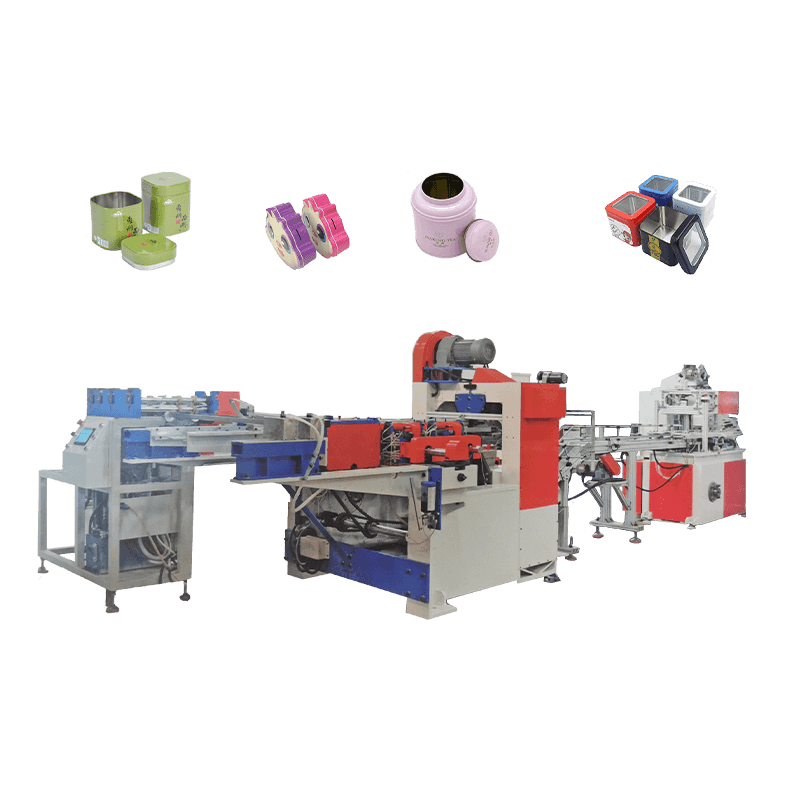

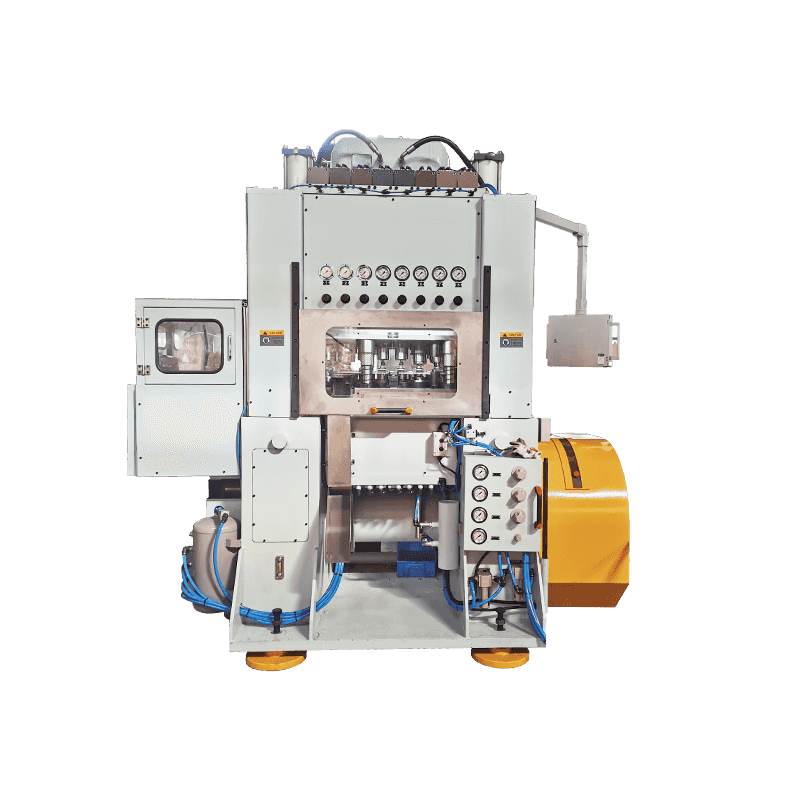

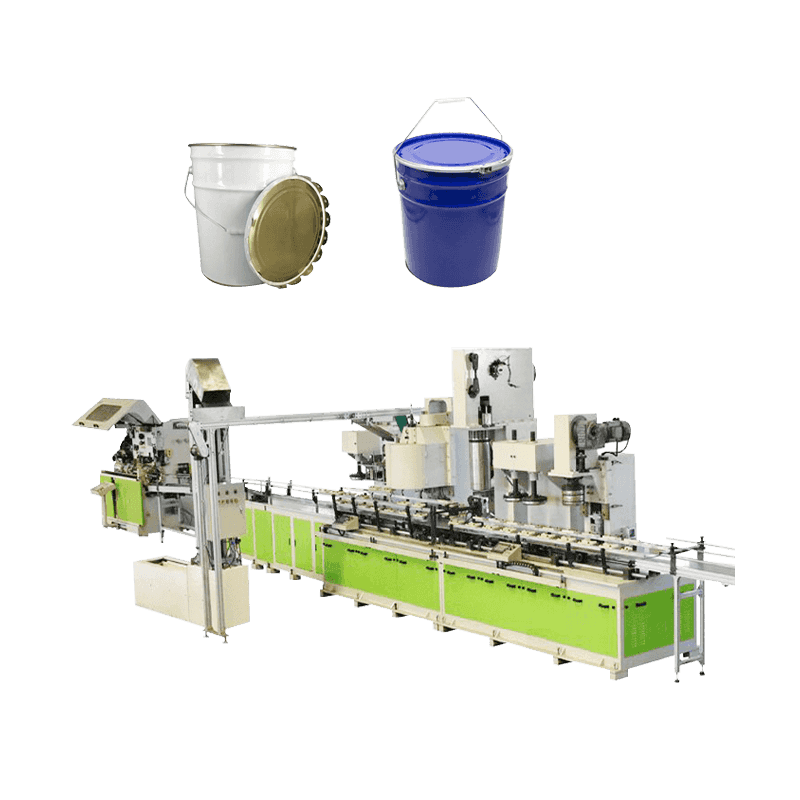

Full automatic from sheet feeding to bottom seaming. The automatic side seam locking machine combines edge pre-curling, corner cutting, side seam bending, side seam locking, flanging, and curling in one machine, efficient and safe!

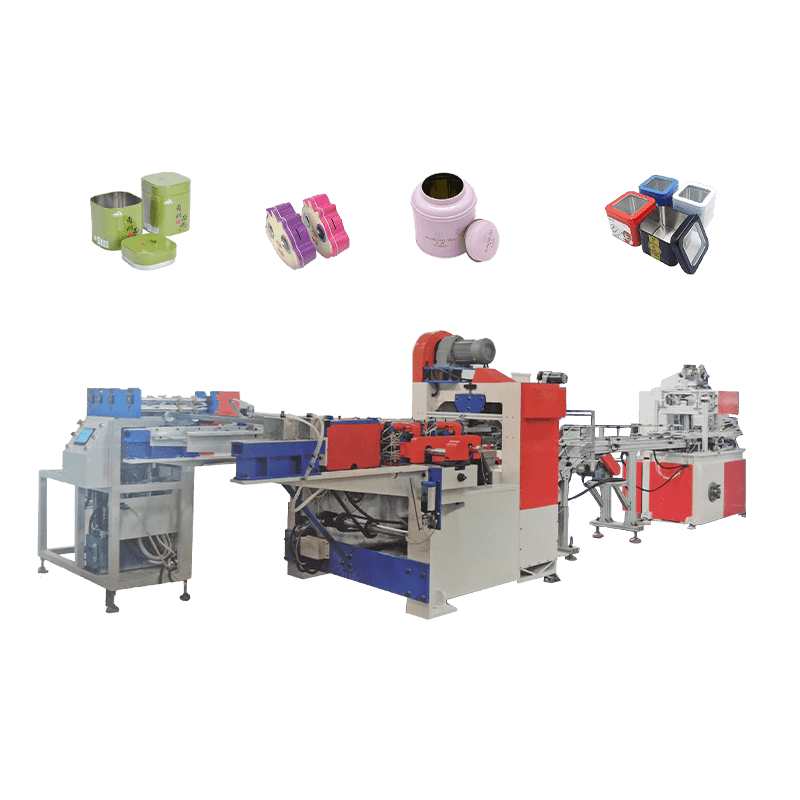

Fancy Tin Can Making Machines & Production Line

Product Description

|

Model |

Can Height |

Round Can Diameter (mm) |

Rectangular Can Diagonal |

Capacity |

|

SD-120 |

40-185 |

40-120 |

40-120 |

25-50 |

|

SD-200 |

55-290 |

65-190 |

70-200 |

25-50 |

|

SD-300 |

55-290 |

100-300 |

100-300 |

20-40 |

|

Suitable for making all shapes of cans (round, regular, octagonal, oval, heart...) |

||||

-

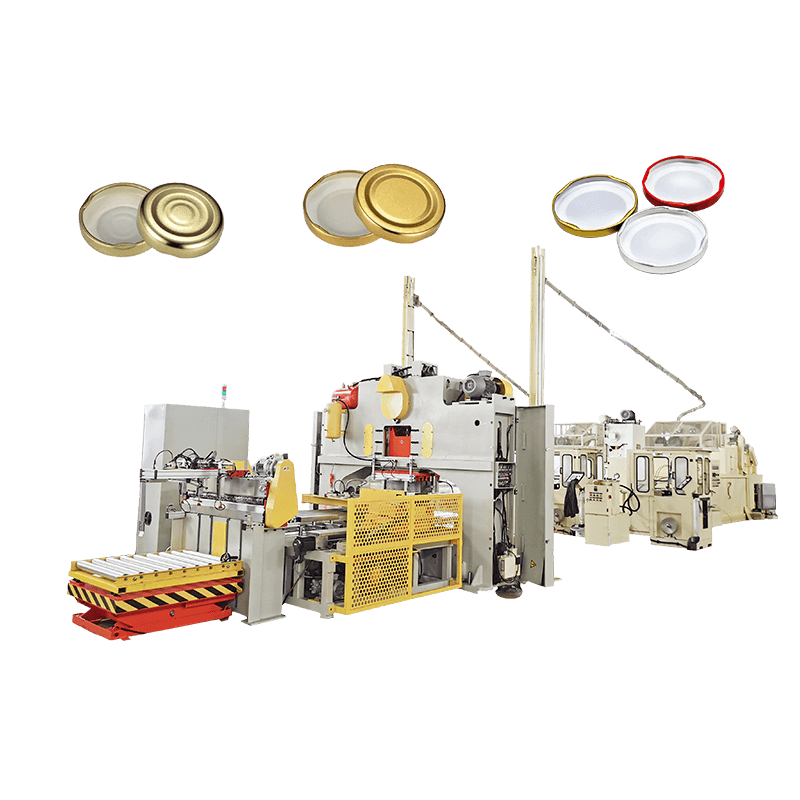

Introduction to Metal Lid Production Lines Metal lid production lines are specialized manufacturing systems used to produce lids for cans, containers, and other packaging applications. These lines int...

READ MORE -

Understanding the 3-Piece Food Tin Can Production Process Before discussing fault diagnosis, it is essential to understand the key stages involved in the production of 3-piece food tin cans. The proce...

READ MORE -

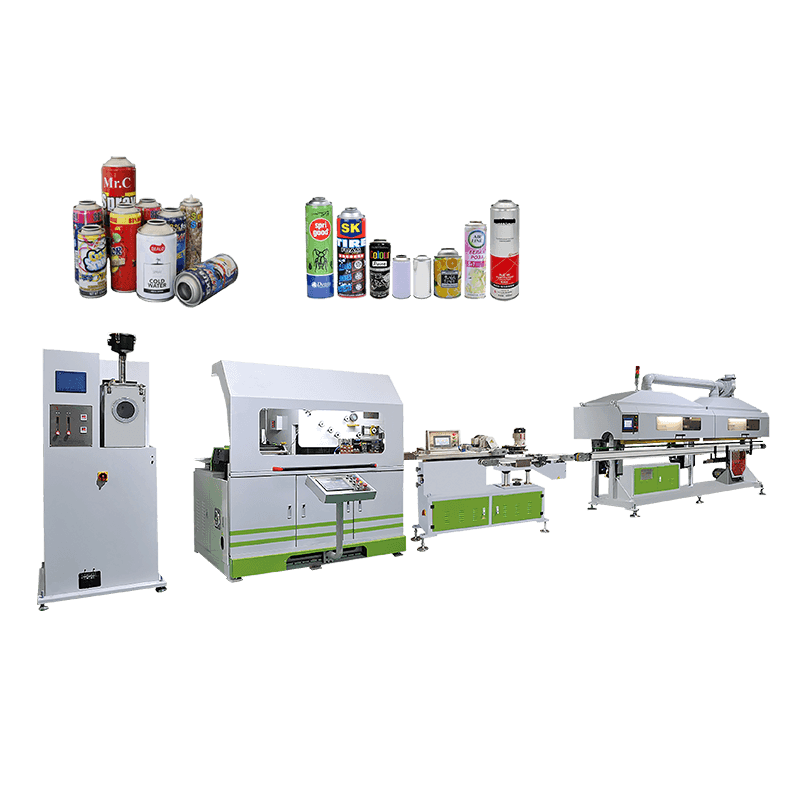

Introduction to 2-Piece DRD Can Production Line The 2-piece DRD (Drawn and Redrawn) can production line is a manufacturing process used to produce aluminum cans, commonly used for beverages and other ...

READ MORE

Automation Implementation Process of Fancy Tin Can Making Machines & Production Line

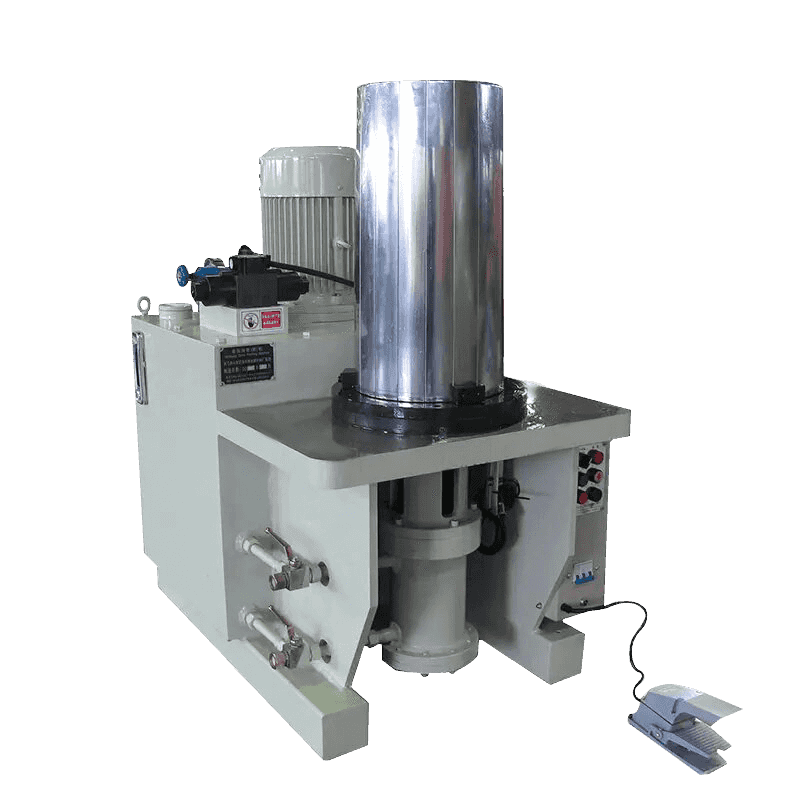

At the beginning of the design, Fancy Tin Can Making Machines & Production Line fully considered the integration of automation technology. From the automatic feeding, forming, welding of raw materials to coating treatment, inspection and packaging, each production link adopts advanced automation technology. These technologies include but are not limited to robotics, sensor technology, PLC control system, etc., which together constitute the core technical framework of the automated production line.

1. Application of Robotics

In Fancy Tin Can Making Machines & Production Line, robotics is an important means of achieving automation. Robots can automatically complete the processes of forming, welding, and handling tin cans according to preset programs and instructions. The application of robotics not only improves production efficiency, but also reduces the labor intensity of workers and reduces the impact of human factors on product quality.

2. Application of Sensor Technology

Sensor technology is an indispensable part of the automated production line. In Fancy Tin Can Making Machines & Production Line, sensors are widely used in raw material detection, production process monitoring, and product quality detection. By acquiring data from the production process in real time, the sensor can detect abnormal conditions in production in a timely manner and automatically adjust production parameters to ensure the stability of production and consistency of product quality.

3. The core role of the PLC control system

The PLC control system is the brain of the Fancy Tin Can Making Machines & Production Line, which is responsible for the coordination and control of the entire production line. The PLC control system receives data from various production links, processes and analyzes it, and then issues instructions to actuators such as robots and sensors to control the operation of the entire production line. The PLC control system has a high degree of reliability and stability, which can ensure the continuous operation and efficient production of the production line.

4. Optimization of automated production lines

With the continuous advancement of technology, the automation level of Fancy Tin Can Making Machines & Production Line is also constantly improving. By introducing advanced production management concepts and technical means, such as lean production and digital factories, the operating efficiency and product quality of automated production lines can be further optimized. At the same time, big data analysis and artificial intelligence technology can be used to deeply mine and analyze data in the production process, providing strong support for the optimization of production lines.

The automation journey of Fancy Tin Can Making Machines & Production Line is a process of continuous exploration and innovation. By introducing advanced automation technology and equipment, combining production practice and management needs, and continuously optimizing the operating efficiency and product quality of the production line, the automation upgrade of the tin can manufacturing industry has been realized. In the future, with the continuous advancement of technology and the continuous expansion of application fields, the automation level of Fancy Tin Can Making Machines & Production Line will become higher and higher, injecting new vitality into the development of the tin can manufacturing industry.

Application of Fancy Tin Can Making Machines & Production Line

In the modern packaging industry, tin cans, as a packaging container with unique charm and practical value, have been widely used in many fields. Fancy Tin Can Making Machines & Production Line provides strong support for the wide application of tin cans due to its efficient, precise and flexible production capacity.

1. In the food industry, tin cans have become an ideal packaging choice for many foods due to their excellent sealing and preservation properties. Fancy Tin Can Making Machines & Production Line can produce tin cans of various shapes, specifications and designs to meet the needs of different types of food. Whether it is sweets such as candy and chocolate, or dry goods such as nuts and dried fruits, these exquisite tin cans can add a unique charm to food. At the same time, tin cans can also effectively isolate the outside air and moisture, maintain the freshness and taste of food, and extend the shelf life.

2. The beverage industry is another important application field of tin cans. From traditional soda and juice to modern tea drinks, coffee, etc., tin cans have become the first choice of many consumers with their unique texture and elegant appearance. Fancy Tin Can Making Machines & Production Line can produce tin cans suitable for packaging according to the characteristics of different beverages. These tin cans not only have good sealing and corrosion resistance, but also can withstand a certain amount of pressure to ensure that the beverages are not damaged during transportation and storage. In addition, the exquisite appearance and personalized design of the tin cans can also attract consumers' attention and enhance brand image and market competitiveness.

3. With the continuous development of the cosmetics market, consumers have higher and higher requirements for packaging. Fancy Tin Can Making Machines & Production Line can produce tin cans of various shapes, colors and designs to meet the cosmetics industry's demand for fashionable and high-end packaging. These tin cans are not only exquisite in appearance, but also can effectively protect the ingredients and quality of cosmetics and prevent them from being affected by the external environment. At the same time, the environmental performance of tin cans is also in line with the cosmetics industry's pursuit of sustainable development. Therefore, more and more cosmetics brands have begun to choose tin cans as the packaging of their products.

4. In the gift industry, tin cans have become the ideal packaging for many souvenirs, collectibles and other gifts with their unique materials and exquisite appearance. Fancy Tin Can Making Machines & Production Line can produce tin cans of various shapes, sizes and designs according to customer needs to meet the needs of different occasions and uses. These tin cans can not only enhance the grade and value of gifts, but also bring a unique surprise and touch to the recipients.

English

English عربى

عربى русский

русский