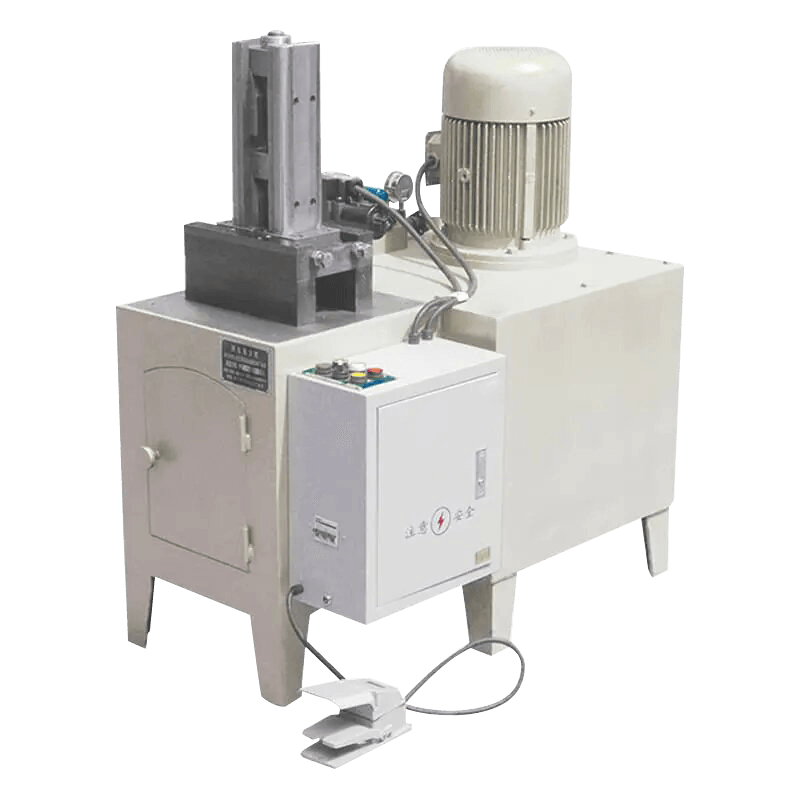

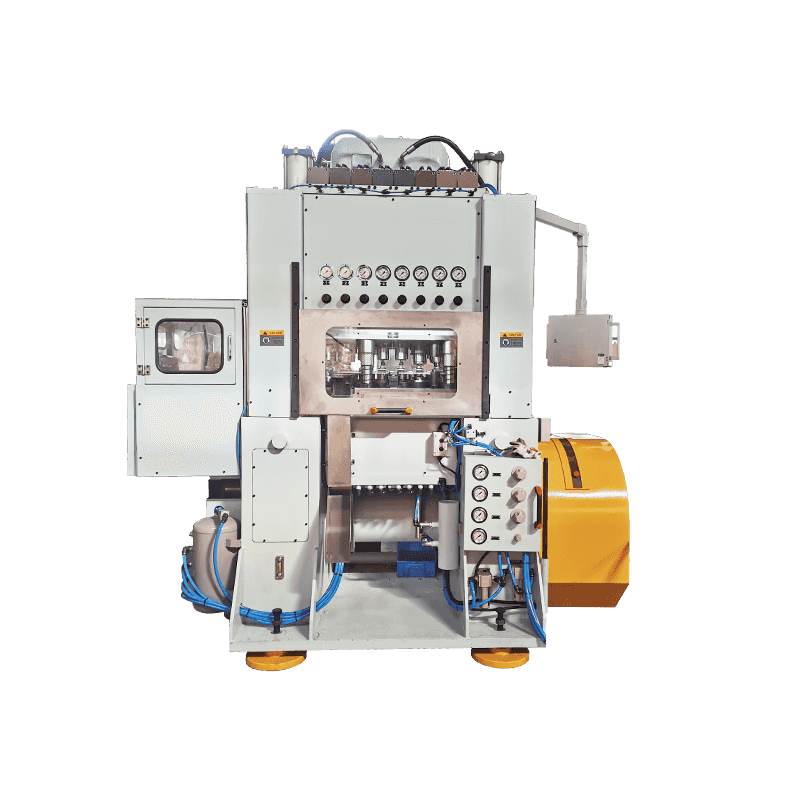

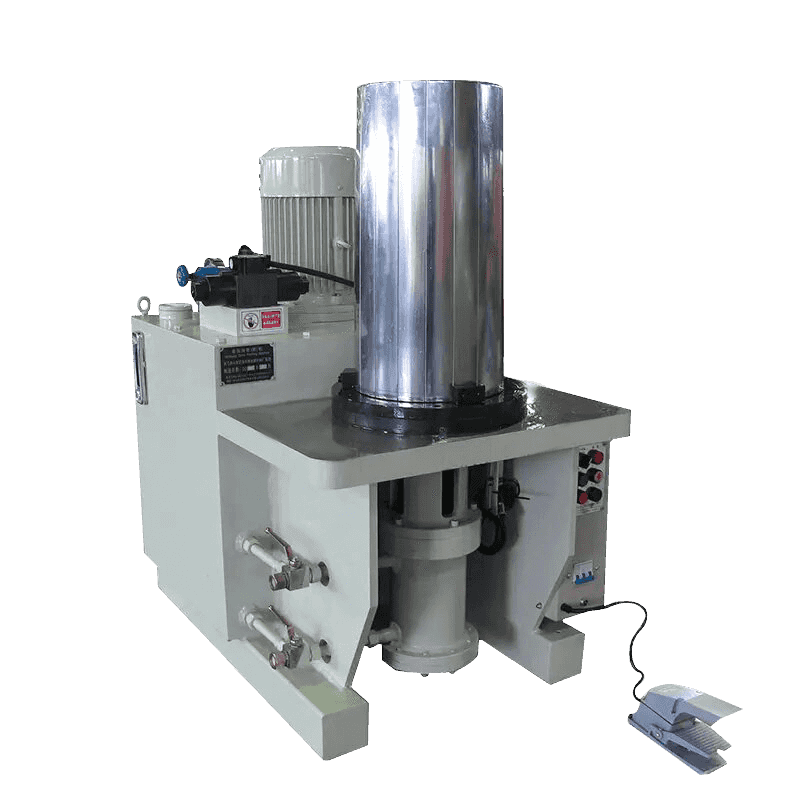

It is for rectangular shape forming. Semi-automatic rectangular tin can forming machine is mainly used to hydraulically form round cans into square, oval, or other cans of different shapes, and replace different molds, which can be applied to the forming of cans of different shapes. Semi-automatic rectangular tin can forming machine has the characteristics of smooth operation and good forming effect, and can be used to form different sizes and shapes cans by replacing different molds.

Rectangular Tin Can Forming Machine

Product Description

It is for rectangular cans forming

|

Can diameter |

≤330mm |

|

Can height |

≤400mm |

|

Sheet thickness |

0.18-0.5mm |

|

Production capacity |

10-20mm |

|

Dimension |

1150*800*750mm |

|

Power |

2.5kw |

-

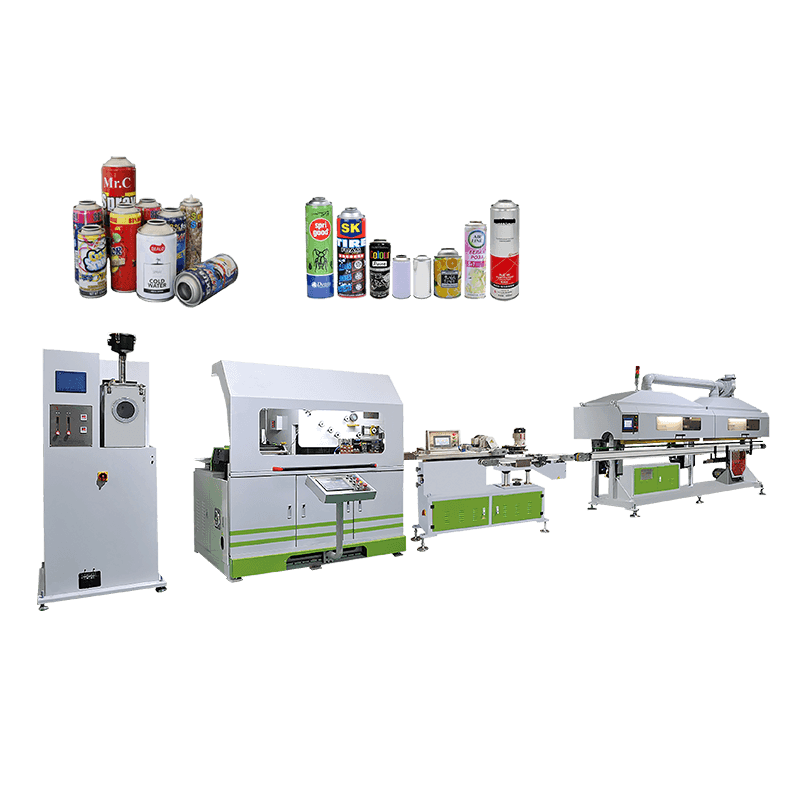

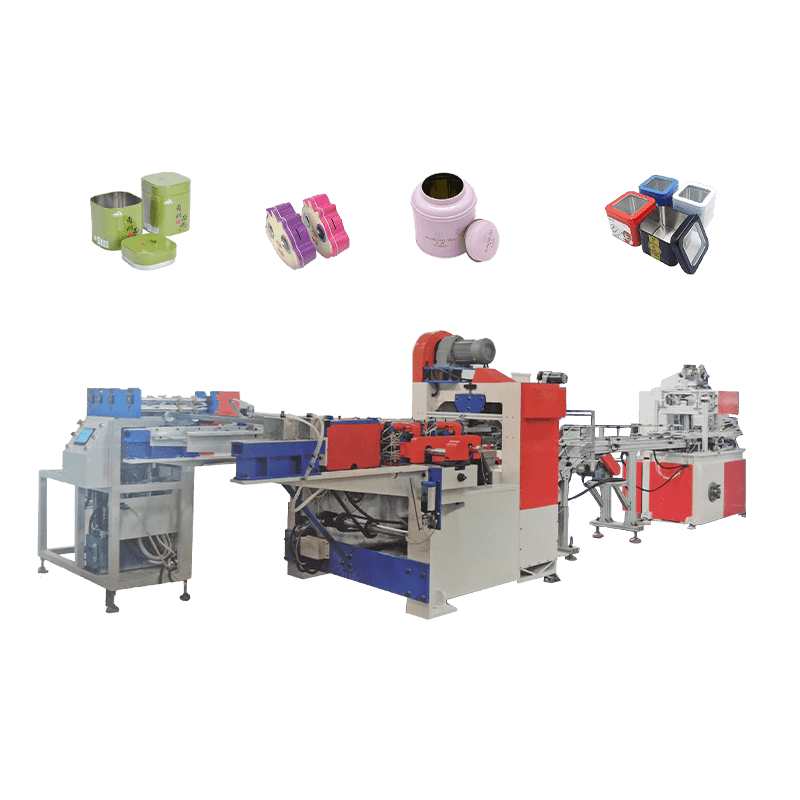

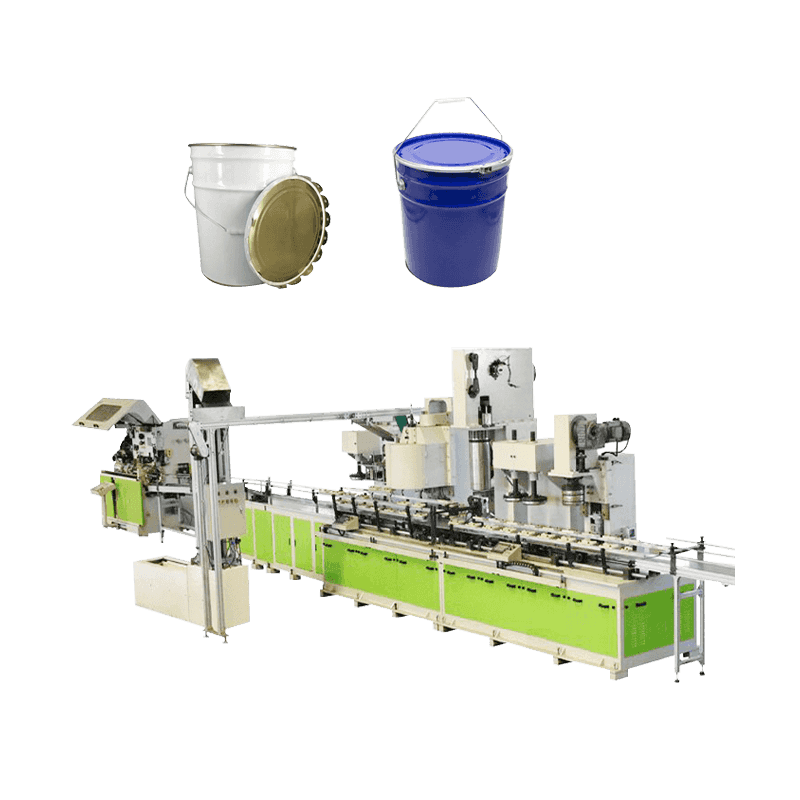

Introduction to Chemical Tin Can Making Machines Chemical tin can making machines are specialized equipment designed to produce tin-plated steel cans used for storing chemicals, solvents, and other in...

READ MORE -

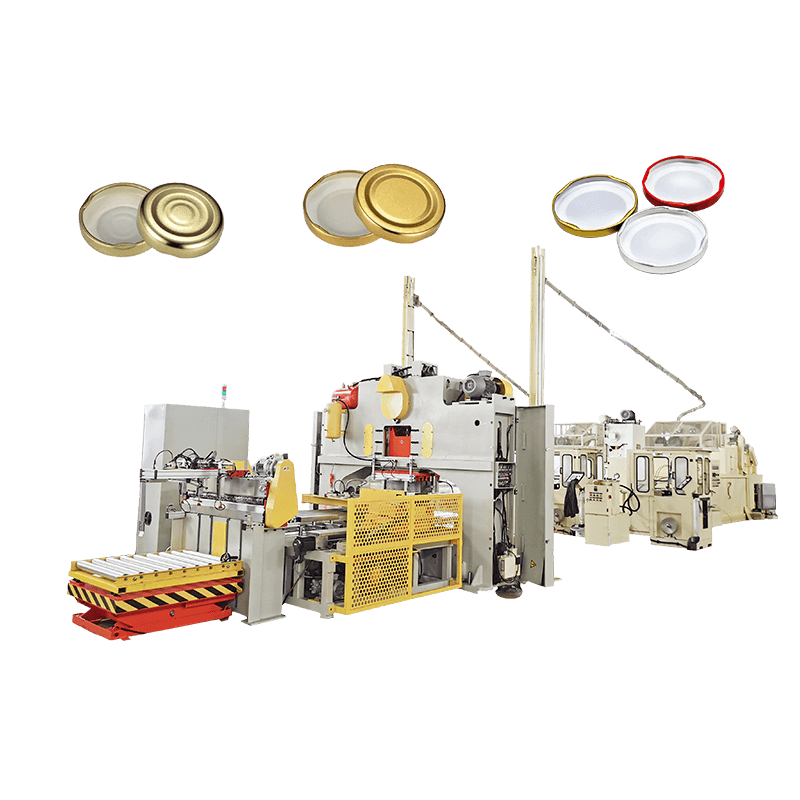

Introduction to Metal Lid Production Lines Metal lid production lines are specialized manufacturing systems used to produce lids for cans, containers, and other packaging applications. These lines int...

READ MORE -

Understanding the 3-Piece Food Tin Can Production Process Before discussing fault diagnosis, it is essential to understand the key stages involved in the production of 3-piece food tin cans. The proce...

READ MORE

Introduction to Rectangular Tin Can Forming Machines: Engineering Excellence in Packaging Technology

Zhoushan Sinda Machinery Co., Ltd., located in Zhoushan, one of China’s primary production bases for metal packaging machinery, is a professional manufacturer and solution provider for metal packing equipment. The company focuses on a complete range of automatic can-making lines and metal lid production machinery, such as Easy Open End (EOE) production lines, 2-piece DRD can lines, food tin can lines, chemical can lines, fancy tin forming systems, aerosol dome and cone lines, metal lid and bottom lines, and duplex slitters. Within this comprehensive portfolio, rectangular tin can forming machines play an essential role in meeting the packaging needs of industries requiring durable, reliable, and uniform metal containers. The following content introduces the engineering principles, structural features, production performance, and application value of rectangular tin can forming machines.

Structural Foundation and Engineering Principles of Forming Machines

Rectangular tin can forming machines are designed to transform flat metal sheets into rectangular containers through a sequence of forming, folding, sealing, and shaping operations. Their engineering design emphasizes mechanical precision, coordinated motion control, and stable output. Zhoushan Sinda Machinery Co., Ltd. integrates advanced manufacturing concepts into these machines by using refined transmission mechanisms, high-precision molds, and durable frame structures. The forming system typically includes sheet feeding, edge folding, body forming, corner shaping, and flanging processes. Each stage is carefully calibrated to maintain dimensional consistency and minimize material deformation. Through controlled pressure distribution and precise mold alignment, the system ensures that the rectangular can body maintains stable geometric characteristics, suitable for industries requiring high-volume packaging consistency.

Production Workflow and Operational Coordination

The workflow of a rectangular tin can forming machine involves a continuous and systematic transformation of metal sheets. The sheet feeding module positions and delivers material smoothly to prevent misalignment during shaping. The forming module bends the sheets into rectangular profiles through dedicated molds, ensuring accurate corner angles and straight edges. After shaping, the machine performs flanging or reinforcing steps to prepare the can body for further operations such as seaming or welding. Zhoushan Sinda Machinery Co., Ltd. enhances machine coordination by integrating electronic monitoring, servo-driven adjustments, and safety interlocks that help maintain smooth operation during long production cycles. The engineering principle focuses on achieving stable output with minimal vibration and mechanical stress to maintain the lifespan of critical components.

Material Compatibility and Forming Adaptability

Rectangular tin can forming machines are compatible with a variety of tinplate thicknesses and coatings required by different packaging sectors. By adjusting mold parameters, clamping pressure, and feeding speed, the machine can adapt to various sheet hardness levels without compromising structure integrity. Zhoushan Sinda Machinery Co., Ltd. designs these systems to work with coated steel sheets, lacquered tinplates, or laminated metal materials commonly used in high-demand packaging environments. This adaptability allows the equipment to serve multiple product lines, including food cans, chemical containers, gift tins, and industrial storage cans. The ability to maintain uniformity across diverse material specifications supports manufacturers seeking flexible production solutions.

| Material Type | Typical Thickness | Application Scope |

|---|---|---|

| Lacquered Tinplate | 0.18–0.28 mm | Food cans and decorative tins |

| Coated Tinplate | 0.20–0.32 mm | Chemical and industrial packaging |

| Laminated Steel Sheets | 0.18–0.30 mm | High-end gift tins |

Automation Design and Production Efficiency

Automation is a core advantage of rectangular tin can forming machines. Systems designed by Zhoushan Sinda Machinery Co., Ltd. incorporate automatic feeding, synchronized forming, and rapid mold switching features that reduce manual intervention. Servo control systems enhance movement precision and allow real-time adjustments during production. The machine’s cycle rate is engineered to support continuous operation, which is essential in high-demand packaging facilities. Automation also reduces material waste by improving cutting accuracy and minimizing forming errors. With stable speed control and electronic diagnostics, operators can quickly identify performance deviations and adjust settings without slowing production flow.

Sealing Precision and Container Integrity

The structural integrity of a rectangular tin can depends on the precision of forming and sealing processes. The machine ensures that corners, flanges, and joints are shaped with uniform thickness and tight fit. Zhoushan Sinda Machinery Co., Ltd. develops molding tools with carefully calibrated clearances to maintain consistent pressure across all forming surfaces. Proper sealing precision prevents leakage in applications such as edible oil containers, paint cans, and solvent packaging. For food-grade applications, the forming equipment can incorporate sanitary design options that limit surface contamination and support strict production standards. The resulting cans exhibit stable stacking performance and durability during transport.

Customization Options and Production Flexibility

Rectangular tin can forming machines can be customized to produce various sizes and structural designs according to market requirements. Zhoushan Sinda Machinery Co., Ltd. offers parameter adjustments for height, width, corner radius, flanging depth, and reinforcement structure. The modular configuration enables quick mold replacement to support multi-size production without lengthy downtime. Manufacturers using multiple packaging formats benefit from this flexibility, especially in sectors such as food processing, household chemical production, and premium gift packaging. This adaptability helps companies respond to changing market needs while maintaining consistent production output.

Quality Control and Monitoring Systems

Maintaining consistent can quality is essential in metal packaging. To support this requirement, rectangular tin can forming machines include sensors, inspection mechanisms, and monitoring software for detecting deviations such as improper folds, uneven edges, or surface damage. Zhoushan Sinda Machinery Co., Ltd. applies quality management technologies that allow real-time detection of thickness variations and shape irregularities. Automated rejection units remove defective cans to maintain an efficient production workflow. By supporting traceability and data recording, the machine helps operators analyze performance patterns and optimize production parameters.

| Inspection Item | Monitoring Method | Purpose |

|---|---|---|

| Edge Fold Accuracy | Optical Sensors | Ensures consistent flanging |

| Corner Angle Precision | Mechanical Gauging | Maintains structural stability |

| Surface Integrity | Camera Inspection | Prevents coating damage |

| Dimensional Accuracy | Digital Measurement Tools | Supports uniform packaging output |

Integration with Complete Production Lines

Rectangular tin can forming machines play a key role when integrated into complete can-making production lines offered by Zhoushan Sinda Machinery Co., Ltd. These machines can be linked with duplex slitters, welding units, beading stations, seaming machines, coating systems, and quality inspection modules. The synchronized operation across multiple stations improves resource utilization and reduces production downtime. Integration also allows manufacturers to establish fully automated packaging plants capable of handling high-volume orders with consistent quality. Through coordinated engineering and system compatibility, the forming machine contributes significantly to the overall efficiency of the can-making workflow.

Efficiency and Production Output of Rectangular Tin Can Forming Machines

Zhoushan Sinda Machinery Co., Ltd. operates in Zhoushan, one of China’s key manufacturing regions for metal packaging machinery. As a professional manufacturer and solution provider, the company develops a wide range of equipment, including Easy Open End (EOE) production lines, 2-piece DRD can lines, food tin can lines, chemical can lines, fancy tin can lines, aerosol dome and cone lines, metal lids and bottom lines, and duplex slitters. Among these advanced systems, rectangular tin can forming machines play an essential role in supporting efficient and stable can production. Their engineering design, automated operation, and coordinated system integration significantly influence the overall productivity of modern can-making factories. This article discusses the efficiency characteristics and production output performance of these machines.

Core Operating Principles Supporting Efficient Production

The efficiency of a rectangular tin can forming machine is determined by its mechanical precision, stable transmission system, and coordinated forming steps. The machine typically consists of sheet feeding units, shaping mechanisms, corner-forming modules, and flanging systems. Zhoushan Sinda Machinery Co., Ltd. enhances each stage using refined manufacturing techniques that emphasize consistent motion control and reliable mechanical engagement. As the metal sheet enters the forming area, synchronized components ensure smooth bending and accurate shaping to reduce misalignment. The operation relies on steady pressure distribution and properly configured mold structures, allowing the machine to maintain a continuous output during extended production cycles. Through these engineering principles, the equipment supports high operational efficiency while preserving structural accuracy.

Automated Feeding and Continuous Production Flow

One of the major factors influencing production output is the machine’s ability to sustain continuous material feeding. The automated sheet feeding system minimizes interruptions and reduces manual involvement, allowing the forming machine to operate at a consistent pace. Zhoushan Sinda Machinery Co., Ltd. integrates servo-driven technologies into the feeding module to regulate speed, ensure proper tension, and maintain sheet positioning before entering the forming zone. This coordination is essential in preventing production slowdowns caused by feeding errors. The continuous workflow supports factories requiring stable and predictable hourly output, which is vital for industries producing food containers, household chemicals packaging, and decorative tins.

Speed Capabilities and Output Range

The production output of rectangular tin can forming machines varies depending on the model, configuration, and material thickness. Zhoushan Sinda Machinery Co., Ltd. develops equipment designed for both medium- and high-speed applications, catering to different operational needs. Machines operating at higher cycle speeds can achieve a steady flow of rectangular can bodies while maintaining dimensional consistency. The production capacity also depends on how efficiently the forming, folding, and flanging processes are synchronized. By supporting adjustable speeds, the machine allows manufacturers to match production output with demand, improving overall resource allocation.

| Machine Category | Typical Cycle Speed | Expected Output |

|---|---|---|

| Standard Forming Machine | 20–40 cans/min | Suitable for medium-scale production |

| High-Speed Forming Machine | 40–70 cans/min | Supports large-volume manufacturing |

| Customized Heavy-Duty Model | Variable, depending on configuration | Used for specialized industrial applications |

Energy Utilization and Operational Stability

Operational stability contributes directly to production efficiency. A machine that maintains consistent mechanical movement without frequent stops or vibrations helps sustain higher output levels. Zhoushan Sinda Machinery Co., Ltd. focuses on building machines with balanced transmission systems, reinforced structural frames, and precision bearings to reduce energy loss during forming operations. Stable energy utilization also lowers operational costs, allowing manufacturers to achieve long-term productivity without excessive electricity consumption. The machine’s monitoring systems help operators track performance indicators, identify inefficiencies, and make adjustments in real time to maintain steady output.

Forming Accuracy and Its Impact on Production Output

Rectangular tin can forming machines require high forming accuracy to ensure that the can body meets dimensional requirements. When shaping precision is stable, downstream equipment—such as welding units, beading machines, and seaming systems—can operate without interruptions. Zhoushan Sinda Machinery Co., Ltd. designs molds and forming components to maintain consistent edge folding, corner shape accuracy, and surface smoothness. High forming accuracy reduces the number of rejected cans, which directly improves production efficiency. With fewer production errors, the overall output remains predictable, supporting factories that need continuous and uniform manufacturing performance.

Integration with Upstream and Downstream Equipment

The efficiency of a rectangular tin can forming machine is also influenced by how well it integrates with other equipment in a full production line. Zhoushan Sinda Machinery Co., Ltd. specializes in creating complete can-making solutions where forming machines are designed to work seamlessly with duplex slitters, body welding lines, coating units, and metal lid production systems. Smooth integration reduces bottlenecks and supports consistent material flow. When machines operate cohesively, the production line achieves higher operational efficiency and minimizes idle time between processes. This level of integration is especially beneficial for large-scale metal packaging manufacturers aiming to streamline production from sheet cutting to final can assembly.

Machine Durability and Its Role in Long-Term Output Performance

Durability influences productivity because machines that maintain performance over long periods allow manufacturers to plan for extended production cycles without frequent maintenance interruptions. Zhoushan Sinda Machinery Co., Ltd. constructs rectangular tin can forming machines using high-strength components and wear-resistant parts to withstand continuous operation. The longevity of forming molds, rollers, and guiding systems contributes to more predictable output over time. Reduced downtime means factories can utilize their production capacity more effectively, manage labor scheduling more efficiently, and fulfill orders with greater consistency.

Quality Monitoring and Output Optimization

Quality monitoring enhances output efficiency by reducing material waste and minimizing defective products. Modern rectangular tin can forming machines from Zhoushan Sinda Machinery Co., Ltd. incorporate sensors, vision systems, and digital monitoring software that identify misalignment, thickness variation, or improper folding in real time. Early detection allows operators to adjust the forming parameters before issues escalate, preserving both output quantity and material usage. This monitoring capability ensures that production remains stable across long shifts, supporting a balanced relationship between speed and quality.

| Monitoring Feature | Function | Impact on Output |

|---|---|---|

| Optical Sensors | Detect edge folding accuracy | Reduces rework and maintains forming consistency |

| Camera Inspection Systems | Monitor surface conditions | Prevents defective cans from entering the next stage |

| Digital Performance Tracking | Records operational data | Helps optimize speed and parameter settings |

Adaptability to Different Product Specifications

Rectangular tin can forming machines often support multiple can sizes and structural designs, enhancing production flexibility. Zhoushan Sinda Machinery Co., Ltd. designs its machines with adjustable parameters, allowing rapid mold changeovers to minimize downtime. This adaptability helps manufacturers switch between products without significantly affecting output efficiency. Factories serving food, chemical, or promotional gift packaging industries can maintain steady production while meeting diverse market requirements. The adjustable configuration ensures that output remains consistent even when handling different material thicknesses or sizes.

English

English عربى

عربى русский

русский