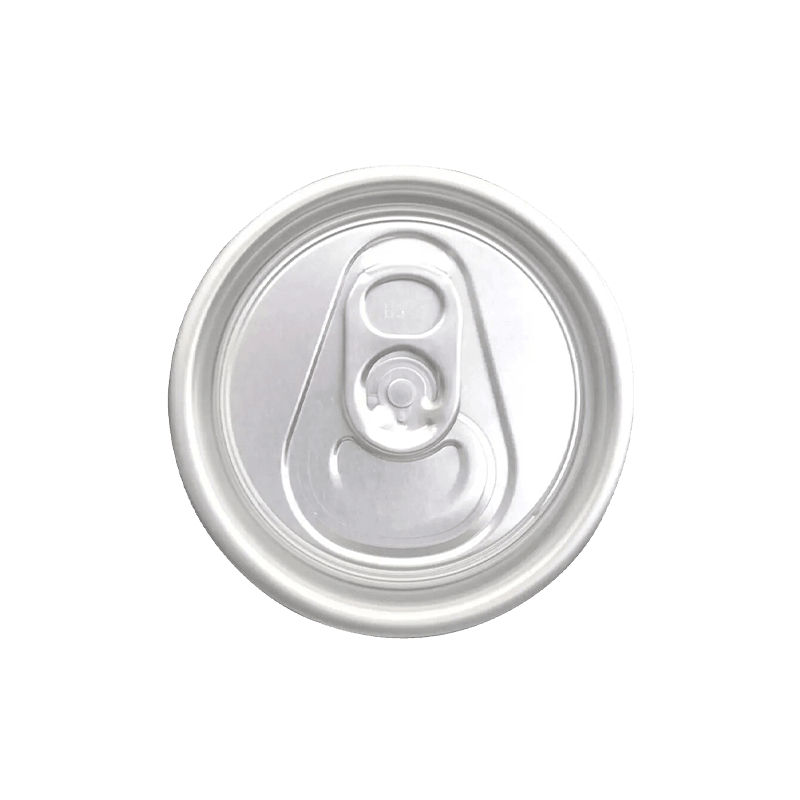

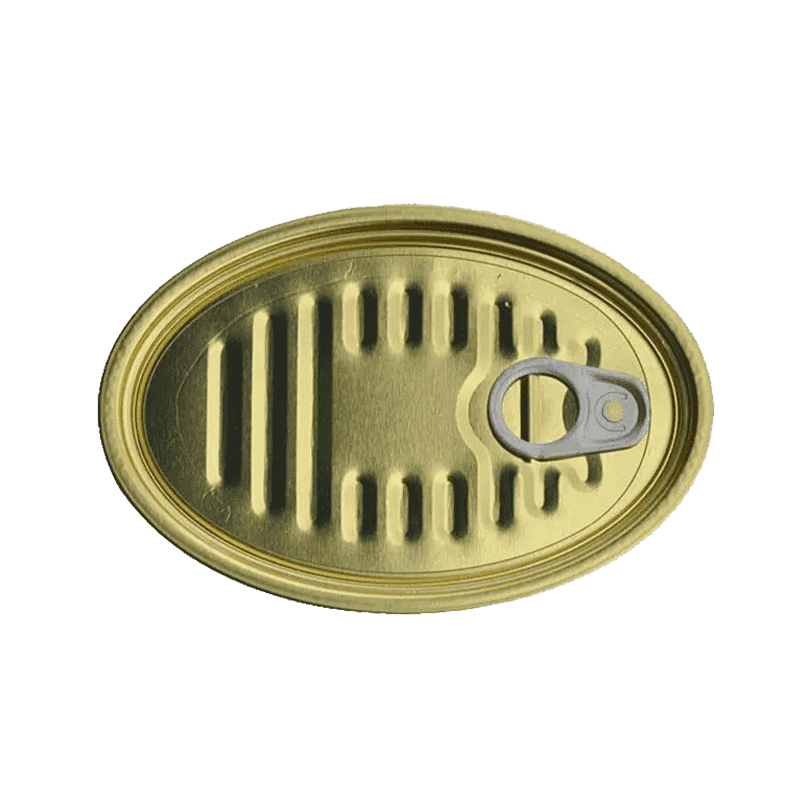

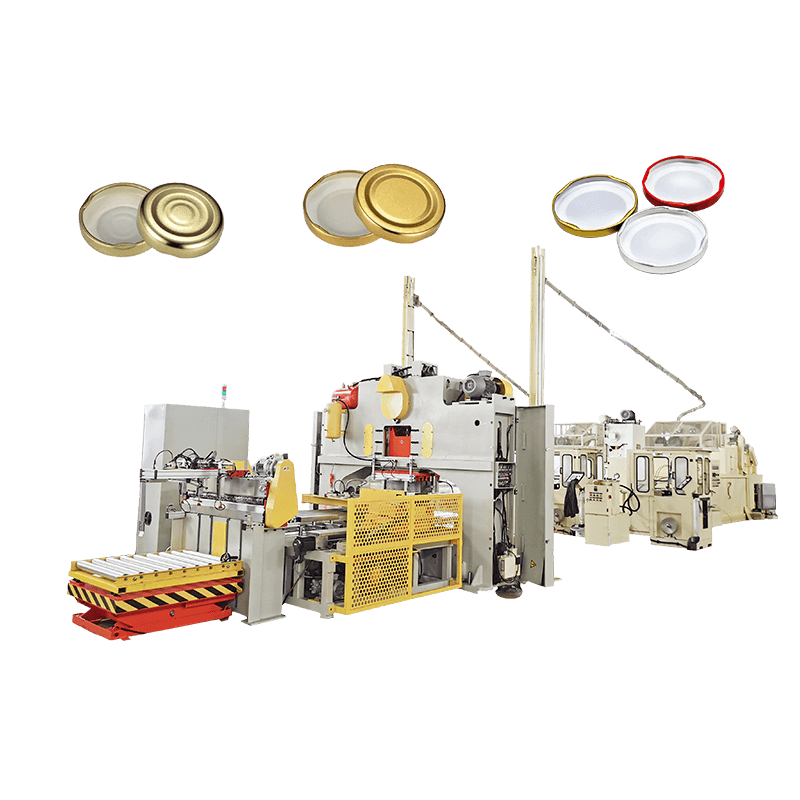

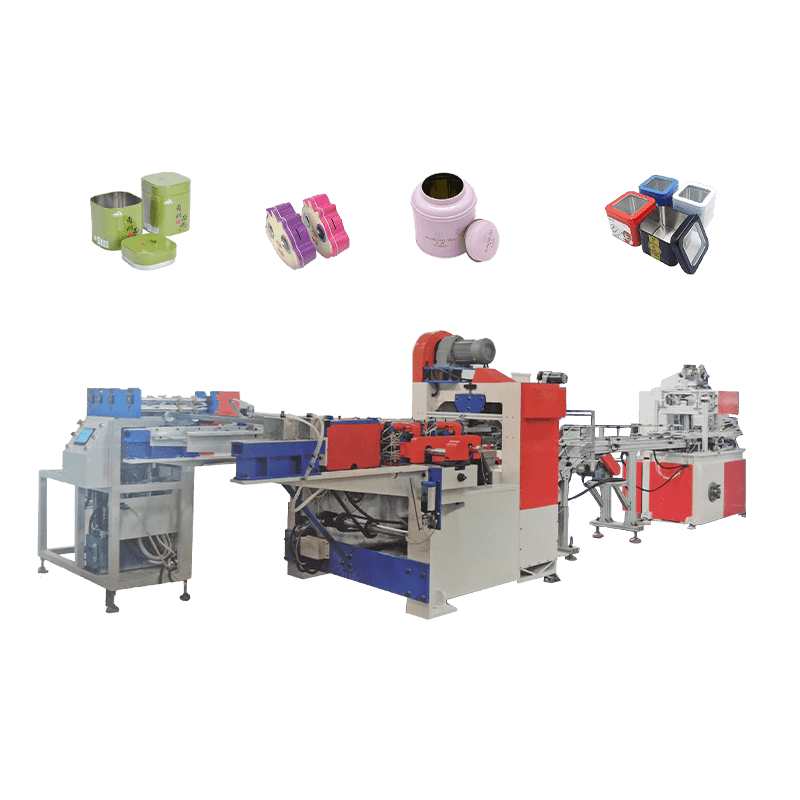

The EOE complete production line consists of 2 parts, the basic shells (normal ends) line and the EOE conversion line (scoring, ring pull tab making...).

Easy Open End (EOE) Production Line

Product Description

|

Model |

Pressure |

EOE size |

Number of lanes |

Capacity |

|

SDP-80A |

800 |

52-99 |

1 |

150-200 |

|

SDP-100B |

1000 |

52-99 |

1-2 |

300-600 |

|

SDP-125A |

1250 |

52-153 |

1-2 |

300-600 |

|

SDP-125B |

1250 |

52-99 |

2-4 |

800-1600 |

-

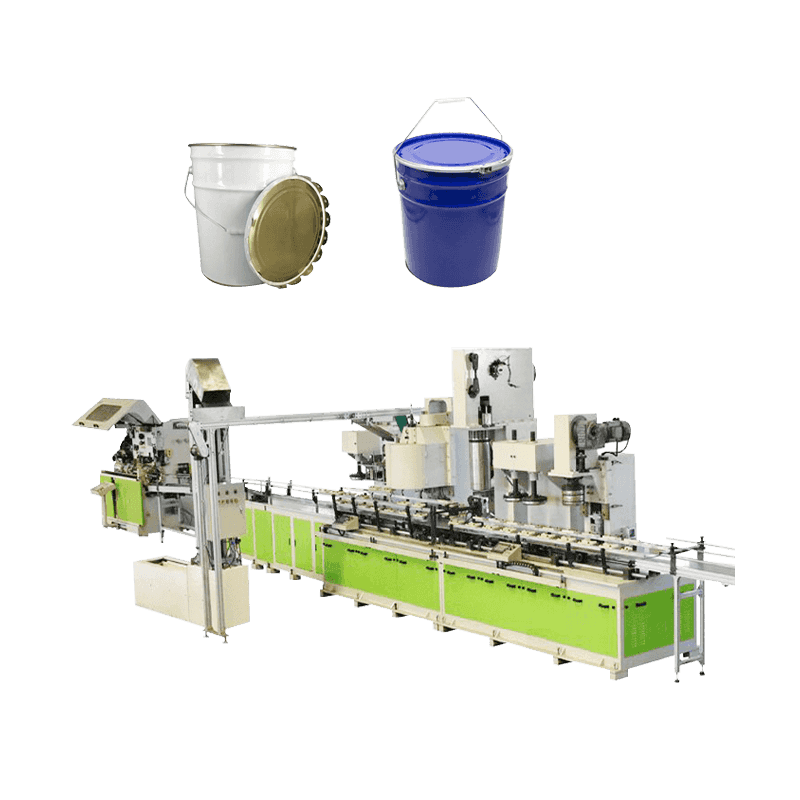

Introduction to Metal Lid Production Lines Metal lid production lines are specialized manufacturing systems used to produce lids for cans, containers, and other packaging applications. These lines int...

READ MORE -

Understanding the 3-Piece Food Tin Can Production Process Before discussing fault diagnosis, it is essential to understand the key stages involved in the production of 3-piece food tin cans. The proce...

READ MORE -

Introduction to 2-Piece DRD Can Production Line The 2-piece DRD (Drawn and Redrawn) can production line is a manufacturing process used to produce aluminum cans, commonly used for beverages and other ...

READ MORE

Impact of the Stamping Process on the Quality of the Easy-Open End in Modern Manufacturing

Understanding the Role of Stamping in the easy open end production line

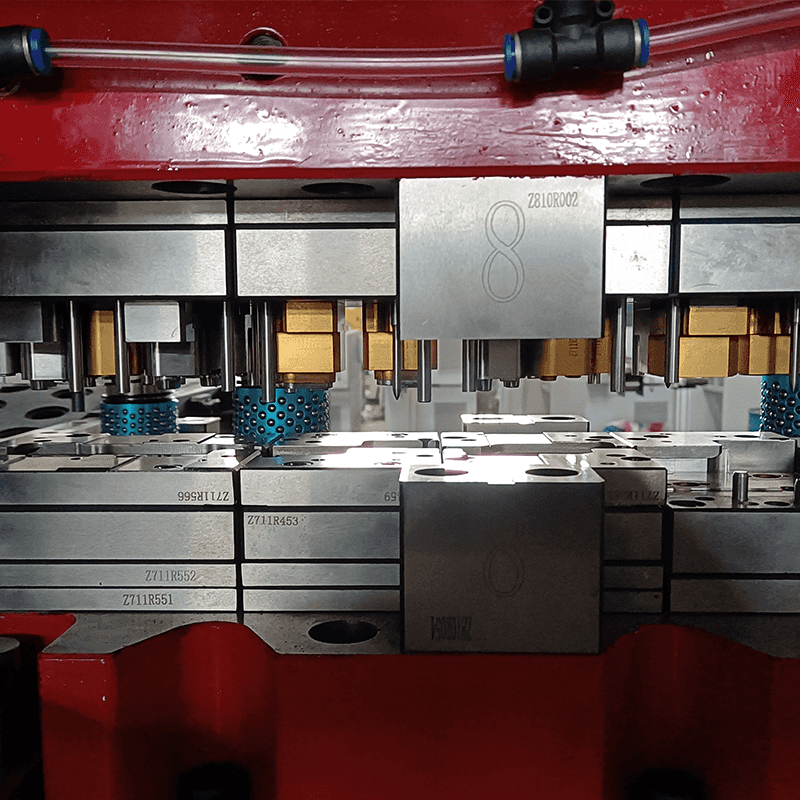

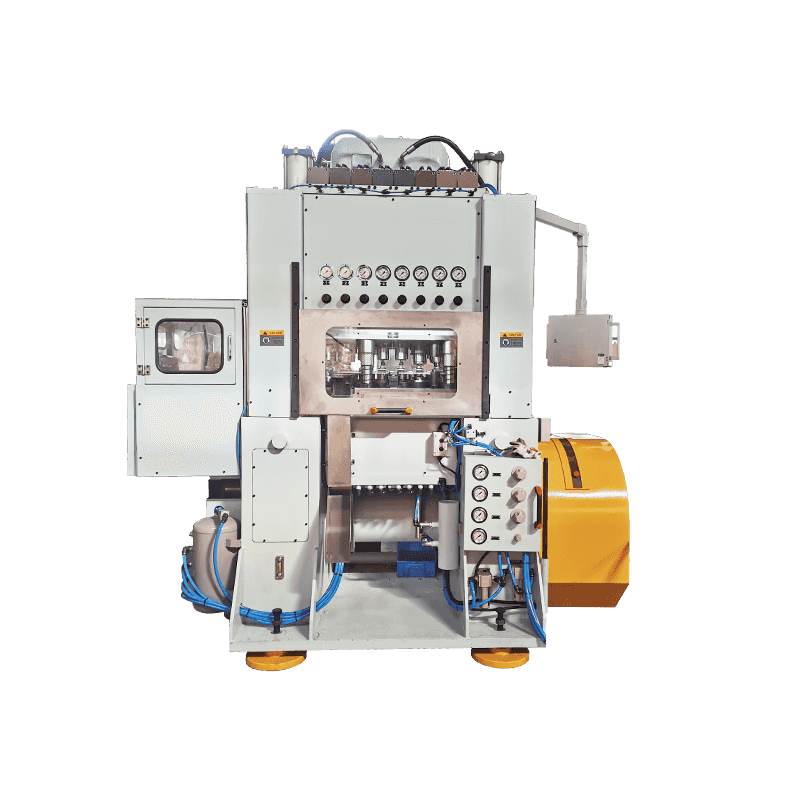

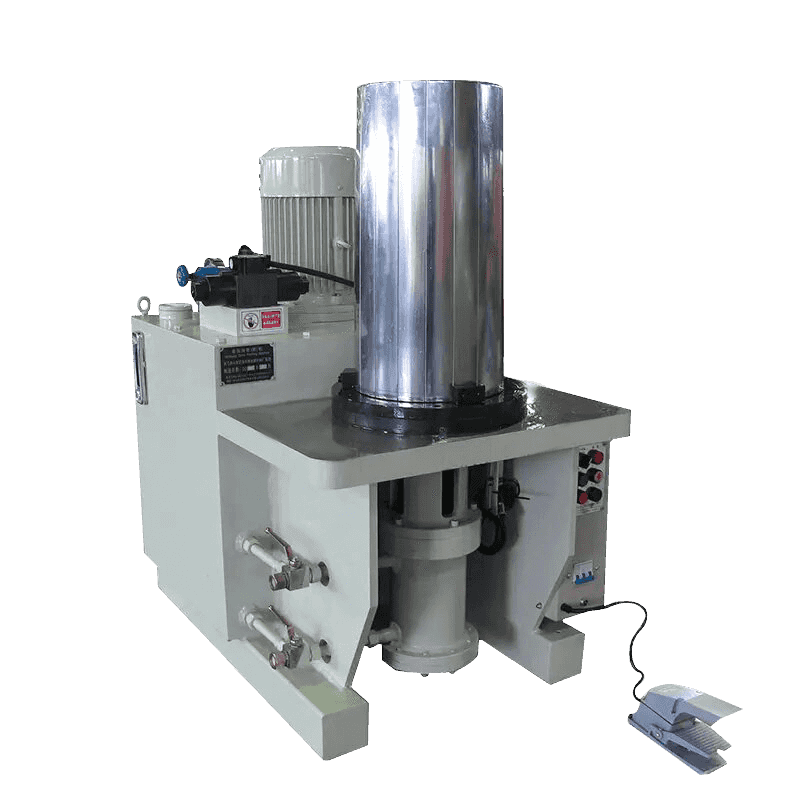

The stamping process occupies a core position in the easy open end production line because it defines critical structural features such as the score depth, rivet formation, and panel geometry. As a professional manufacturer in metal packaging machinery, Zhoushan Sinda Machinery Co., Ltd. incorporates stamping systems into its Easy Open-End (EOE) Production Lines with attention to tooling precision, material flow, and process stability. In rectangular, round, and shaped EOE manufacturing, stamping is responsible for cutting, forming, and shaping the lid into its functional configuration, establishing the foundation for opening performance, safety, and production efficiency. Since EOE structures require controlled weakening around the score and durable rivet formation to attach the pull tab, stamping accuracy becomes essential to maintain consistent quality across large production volumes.

Material Behavior Under Stamping Forces

During the stamping stage, the metal sheet—typically aluminum or tinplate—undergoes deformation under controlled pressure. The behavior of the metal directly affects the final strength and stability of the easy-open end. Materials with different thicknesses, coatings, and strength grades react differently to deformation, which makes scientific adjustment of stamping pressure necessary. In the production systems designed by Zhoushan Sinda Machinery Co., Ltd., equipment is engineered to deliver stable force distribution to prevent issues such as micro-cracks, over-stretching, or inconsistent hardness. Material flow must remain balanced so that the score area does not become too weak or too resistant. Incorrect material behavior caused by improper stamping pressure or misaligned tooling will lead to failure modes such as tear-off defects, incomplete opening, or tab detachment.

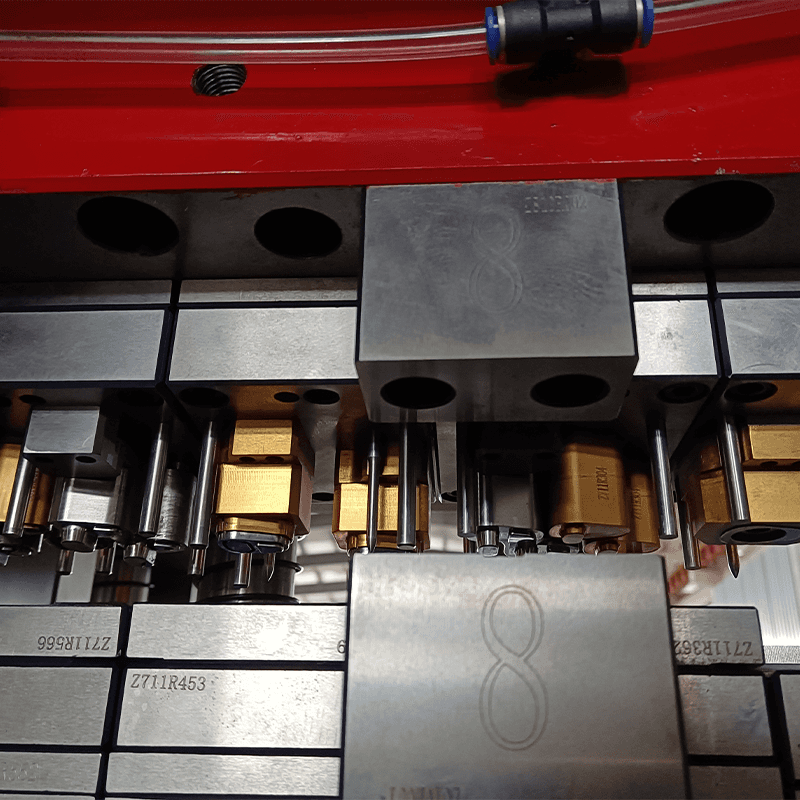

Tooling Precision and Its Influence on End Quality

Tooling design is another determinant of stamping quality because the dies, punches, and scoring elements shape the EOE and define its functional lines. In particular, scoring depth tolerance must remain very tight to ensure the can lid opens smoothly while maintaining enough strength to withstand internal pressure. Manufacturers such as Zhoushan Sinda Machinery Co., Ltd. implement CNC-machined tools and refined surface treatments to reduce friction, minimize wear, and maintain long-term dimensional accuracy. Tooling misalignment or wear will gradually alter score consistency, affect rivet integrity, and reduce sealing performance. As a result, regular maintenance and precise calibration become necessary components of maintaining stable quality outcomes during continuous production.

Comparison Table of Key Stamping Parameters Affecting Quality

Below is an illustrative table summarizing core stamping parameters and their influence on the easy-open end structure:

| Parameter | Impact on EOE Quality |

|---|---|

| Stamping Force | Affects structural integrity, score uniformity, and rivet strength. |

| Tooling Alignment | Determines precision of scoring, forming accuracy, and opening efficiency. |

| Material Thickness | Influences deformation behavior and ability to maintain pressure resistance. |

| Lubrication Condition | Affects friction, wear rate of tooling, and surface finish of the lid. |

| Die Clearance | Controls cutting edge quality and formation accuracy of the lid geometry. |

Surface Finish and Coating Integrity After Stamping

Another measurable influence of stamping quality is its effect on the surface coating and protective layers. EOE lids often include internal lacquer coatings or protective films that must remain intact to prevent corrosion and ensure product safety. High friction or excessive pressure during stamping may damage coating layers, leading to scratches, micro-abrasion, or edge exposure. Equipment offered by Zhoushan Sinda Machinery Co., Ltd. typically incorporates lubrication control and smooth tooling surfaces to ensure that coating integrity is preserved. This is particularly important for food tin can lines and chemical tin can lines, where corrosion resistance directly affects the shelf life and safety of packaged products.

Score Line Consistency and Its Role in Opening Performance

The score line is one of the most critical functional features of an easy-open end because it determines how the lid will tear along a predefined path. Consistent score depth and width are required to ensure that consumers can open the lid with reasonable effort while still maintaining structural strength before opening. A score that is too deep increases the risk of premature failure during transport, while a score that is too shallow makes the lid difficult to open. Stamping precision must therefore remain stable throughout the entire easy open end production line. Advanced scoring systems integrated into Sinda’s EOE equipment maintain consistent material removal and deformation through servo control and digital monitoring.

Rivet Formation Quality and Pull Tab Reliability

The rivet connects the pull tab to the lid and must possess stable mechanical strength so that the tab does not detach during opening. Rivet formation is achieved during stamping, where the metal is locally compressed to create a secure attachment point. Uneven pressure distribution, insufficient forming force, or tooling wear can lead to rivet thinning, cracks, or deformation. In automatic can-making lines produced by Zhoushan Sinda Machinery Co., Ltd., the rivet-forming stage is designed to ensure balanced material flow and stable shaping. Rivet quality directly influences user safety and the overall functionality of the easy-open end.

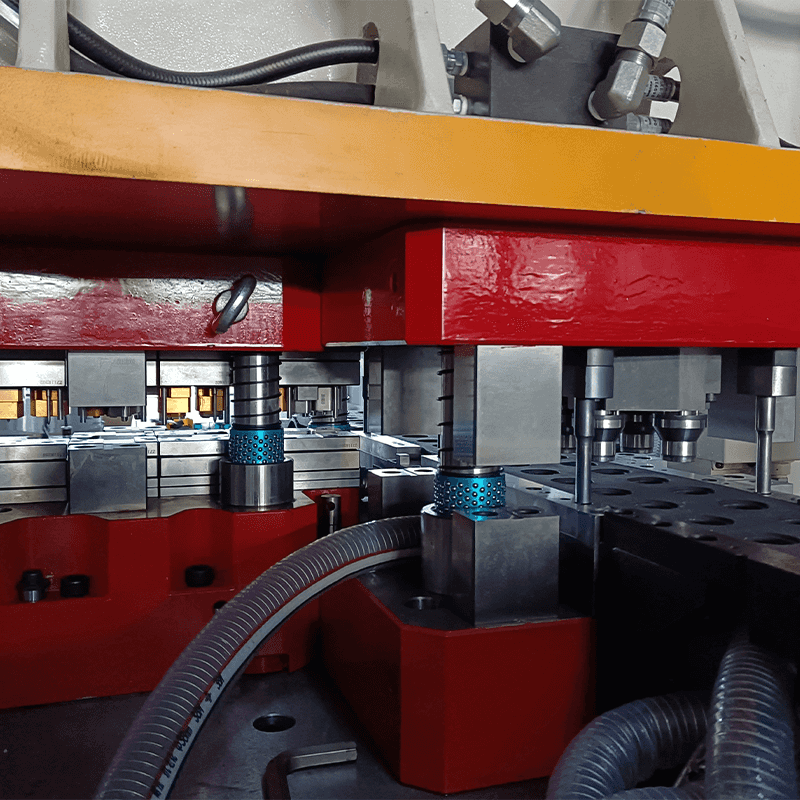

Impact of Multi-Stage Stamping on Dimensional Stability

Most easy-open ends are produced using multi-stage stamping, where each stage performs a specific shaping function. Each stage must be precisely synchronized to avoid cumulative errors that affect final lid geometry. For example, an off-center forming step in early stages may lead to later misalignment during tab attachment or curling. Multi-stage stamping systems used in EOE production lines require accurate servo motors, stable feeding mechanisms, and continuous monitoring. Zhoushan Sinda Machinery Co., Ltd. integrates these elements into its production machinery to maintain consistent dimensional accuracy throughout the entire forming cycle. Dimensional deviations may lead to sealing challenges or incompatibility with downstream can-body components.

Production Efficiency and Its Relationship with Stamping Stability

Stable stamping processes allow manufacturers to sustain high production speeds without compromising quality. Easy-open end production often involves high throughput, and any fluctuation in stamping performance may result in rejected batches or downtime. Tools and dies must endure continuous operation while maintaining their shape and alignment. Sinda’s production lines typically include durability-focused mechanical structures and automatic lubrication systems to support extended operation cycles. Higher production efficiency can only be achieved when stamping quality remains consistent over long periods, minimizing defect rates and ensuring that each EOE meets technical specifications.

Inspection Methods Used to Evaluate Stamping Quality

To ensure the reliability of easy-open ends manufactured through stamping, multiple inspection methods are applied. These include score depth measurement, rivet strength testing, dimensional checks, and coating integrity inspection. Modern inspection systems may incorporate vision technology to detect surface defects or deviations in shape. In many production lines supplied by Zhoushan Sinda Machinery Co., Ltd., automated inspection units are integrated to evaluate stamping results immediately after forming. This ensures prompt identification of issues and supports real-time adjustment to maintain consistent quality.

Table Summarizing Common Defects Related to Stamping and Their Causes

Below is an additional table outlining defect types and typical causes linked to stamping issues:

| Defect Type | Typical Cause |

|---|---|

| Score Cracking | Excessive stamping pressure or worn scoring tool. |

| Rivet Failure | Insufficient forming force or metal fatigue. |

| Surface Scratching | Poor lubrication or rough tooling surfaces. |

| Uneven Panel Shape | Misaligned dies during multi-stage forming. |

| Coating Damage | High friction or excessive tool contact. |

Integration of Stamping Technology in Advanced EOE Production Lines

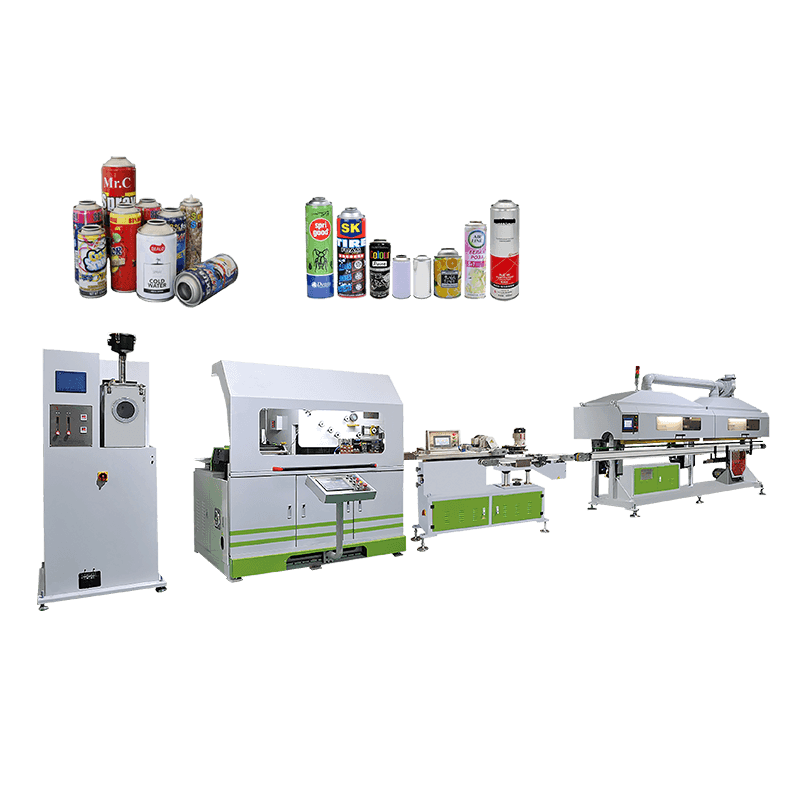

The continuous development of metal packaging machinery has made stamping technology increasingly advanced, especially in automated easy open end production line setups. Zhoushan Sinda Machinery Co., Ltd. integrates servo-driven presses, digital control systems, and modular workstation designs to enhance production consistency. These technologies allow better control of pressure distribution, feeding accuracy, and synchronization, which directly influences the quality of the EOE’s structural features. Enhanced automation also reduces manual intervention, improving reliability and supporting large-scale production for industries such as food, beverage, aerosol, and chemical packaging.

English

English عربى

عربى русский

русский