Product Description

|

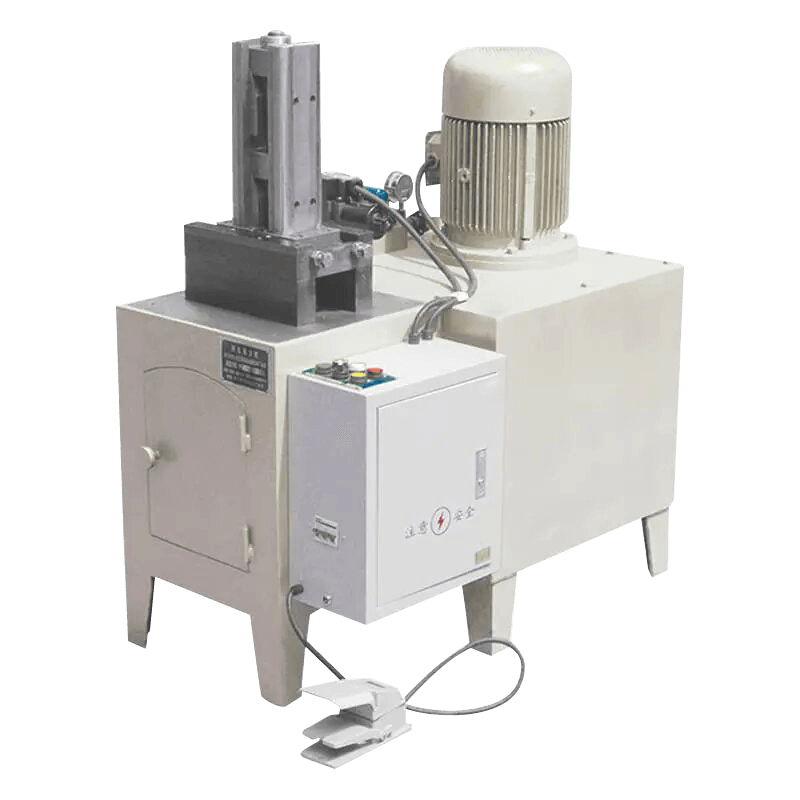

GT3B50-NF |

Necking+Flanging |

Tooling Numbers |

Capacity (ppm) |

Tin Can Diameter (mm) |

|

Necking+Flanging+Beading |

6-8 |

150-500 |

D52-99 |

|

|

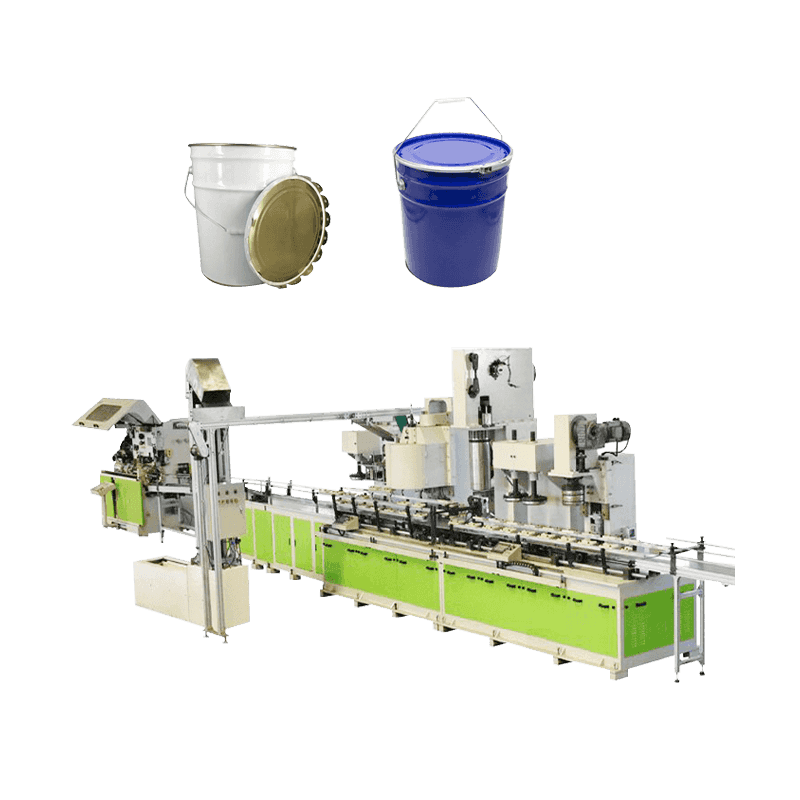

GT3B50-NFS |

Necking +Flanging+Seaming |

6-8 |

150-500 |

D52-99 |

|

Flanging+Beading+Seaming |

6-8 |

150-500 |

D52-99 |

|

|

GT3B90-FBS |

Flanging+Beading+Seaming |

4 |

150-500 |

D99-153 |

Application

Canned Food Production

Used for producing various canned foods, such as vegetables, meat, seafood, and other preserved food products, ensuring long shelf life and consistent quality.

Beverage Packaging

Suitable for beverage cans, including carbonated drinks, juices, teas, and other liquid refreshments, providing safe and leak-proof packaging for storage and transport.

Oil & Sauce Packaging

Used for packaging edible oils, sauces, ketchup, and other liquid or semi-liquid food products, maintaining product freshness and preventing contamination.

Ready-to-Eat Meals

Ideal for canned ready-to-eat meals, soups, and stews, offering convenience to consumers while ensuring safety, extended shelf life, and stable storage during distribution.

Specialty Food Cans

Capable of producing customized or special-shaped food cans to meet brand differentiation, marketing requirements, and unique consumer needs, supporting diverse product lines.

Advantage

-

High Efficiency: Ensures fast production, capable of handling hundreds of cans per minute.

-

Automation: Supports full or semi-automatic operation, reducing labor costs and improving consistency.

-

Precision: Maintains accurate can dimensions and uniform sealing for reliable packaging.

-

Versatility: Handles multiple can shapes and sizes, including round, rectangular, and specialty cans.

-

Material Compatibility: Works with tinplate, coated steel, and aluminum sheets of varying thicknesses.

-

Quality Assurance: Equipped with visual inspection, leak detection, and welding monitoring systems.

-

Durability: Built with robust mechanical components for long-term operation and low maintenance.

-

Flexibility: Modular design allows customization for production speed, can types, and automation level.

-

Safety: Integrated safety features such as emergency stops, overload protection, and safety guards.

-

Energy Efficiency: Optimized mechanical and electrical systems to reduce energy consumption.

-

Ease of Operation: PLC control and HMI touch screens allow easy parameter adjustments and monitoring.

-

Reduced Downtime: Quick mold change and automated feeding systems minimize production interruptions.

English

English عربى

عربى русский

русский