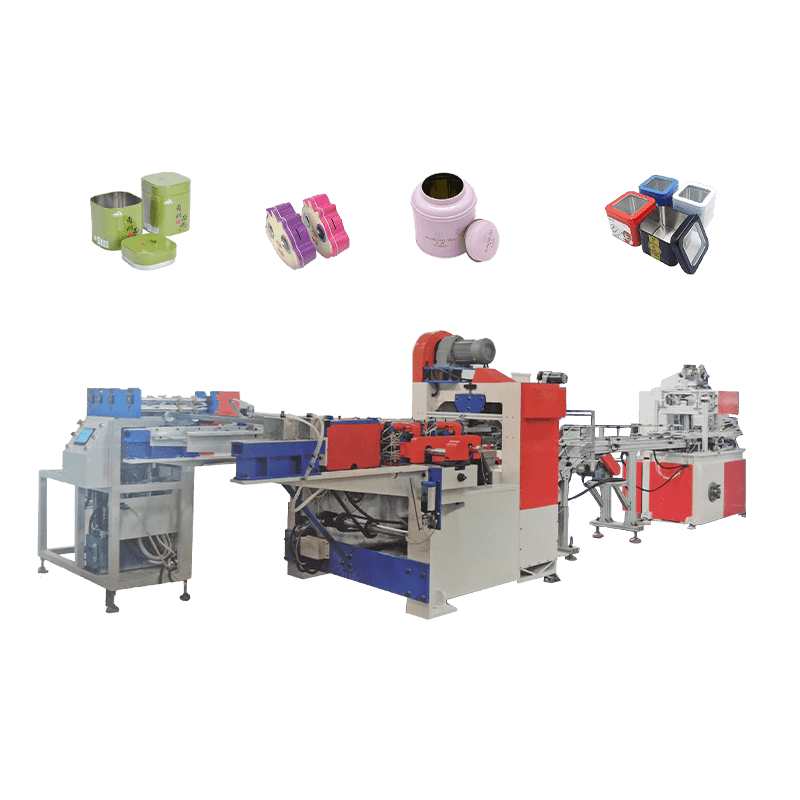

3 Piece Food Tin Can Production Line

Product Description

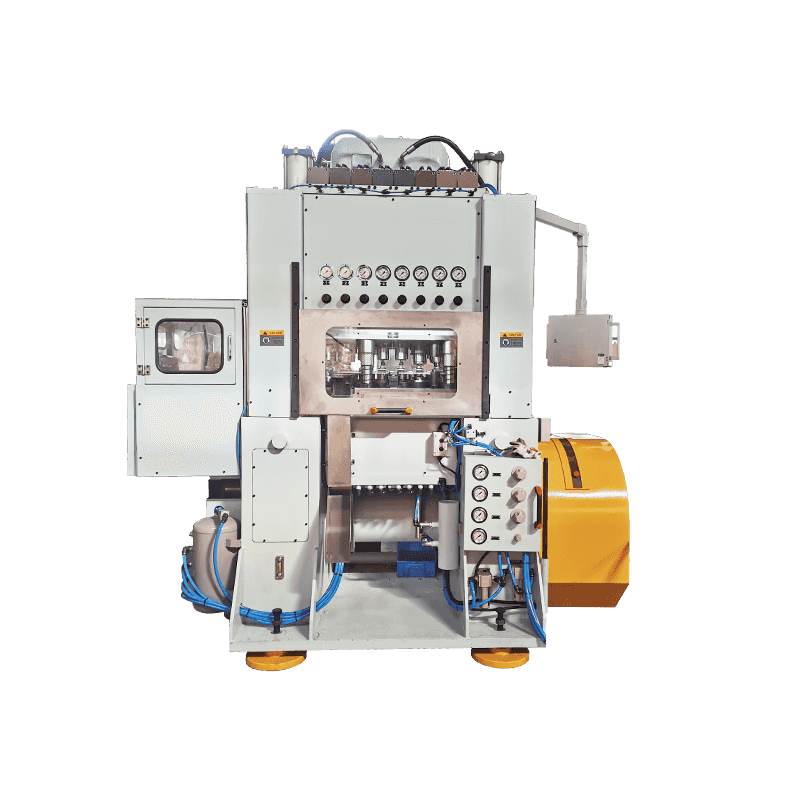

|

GT3B50-NF |

Necking+Flanging |

Tooling Numbers |

Capacity (ppm) |

Tin Can Diameter (mm) |

|

Necking+Flanging+Beading |

6-8 |

150-500 |

D52-99 |

|

|

GT3B50-NFS |

Necking +Flanging+Seaming |

6-8 |

150-500 |

D52-99 |

|

Flanging+Beading+Seaming |

6-8 |

150-500 |

D52-99 |

|

|

GT3B90-FBS |

Flanging+Beading+Seaming |

4 |

150-500 |

D99-153 |

-

Introduction to 2-Piece DRD Can Production Line The 2-piece DRD (Drawn and Redrawn) can production line is a manufacturing process used to produce aluminum cans, commonly used for beverages and other ...

READ MORE -

If you’ve been following packaging trends lately, you’ve probably noticed one thing: twist-off lug caps are everywhere. From beverages and sauces to oils and even cosmetics, these caps are a “quiet he...

READ MORE -

Introduction to Twist-Off Lug Cap Production Lines Twist-off lug cap production lines are specialized systems designed for high-speed manufacturing of metal caps used in beverage and food packaging. T...

READ MORE

1. What is the process flow of the 3 Piece food tin can production line?

The 3 Piece food tin can production line is an efficient and precise industrial production equipment specially used for manufacturing various types of food packaging cans. This production line usually includes the following key process steps:

a. Material preparation and cutting: The raw materials (usually food-grade tin plates or steel plates coated with anti-rust coating) are sent to the production line after inspection and acceptance. At this stage, the materials are cut into plates that meet the specific can size.

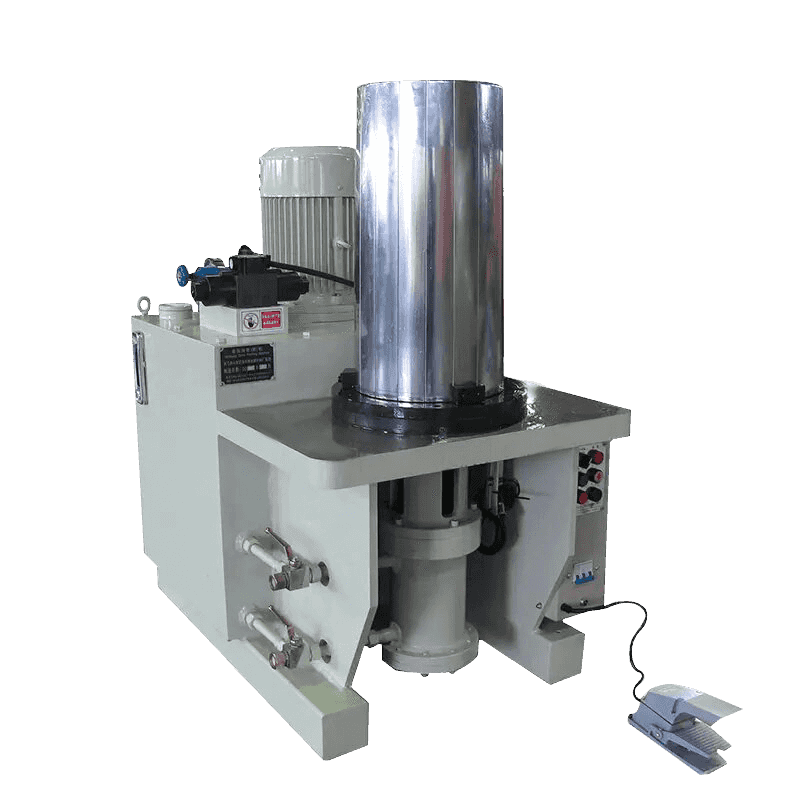

b. Forming and molding: The cut plates are fed into the molding machine, and the flat plates are transformed into the main shape of the can through bending and stamping processes. This step requires high-precision machines and molds to ensure the consistency of size and shape of each can.

c. Welding and sealing: The formed can body needs to be welded, usually using gas shielded welding or resistance welding technology to permanently seal the side walls and bottom of the can body to ensure the sealing and structural strength of the can body.

d. Stamping and shaping: After welding, the can body is stamped and shaped to remove excess edges and corners, so that the surface of the can body is flat, burr-free, and achieves the appearance required by the final design.

e. Internal and external painting and decoration: After the surface of the can body is cleaned and surface treated, it is painted or printed inside and outside. The inner coating protects the food from metal contamination, and the outer coating or printing increases the visual appeal and brand identity of the can body.

f. Inspection and packaging: The last step of the production line is to conduct strict quality inspection on the finished can body to ensure that each can body meets the standard requirements. Any defective products are excluded through automated testing equipment and manual sampling. Qualified can bodies can be shipped to the market after packaging.

The 3 Piece food tin can production line ensures the dual guarantee of production efficiency and product quality through the above precise process flow, meeting the strict requirements of the food industry for safety, hygiene and aesthetics.

2. What is the design and customization capability of 3 Piece food tin cans?

As one of the important forms of food packaging, 3 Piece food tin cans have a wide range of design and customization capabilities to meet the needs of different customers and markets. The following are the features of this production line in terms of design and customization:

a. Diverse size and shape options: The production line is able to produce cans of different sizes and shapes according to customer needs, from small single-serving cans to large family cans, as well as special shapes such as heart-shaped or polygonal cans.

b. Highly customizable printing and decoration options: 3 Piece food tin cans can print the customer's brand logo, product information or visual patterns that attract consumers directly on the surface of the can through high-definition printing technology. This customized printing not only enhances the market competitiveness of the product, but also enhances the brand's recognizability.

c. Innovative functional design: In addition to traditional round and square cans, the production line is also able to design and manufacture cans with innovative functions, such as cans with easy-open lids, sealing lids or special nozzles to meet the packaging needs of specific foods.

d. Environmental protection and sustainable design: The production line takes environmental factors into consideration when designing the tank body, promotes the use of recyclable materials and environmentally friendly coatings, reduces the impact on the environment, and meets the modern consumers' preference for sustainable development.

3. What are the applications and development trends of 3 Piece food tin can production lines in the market?

As an important equipment in the food packaging industry, the application and development trends of 3 Piece food tin can production lines are affected by many factors, including technological progress, changes in market demand and stricter environmental regulations.

a. Wide application in the market:

3 Piece food tin cans are widely used in the packaging of various types of food, including canned fruits and vegetables, meat products, seafood, nuts and snacks, etc. Its excellent sealing and antioxidant properties ensure that food remains fresh and safe for a long time, and are favored by food production companies.

b. Technology and equipment replacement:

With the advancement of science and technology and the intensification of market competition, 3 Piece food tin can production lines are constantly updated. Introducing more advanced automation technology, intelligent control systems and environmental protection equipment to improve production efficiency and product quality, reduce production costs and enhance market competitiveness.

c. Innovative materials and environmental protection trends:

In terms of material selection, production lines tend to use lighter and more environmentally friendly materials, such as lightweight steel plates and recyclable materials. At the same time, promoting the use of environmentally friendly coatings and clean production technologies, reducing resource consumption and carbon footprint, and meeting the society's requirements for environmentally friendly and sustainable development.

d. Development of regional markets:

3 Piece food tin can production lines show a diversified development trend in the global market. Especially in markets with rapid economic growth and stable food consumption growth, its demand continues to increase. At the same time, under the trend of international trade and market globalization, the export market of production lines is also expanding, bringing broader development space for enterprises.

English

English عربى

عربى русский

русский