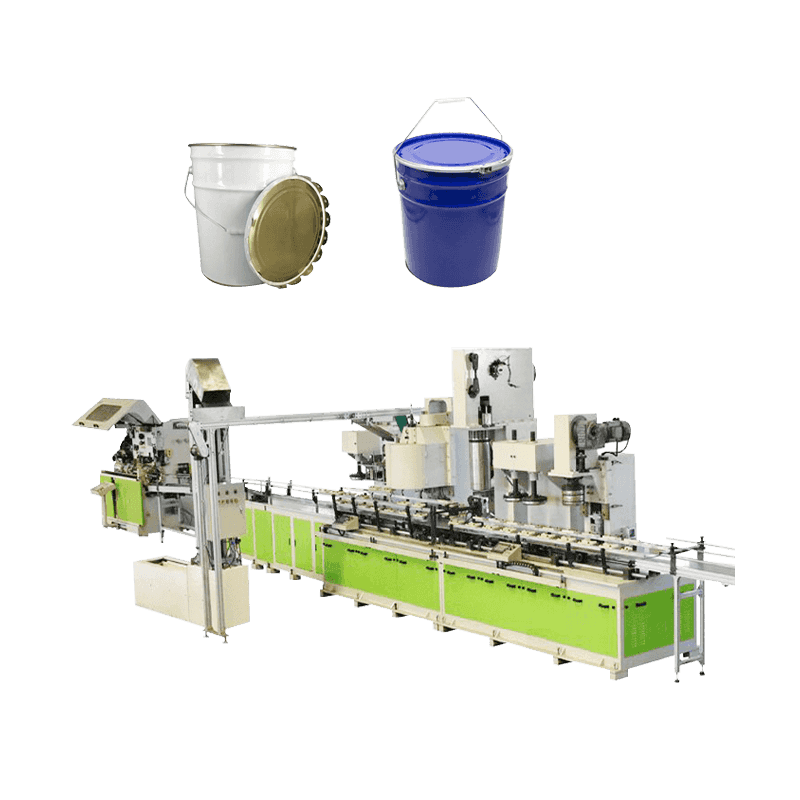

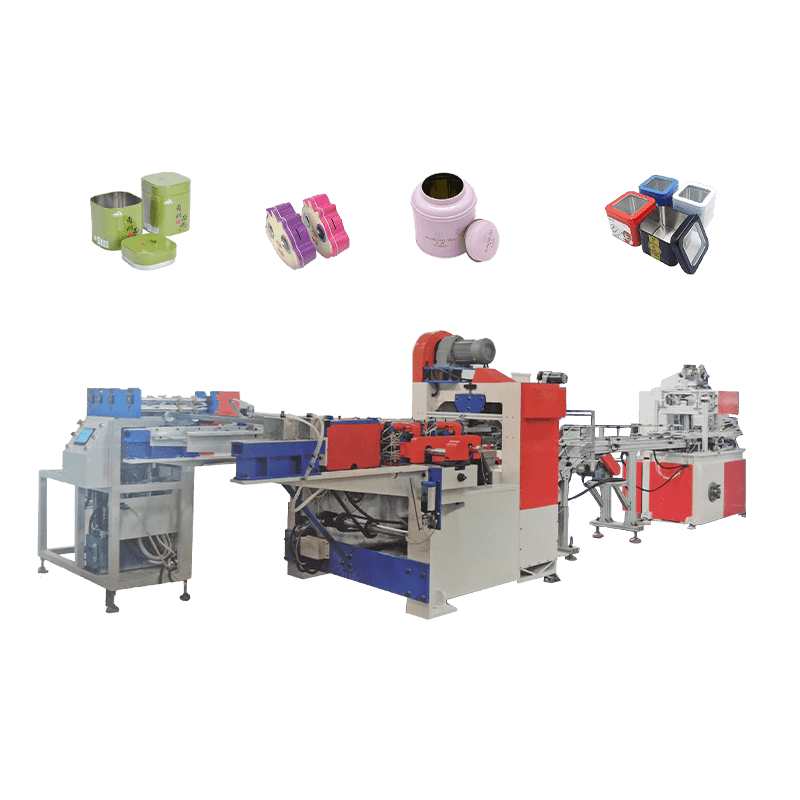

The automatic line is made up of a welding machine, a coating machine, a combination machine, one sealing machine, and conveyors, etc. Cans are automatically stand, expand, flange, curl, bead, and seal bottom integration after welded by the welding machine, comprehensive implementation of the mechanical and electrical integration. It can be used in sealing tinplate cans of can-making factories, such as paint, engine oil, etc. This automatic line is mainly used for 16L-20L conical pails. The whole line is highly automated, and the main motor adopts a frequency conversion motor with convenient adjustment. The whole line is operated by the PLC control with stable equipment performance and simple operation. The main parts are controlled by the servo. The sealing machine adopts 8 sealing rollers, which can be used for 5-layer sealing and also can be used for 7-layer sealing. Sealing quality is definitely reliable

Automatic Pail Production Line

Product Description

-

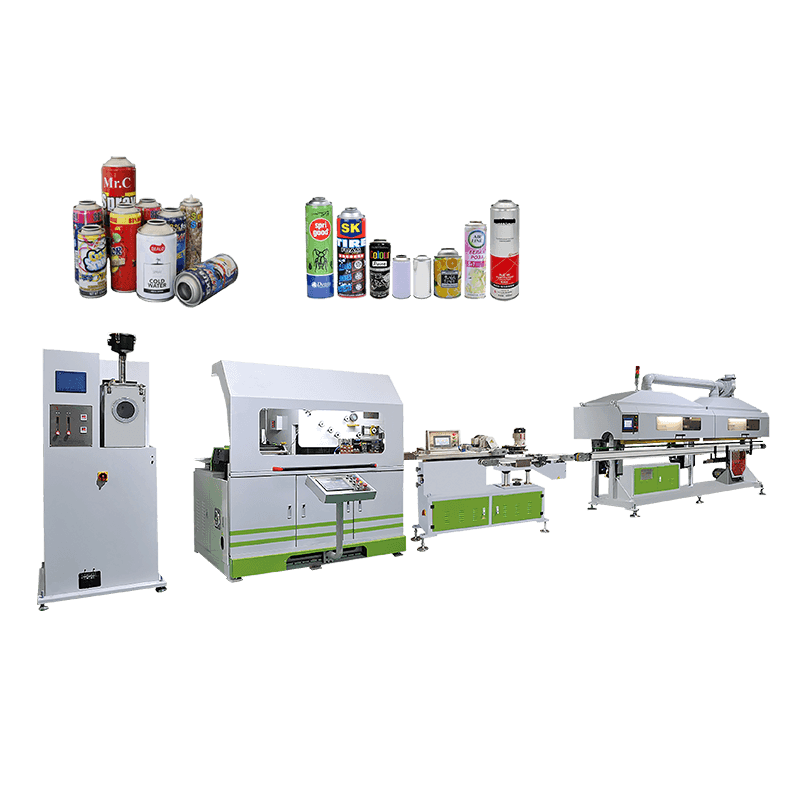

Introduction to Chemical Tin Can Making Machines Chemical tin can making machines are specialized equipment designed to produce tin-plated steel cans used for storing chemicals, solvents, and other in...

READ MORE -

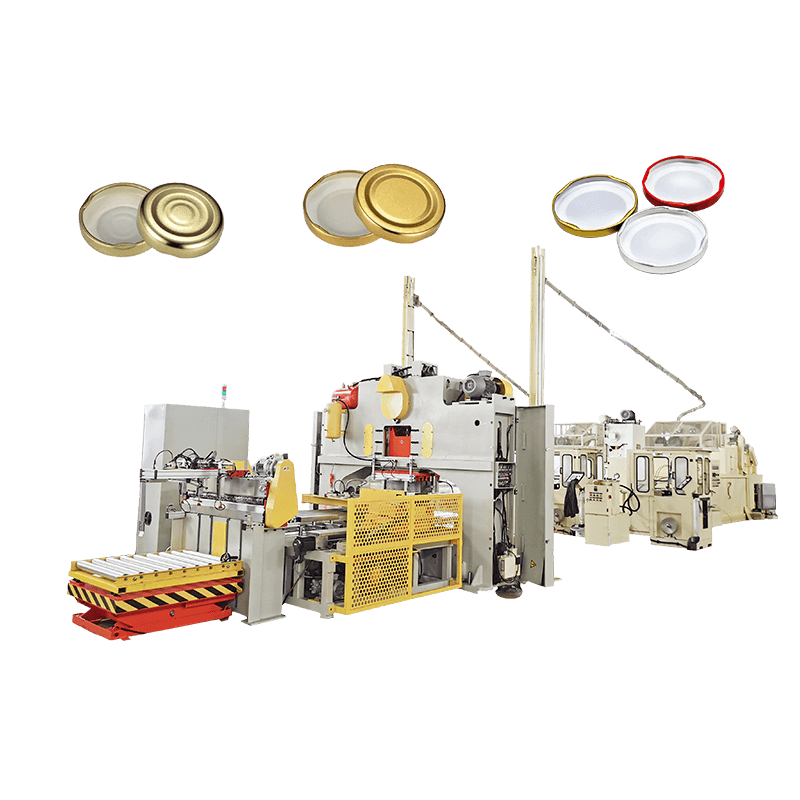

Introduction to Metal Lid Production Lines Metal lid production lines are specialized manufacturing systems used to produce lids for cans, containers, and other packaging applications. These lines int...

READ MORE -

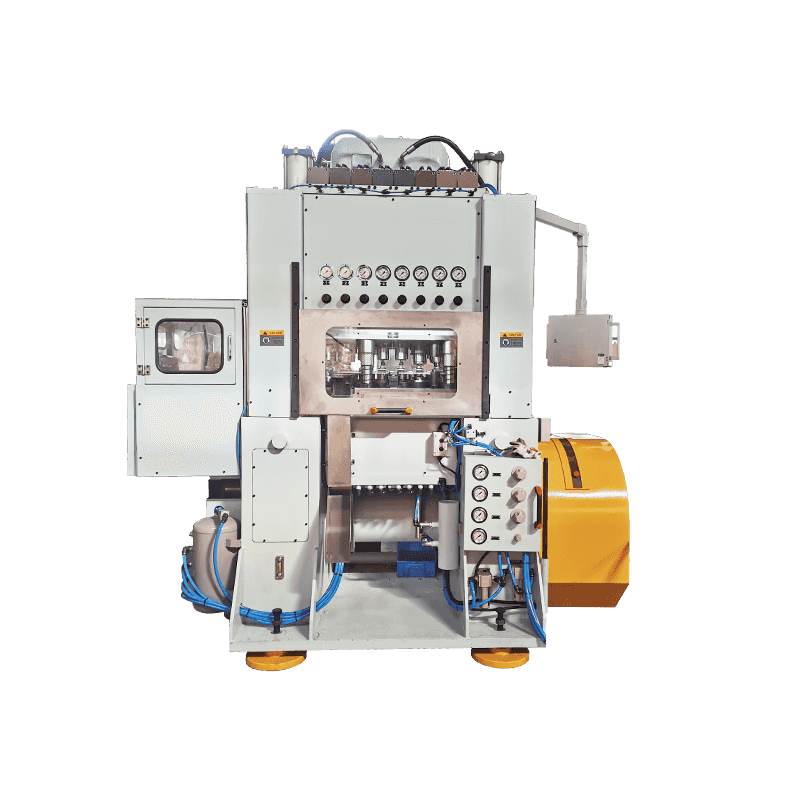

Understanding the 3-Piece Food Tin Can Production Process Before discussing fault diagnosis, it is essential to understand the key stages involved in the production of 3-piece food tin cans. The proce...

READ MORE

Why is Automatic Pail Production Line environmentally friendly?

1. Design concept of energy saving and emission reduction

At the beginning of its design, Automatic Pail Production Line fully considered the factors of energy saving and emission reduction. By optimizing the production process, reducing energy waste, and improving energy utilization efficiency, the production goals of low energy consumption and low emissions are achieved. For example, key equipment such as stamping, welding, and spraying on the production line all use advanced energy-saving technologies to ensure that energy consumption is reduced as much as possible while meeting production needs.

2. Efficient raw material utilization

Automatic Pail Production Line performs well in raw material utilization. Through precise process control and efficient equipment operation, it ensures full utilization of raw materials and reduces material waste. The production line also has the function of automatic recycling and reuse, and recycles scraps and waste generated during the production process, further improving the utilization rate of raw materials.

3. Clean production environment

Automatic Pail Production Line pays attention to the creation of a clean production environment during the production process. The production line is equipped with advanced environmental protection equipment such as dust removal, smoke removal, and noise reduction, which effectively reduces the emission of pollutants such as dust, exhaust gas, and noise during the production process. The production line also adopts a closed production mode to reduce pollution to the external environment.

4. Environmentally friendly spraying technology

In the barrel spraying process, Automatic Pail Production Line adopts environmentally friendly spraying technology. This technology uses water-based paint or low volatile organic compound (VOC) paint to replace traditional oil-based paint. Water-based paint and VOC paint have the characteristics of low pollution and easy degradation, which can greatly reduce the emission of harmful gases generated during the spraying process and reduce pollution to the environment.

5. Strict waste treatment

Automatic Pail Production Line strictly classifies and treats the waste generated during the production process. For recyclable waste, such as metal scraps, waste paint residues, etc., the production line will carry out special recycling and treatment to achieve resource reuse. For non-recyclable waste, the production line will properly handle it in accordance with relevant national laws and regulations to ensure that it does not pollute the environment.

6. Intelligent management and monitoring

Automatic Pail Production Line also has intelligent management and monitoring functions. By introducing advanced technologies such as the Internet of Things and big data, real-time monitoring and data analysis of the production process can be achieved. This not only helps to optimize the production process and improve production efficiency, but also can promptly discover and deal with potential environmental pollution problems, ensuring the environmental friendliness of the production process.

Maintenance and cleaning of Automatic Pail Production Line

1. Regular inspection and maintenance

Automatic Pail Production Line contains multiple complex mechanical parts and electrical systems, so regular inspection and maintenance are the basis for ensuring its normal operation. Maintenance personnel should regularly inspect key equipment such as punching machines, welding machines, spraying machines, etc. on the production line, including checking the lubrication of the equipment, the looseness of fasteners, the integrity of electrical components, etc. For any problems found, they should be repaired and replaced in time to ensure the normal operation of the equipment.

2. Clean production environment

The operating environment of the production line has an important impact on its performance and life. In order to keep the production line clean, the environment around the production line should be cleaned regularly, including the ground, equipment surface, conveyor belt, etc. Pollutants such as oil and dust on the production line should be removed in time to prevent them from corroding and damaging the equipment. The production line should also be well ventilated to avoid overheating of the equipment or the generation of harmful gases.

3. Equipment lubrication and maintenance

Many equipment on the Automatic Pail Production Line need to be lubricated and maintained to ensure their normal operation and extend their service life. Maintenance personnel should regularly check and replenish lubricating oil at the lubrication points of the equipment to ensure that the equipment is well lubricated. They should also regularly replace the vulnerable parts of the equipment, such as seals and bearings, to prevent equipment failures caused by component wear.

4. Inspection and maintenance of the electrical system

The electrical system is the core part of the Automatic Pail Production Line. Its stability and reliability directly affect the operation of the production line. Maintenance personnel should regularly inspect and maintain the electrical system, including checking the integrity of the cables, the contact of electrical components, the operating status of the controller, etc. Any electrical faults found should be repaired in time to ensure the normal operation of the electrical system.

5. Cleaning and maintenance of spraying equipment

Spraying equipment is an important part of the Automatic Pail Production Line. Its spraying quality directly affects the appearance and quality of the product. In order to keep the spraying equipment in good condition, the spraying equipment should be cleaned and maintained regularly. This includes cleaning the spray gun, nozzle and other parts to ensure that they are unobstructed; cleaning the oil and dust in the spray room to keep it clean; regularly replacing the spray equipment and paint to ensure the stability of the spray quality.

6. Establish a complete maintenance record

In order to track the maintenance of the equipment and predict the failure trend of the equipment, it is necessary to establish a complete maintenance record. The maintenance personnel should record the content, time, maintenance personnel and other information of each maintenance in detail, and regularly analyze and summarize the maintenance records, which will help to discover potential problems of the equipment and repair them in advance, thereby reducing the failure rate of the equipment and improving production efficiency.

English

English عربى

عربى русский

русский