Specification

| Parameter Category | Specification Content | Remarks / Additional Information |

|---|---|---|

| Production Capacity | 1,500–15,000 bottoms/hour | Depends on can type |

| Bottom Type | Flat, Concave, Beaded | Supports multiple can diameters |

| Material | Steel, Aluminum, Tinplate | Thickness 0.18–0.30 mm |

| Automation Level | Fully Automatic | High-speed production |

| Control System | PLC + HMI | Real-time monitoring and control |

| Power Requirement | 380V/50Hz | Customizable |

| Tooling Options | Interchangeable Dies | Supports different can sizes |

| Machine Footprint | 20–50 m² | Depends on layout |

| Quality Compliance | ISO9001, CE | International standards |

| Optional Features | Embossing, Printing | Enhances product appeal |

| Maintenance | Preventive maintenance schedule | Ensures long-term reliability |

| Safety Features | Emergency stop, Overload protection | Complies with CE safety standards |

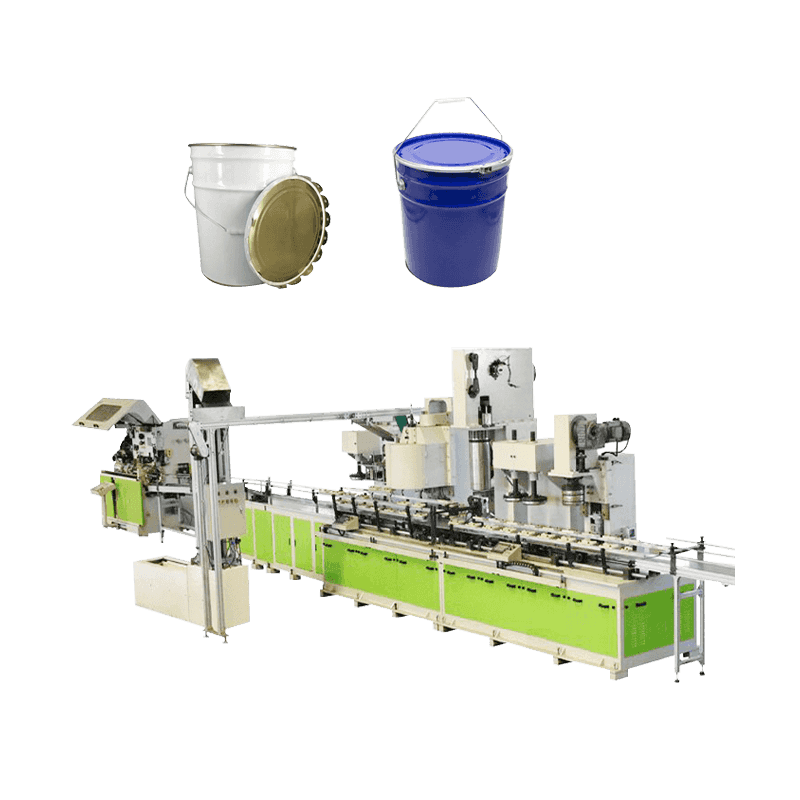

| Application | Food, Beverage, Chemical | Industrial production |

Application

Food Cans

Used to produce can bottoms for food products including vegetables, fruits, seafood, and ready meals, ensuring durability and leak-proof performance.

Beverage Cans

Applicable for beverage cans, providing stable bases to support stacking, storage, and transport of carbonated and non-carbonated drinks.

Industrial Packaging

Supports production of bottoms for chemical, paint, and lubricant cans, ensuring strong and secure containment of industrial materials.

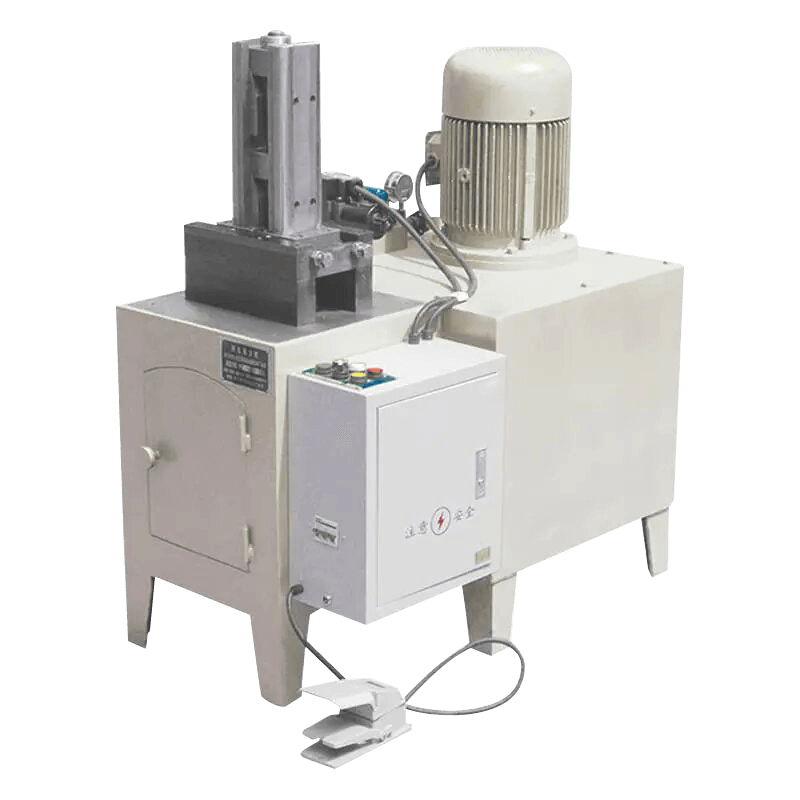

Advantage

Strong and Leak-Proof

Produces durable can bottoms that provide structural support and prevent leakage, ensuring product safety during transport and storage.

High Productivity

Capable of producing large quantities of can bottoms efficiently, reducing cycle times and labor requirements.

Compatibility

Designed to match various can sizes and shapes, allowing flexibility for different production lines and packaging needs.

English

English عربى

عربى русский

русский