2 piece DRD cans are widely used in the field of food packaging.

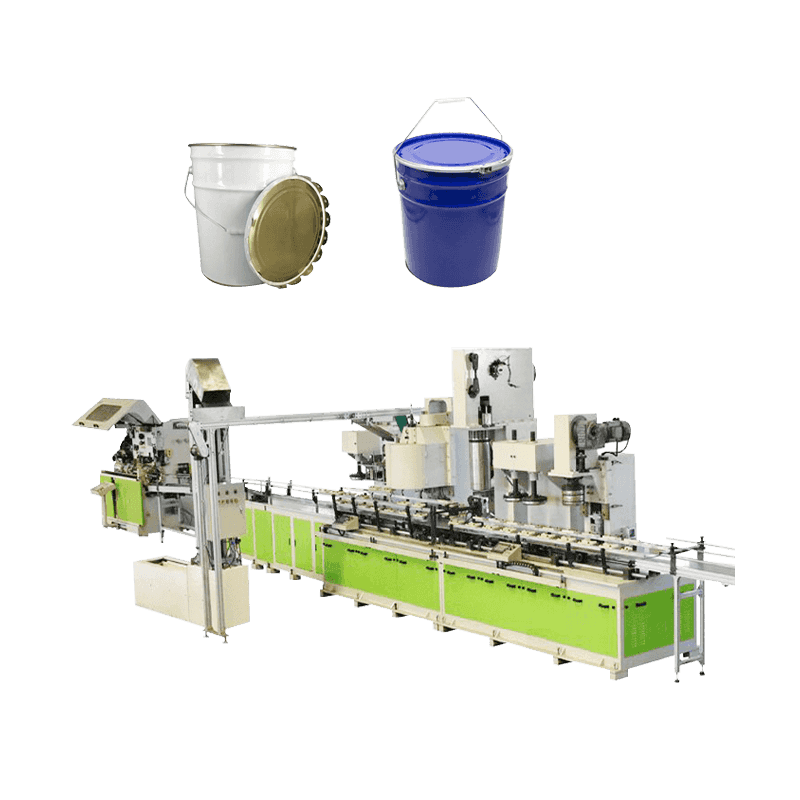

2 Piece DRD Can Production line

Product Description

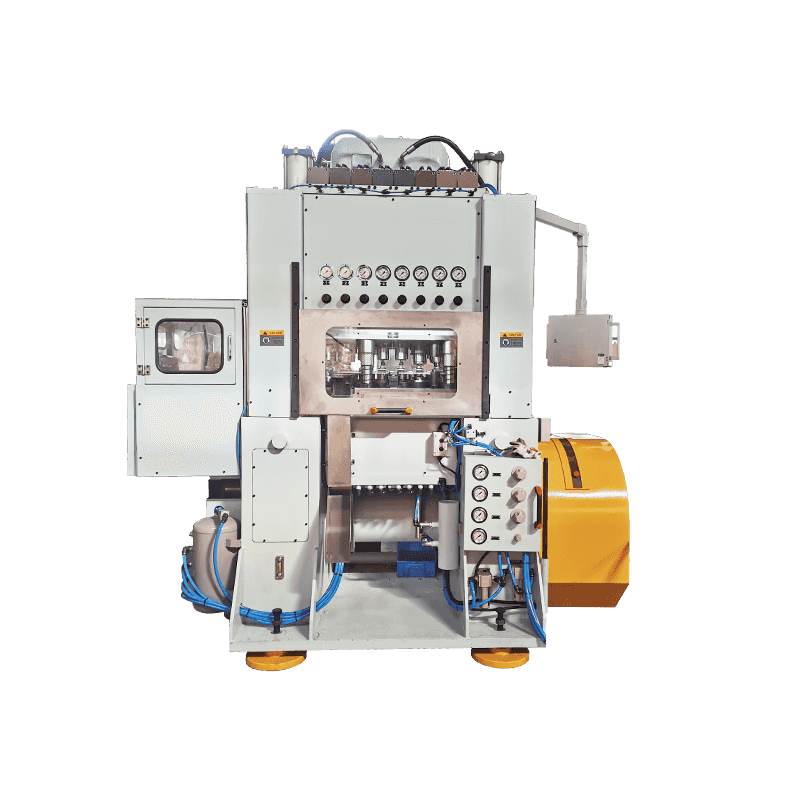

|

Model |

Slide stroke(mm) |

Nominal Pressure (kN) |

SPM |

Number of dies |

|

GT2A-80B |

170 |

800 |

85-100 |

1-2 |

|

170 |

1000 |

85-100 |

2-3 |

|

|

GT2A-110B |

170 |

1100 |

85-100 |

3-4 |

|

GT2A-140B |

170 |

1400 |

85-100 |

4-5 |

-

Introduction to 2-Piece DRD Can Production Line The 2-piece DRD (Drawn and Redrawn) can production line is a manufacturing process used to produce aluminum cans, commonly used for beverages and other ...

READ MORE -

If you’ve been following packaging trends lately, you’ve probably noticed one thing: twist-off lug caps are everywhere. From beverages and sauces to oils and even cosmetics, these caps are a “quiet he...

READ MORE -

Introduction to Twist-Off Lug Cap Production Lines Twist-off lug cap production lines are specialized systems designed for high-speed manufacturing of metal caps used in beverage and food packaging. T...

READ MORE

Typical Application Areas of 2 Piece DRD Cans

Overview of 2 Piece DRD Can Technology in Modern Metal Packaging

Two-piece Draw and Redraw (DRD) cans are widely recognized in the metal packaging industry for their seamless construction, stable wall thickness, and suitability for high-speed automated production environments. Zhoushan Sinda Machinery Co., Ltd., located in Zhoushan—China’s leading production base for metal packaging machinery—provides advanced 2-piece DRD Can Lines that support consistent forming, redrawing, trimming, and coating processes. The DRD structure, being formed from a single metal sheet, reduces leakage points and improves resistance to internal and external forces. As a result, these cans meet the requirements of many industries, especially where durability, hygienic conditions, visual uniformity, and compatibility with automatic filling systems are important.

Applications in the Food and Beverage Industry

The food sector is one of the primary users of 2-piece DRD cans because the seamless body structure supports retort sterilization, pressure variations, and long-term product storage. Products like canned meats, fish, dairy-based items, coffee, and ready-to-eat meals benefit from the DRD forming method because it reduces the risk of deformation during heating or cooling cycles. In addition, the smooth interior surface supports hygienic filling and helps maintain product consistency. With production support from the 2-piece DRD Can Lines of Zhoushan Sinda Machinery Co., Ltd., food manufacturers can achieve consistent can dimensions suitable for high-speed filling, seaming, and packaging lines.

Food Industry Applications of DRD Cans

| Food Category | Reason for Using DRD Cans |

|---|---|

| Canned Meat | Stable wall structure supports thermal processing. |

| Fish and Seafood (Tuna, Sardines) | High impact resistance suitable for global transportation. |

| Ready Meals | Uniform shape aids in effective heat transfer during sterilization. |

| Condensed Milk and Dairy Products | Compatible with rapid filling and sealing procedures. |

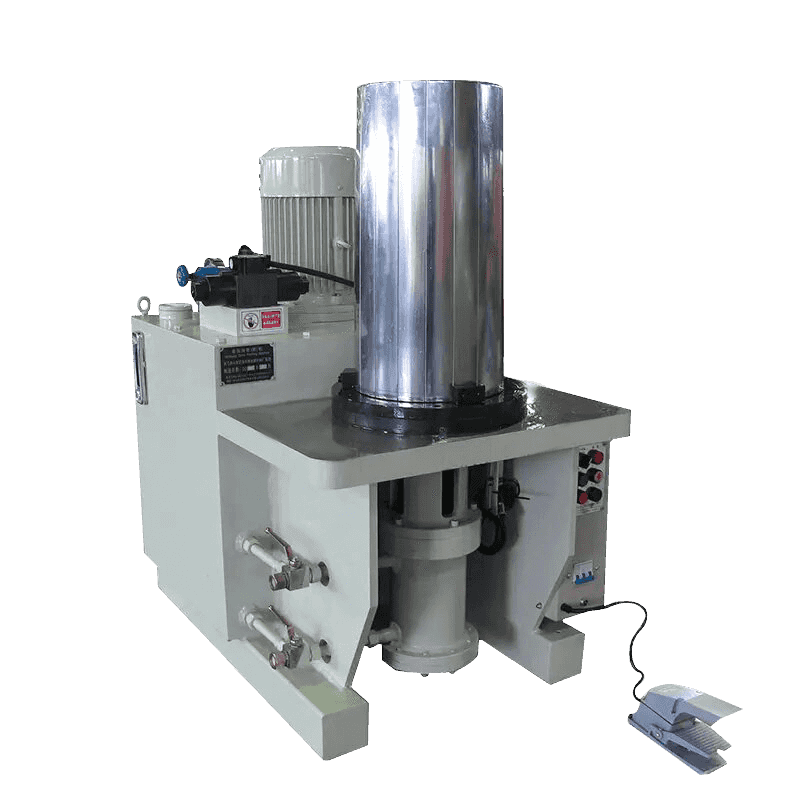

Use in the Chemical and Industrial Products Sector

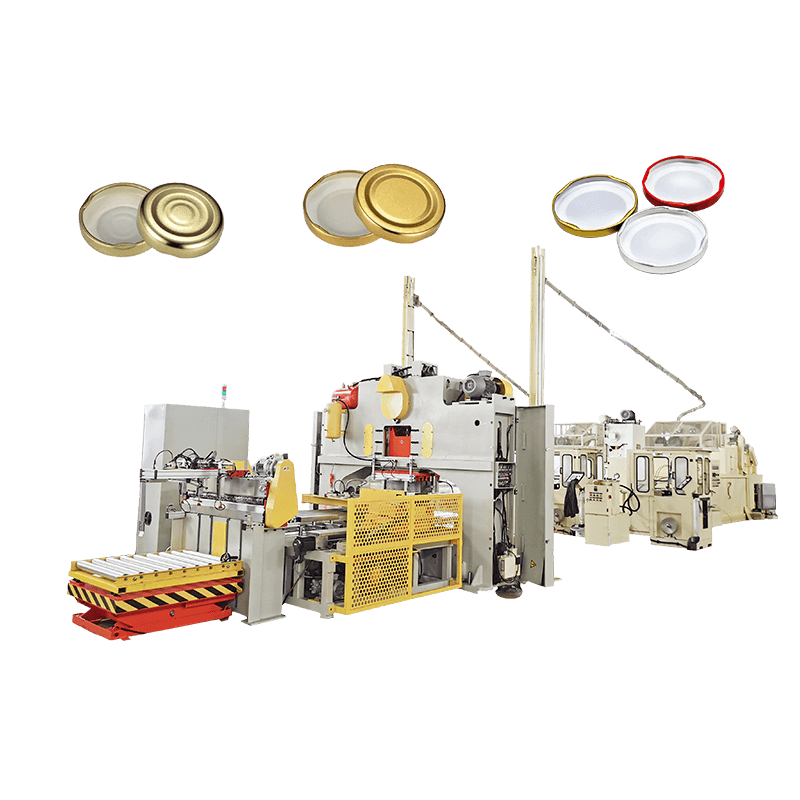

Chemical products often require packaging that can withstand pressure variations, resistance to corrosive substances, and long-distance transport conditions. DRD cans are frequently chosen for adhesives, solvents, automotive additives, and household chemicals due to their continuous-wall structure, which lowers the chance of leakage while providing consistent dimensional accuracy. Zhoushan Sinda Machinery Co., Ltd., through its Chemical Tin Can Lines and Metal Lids & Bottom Production Line, supports manufacturers in producing cans with suitable internal coatings and stable exterior forms. These cans are compatible with modern sealing technologies and can safely contain a range of chemical formulations.

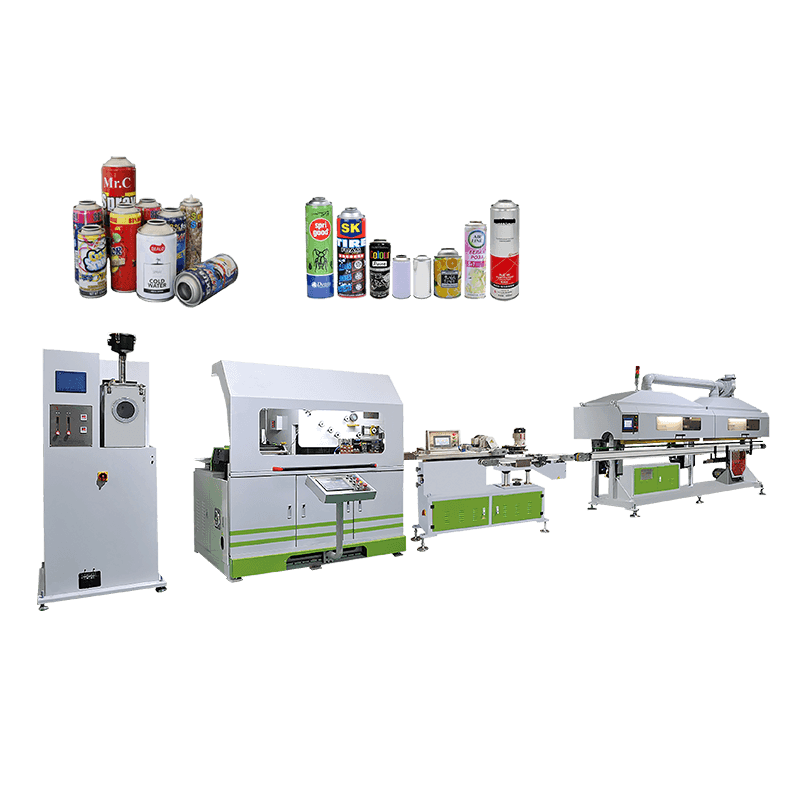

Applications in the Aerosol Industry

The aerosol market depends on containers that can withstand internal gas pressure without deformation or rupture. DRD cans, with their seamless bodies and strengthened bases, meet these demands effectively. They are used for personal care sprays, air fresheners, household products, industrial lubricants, and cooking sprays. Zhoushan Sinda Machinery Co., Ltd.’s Aerosol Dome & Cone Line integrates efficiently with DRD can bodies to produce complete aerosol packaging systems. Dimensional stability is especially important for valve crimping, and the DRD method provides uniformity during high-volume production.

Aerosol Industry Applications of DRD Cans

| Aerosol Product | Packaging Requirement |

|---|---|

| Deodorants and Perfumed Sprays | Requires strong pressure resistance and consistent can shape. |

| Cooking Spray and Oil Spray | Needs hygienic inner walls and reliable aerosol compatibility. |

| Industrial Lubricants | Demands durable can structure under varying temperatures. |

Personal Care and Specialty Packaging Applications

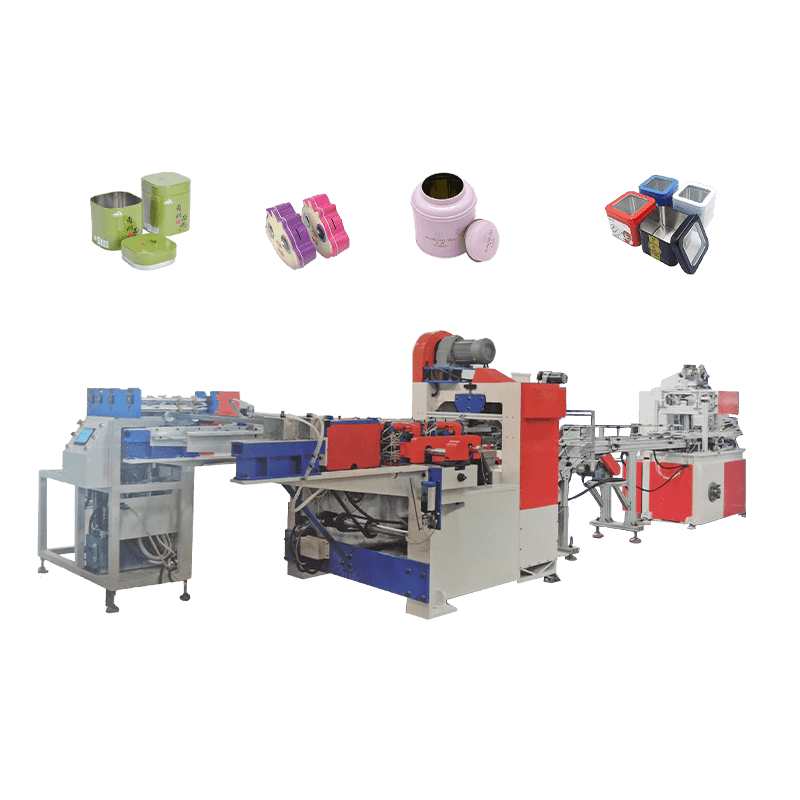

Beyond food, chemical, and aerosol products, DRD cans have a growing presence in the personal care, cosmetic, and specialty packaging markets. The smooth contours and seamless appearance of DRD cans enhance product aesthetics, making them suitable for creams, balms, powders, and promotional items. The stable structure also supports decorative printing, embossing, and custom design features needed for premium packaging. Zhoushan Sinda Machinery Co., Ltd. supports these specialty applications through its Fancy Tin Can Line, where flexibility in design and shaping is essential for meeting branding requirements.

Applications in Gift and Premium Packaging Markets

In the gift packaging sector, DRD cans are frequently used because of their structural stability and attractive appearance. Items such as seasonal gift sets, high-end confectionery, tea, and collectible products benefit from the lightweight but consistent structure of DRD cans. Their ability to maintain shape while supporting elaborate designs makes them suitable for premium branding strategies. The equipment from Zhoushan Sinda Machinery Co., Ltd. allows manufacturers to integrate forming, redrawing, decorative processing, and lid production to create aesthetically functional packaging solutions.

Integration with Modern Can-Making Lines for Expanded Industrial Applications

DRD cans are widely used across sectors that require high-volume, stable, and hygienic packaging. The integration of 2-piece DRD Can Lines with Easy Open-End (EOE) Production Lines, Duplex Slitter lines, Food Tin Can lines, Chemical Tin Can Lines, and Metal Lids & Bottom Production Lines enhances their usability across a broad range of products. Zhoushan Sinda Machinery Co., Ltd. provides complete machinery solutions that streamline forming, trimming, cleaning, coating, and sealing processes, enabling manufacturers to meet diverse industrial needs while maintaining efficiency and consistency. As industries continue to adopt metal packaging for durability and recyclability, DRD cans remain valuable for their ability to combine structural integrity with production flexibility.

Advantages of 2 Piece DRD Cans in the Packaging and Transportation Process

Structural Stability Resulting from Seamless Forming

Two-piece Draw and Redraw (DRD) cans are produced from a single piece of metal sheet, allowing the body to be formed without a side seam. This seamless structure provides consistent strength throughout the container and reduces potential weak points that might occur in multi-piece cans. Zhoushan Sinda Machinery Co., Ltd., located in Zhoushan—the major manufacturing hub for metal packaging machinery in China—develops advanced 2-piece DRD Can Lines that enhance the stability of the formed cans. The consistent wall thickness and integrated base improve the can’s ability to handle internal pressure, vibration, and stacking loads during packaging and transportation. Because the material distribution is controlled precisely during the draw and redraw stages, manufacturers obtain cans suited for demanding supply chains.

Improved Leakage Prevention During Storage and Transit

One of the critical advantages of the 2-piece DRD structure is the reduction of areas that could potentially lead to leaks. In traditional three-piece cans, the side seam may require additional sealing, whereas DRD cans eliminate this concern by forming the container body from a single piece. This characteristic is especially important for products that undergo sterilization, filling under pressure, or long-distance transportation. Zhoushan Sinda Machinery Co., Ltd. integrates high-precision trimming, coating, and cleaning operations into its DRD production lines, ensuring that the inner surface remains suitable for food, chemical, and aerosol applications. With fewer structural connections, the finished cans maintain product integrity more consistently throughout storage and shipment.

Resistance to Deformation Under Mechanical Stress

In both packaging facilities and transportation environments, metal containers are frequently exposed to impact forces, vibrations, and stacking loads. The single-piece structure and uniform wall thickness of DRD cans offer improved resistance to deformation, which helps maintain shape during filling, labeling, palletizing, and transport. This is particularly important for automated systems where stable dimensions support smooth performance on conveyors and filling lines. The advanced forming systems developed by Zhoushan Sinda Machinery Co., Ltd. help achieve dimensional accuracy during the draw and redraw stages. As a result, DRD cans remain compatible with high-speed application requirements and maintain structural integrity during transit.

Key Structural Advantages of 2 Piece DRD Cans

| Advantage | Description |

|---|---|

| Seamless Body | Eliminates side seam weaknesses and lowers risk of leakage. |

| Uniform Wall Thickness | Provides consistent resistance to internal and external pressure. |

| Integrated Base | Enhances load-bearing stability for stacking and transport. |

Compatibility with High-Speed Automated Production Lines

The dimensional consistency of DRD cans also contributes to their suitability for automated packaging environments. Because these containers are produced using highly controlled draw and redraw processes, their shape and size remain stable, allowing them to function smoothly on conveyors, sealers, and labeling systems. Zhoushan Sinda Machinery Co., Ltd. designs its 2-piece DRD Can Lines to integrate efficiently with Easy Open-End (EOE) Production Lines, Metal Lids & Bottom Production Lines, and Food Tin Can Lines. This compatibility supports streamlined operations, reduced downtime, and reliable output in large-scale canning factories. During transportation, uniform can dimensions also allow for predictable stacking patterns, reducing wasted space and improving logistics efficiency.

Enhanced Protection for Food, Chemical, and Aerosol Products

Various industries rely on DRD cans due to their ability to protect contents from contamination, oxygen entry, and physical damage. In the food sector, the cans can be used for products requiring thermal processing, such as canned meats, soups, or ready meals. The seamless internal surface supports hygienic storage and helps maintain freshness throughout shelf life. For chemicals and industrial products, the sturdy structure prevents leaks even when the content is volatile or sensitive. Meanwhile, the aerosol industry depends on DRD cans for their ability to withstand internal pressure. Zhoushan Sinda Machinery Co., Ltd.’s Aerosol Dome & Cone Line integrates with the DRD body to create complete aerosol can systems suitable for personal care, household, and industrial applications.

Efficiency in Transportation Through Predictable Packaging Performance

The packaging and transportation stages depend heavily on predictable container behavior. Because DRD cans exhibit consistent structural characteristics, they stack evenly and remain stable even when exposed to varying temperatures or mechanical stress. Their lightweight but durable construction helps reduce transportation costs without compromising the safety of the packaged goods. Zhoushan Sinda Machinery Co., Ltd.’s expertise in metal packaging equipment supports manufacturers in producing DRD cans with precise tolerances that remain reliable throughout the logistics process. From warehouse handling to long-distance shipping, the containers preserve product integrity, reduce breakage or leakage, and support efficient pallet configuration.

Transportation Benefits of 2 Piece DRD Cans

| Benefit | Description |

|---|---|

| Efficient Stacking Ability | Uniform shape enhances pallet stability. |

| Reduced Risk of Leakage | Continuous wall structure supports safe long-distance transport. |

| Lightweight Construction | Helps lower shipping costs. |

| Compatibility with Automated Logistics Systems | Stable dimensions improve handling efficiency. |

Integration with Advanced Metal Packaging Machinery for Improved Output

The advantages of DRD cans are supported by the advanced manufacturing systems provided by Zhoushan Sinda Machinery Co., Ltd. The company’s portfolio—covering 2-piece DRD Can Lines, EOE Production Lines, Duplex Slitter machines, Chemical Tin Can Lines, Aerosol Dome & Cone Lines, and Metal Lids & Bottom Production Lines—ensures that manufacturers can implement complete and efficient production solutions. These integrated systems enhance overall equipment coordination, allowing for streamlined production, reduced material waste, and stable product quality. When these cans enter the packaging and transportation stages, the precision in forming and assembly provides dependable performance across diverse industrial applications.

English

English عربى

عربى русский

русский