Specification

| Parameter Category | Specification Content | Remarks / Additional Information |

|---|---|---|

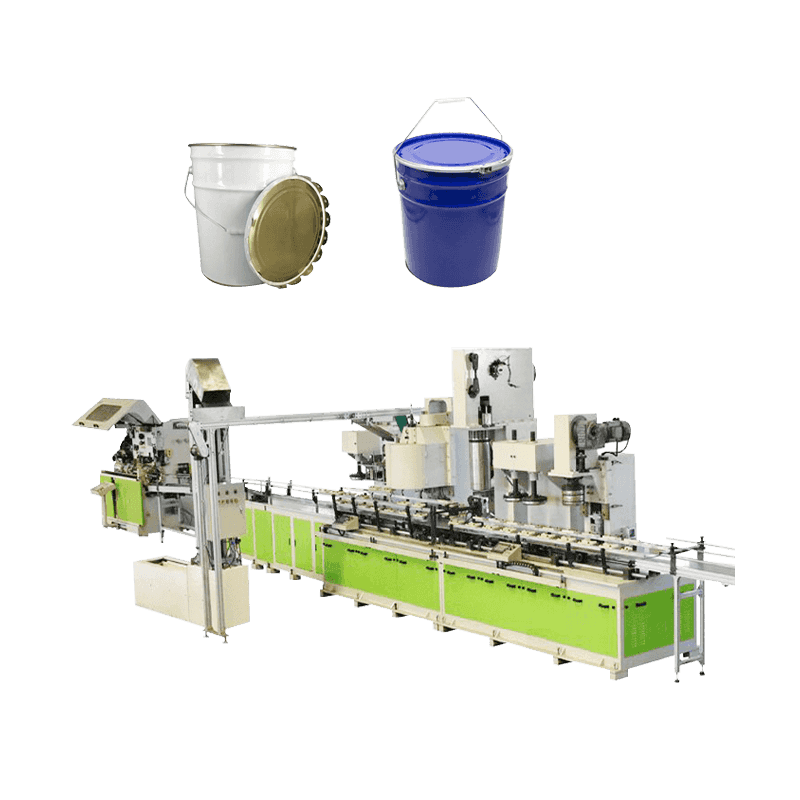

| Production Capacity | 1,500–20,000 cans/hour | Depends on can size and material |

| Can Shape | Round, Square, Rectangular | Supports custom dimensions |

| Material | Tinplate, Steel | Thickness 0.18–0.30 mm |

| Automation Level | Semi-Automatic / Fully Automatic | Optional integration with labeling or filling machines |

| Control System | PLC + HMI | Real-time monitoring with fault alarms |

| Power Requirement | 380V/50Hz | Adjustable for local voltage requirements |

| Tooling Options | Interchangeable dies | For multiple can sizes and types |

| Footprint | 12–40 m² | Depends on line configuration |

| Compliance | ISO9001, CE, FDA | Meets international food packaging standards |

Application

Canned Food

Specialized for producing tin cans for food items such as vegetables, fruits, meat, seafood, and dairy products, maintaining food safety and shelf stability.

Ready-to-Eat Meals

Enables production of cans for ready meals, soups, and sauces, suitable for large-scale food processors aiming for long shelf life and easy transport.

Snack Packaging

Used for packaging nuts, candies, cookies, and other snack products, combining attractive design with protective tin material.

Advantage

Food Safety Compliance

Manufactures cans that meet food-grade standards, ensuring safe storage and extended shelf life for packaged food products.

Consistent Quality

Produces uniform cans with precise sealing, maintaining freshness and preventing contamination.

Flexible Sizes

Supports production of different can sizes to accommodate various food products, from soups to pet food.

English

English عربى

عربى русский

русский