Tin Can Making Machines – Parameter Table

| Parameter Category | Typical Parameter Details |

|---|---|

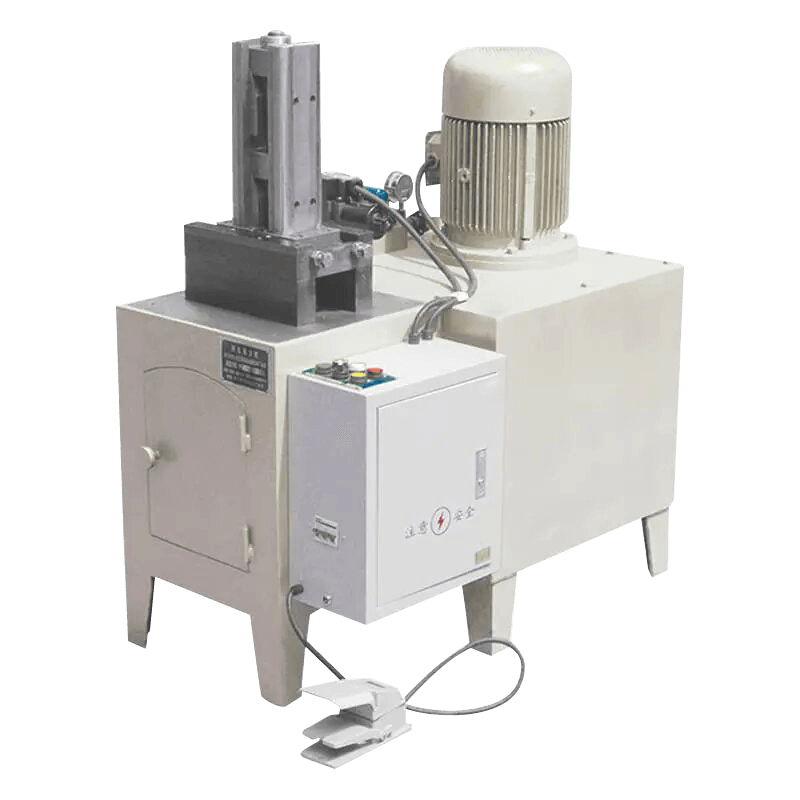

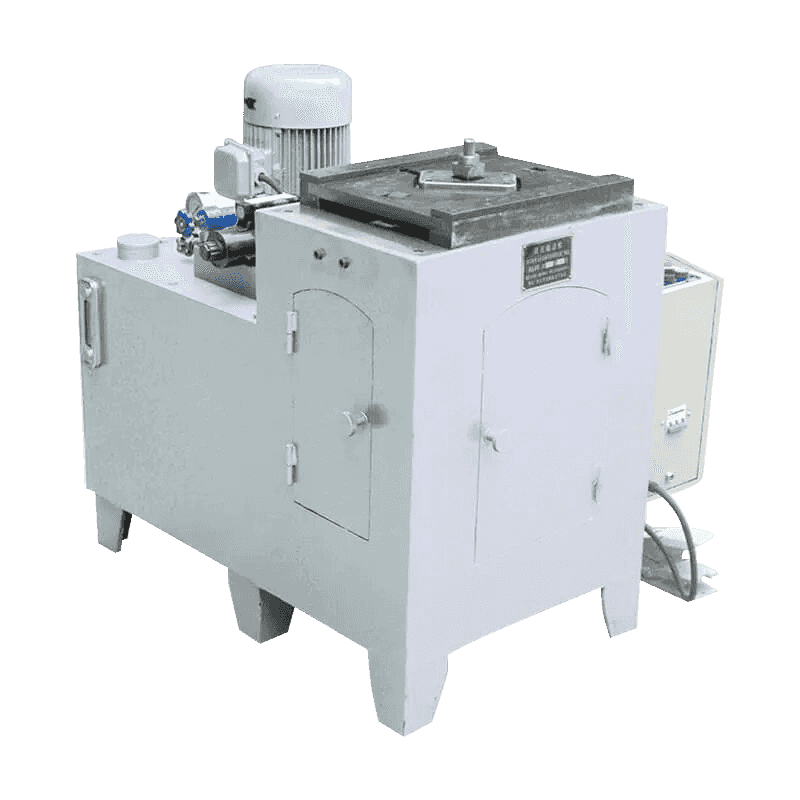

| Equipment Type | Fully automatic / semi-automatic 3-piece can line, 2-piece can line, metal lid production line, welder, flanging machine, necking machine, leakage tester, etc. |

| Applicable Materials | Tinplate, aluminum sheet, coated steel |

| Material Thickness Range | 0.18–0.40 mm (customizable) |

| Applicable Can Types | Round cans, square cans, irregular-shaped cans, food cans, paint cans, chemical cans, beverage cans, etc. |

| Can Diameter Range | Φ 52–400 mm (depending on model) |

| Can Height Range | 50–600 mm (adjustable) |

| Air Supply Requirements | 0.6–0.8 MPa, dry and stable compressed air |

| Control System | PLC automatic control system (e.g., Siemens / Mitsubishi) with touch-screen HMI |

| Automation Features | Automatic feeding, automatic welding monitoring, visual inspection, automatic leakage detection, automatic stacking, etc. |

| Safety Protection | Overload protection, emergency stop button, safety guards, fault alarm system |

| Applicable Industries | Food packaging, beverage packaging, chemical packaging, paint and coating industry, industrial metal container manufacturing |

| Service Life | 10–15 years (depending on maintenance) |

| Customization Options | Can size, speed level, automation level, LOGO customization, non-standard production line design |

Application

Food Packaging Industry

Used for producing various food cans, including meat cans, coffee cans, biscuit tins, and canned fruit containers.

Beverage Packaging

Suitable for manufacturing beverage cans such as tea drinks, coffee beverages, and functional drink metal containers.

Chemical & Paint Containers

Applied in the production of chemical cans, paint buckets, and solvent containers requiring durable and corrosion-resistant metal packaging.

Aerosol Cans

Used to manufacture aerosol containers such as air freshener cans, insecticide cans, and personal care spray cans.

Oil & Lubricant Packaging

Suitable for producing metal containers for engine oil, lubricants, and related industrial liquids.

General Industrial Metal Containers

Capable of producing hardware packaging cans, tool cans, and various industrial accessory containers.

Advantage

High Efficiency

Can produce up to 300 pcs/min, meeting the needs of large-scale and continuous production.

Flexible Can Size Adjustment

Allows quick changeover for various diameters and heights, improving overall production flexibility.

Advanced Automation System

Features PLC control, touch-screen HMI, and automated feeding, welding monitoring, leak testing, and stacking.

Energy-Saving & Low Maintenance

Designed with optimized mechanical structures to reduce power consumption and minimize maintenance needs.

High Precision Forming

Ensures accurate forming, flanging, beading, and seaming to maintain stable dimensional accuracy.

Enhanced Safety Protection

Includes overload protection, emergency stop buttons, safety covers, and fault alarm systems for operator safety.

Durable Structure

Built with high-strength frames and long-life components to ensure reliable performance during long-term operation.

Customizable Configuration

Speed, can size, automation level, and optional modules can be customized to meet different industry requirements.

English

English عربى

عربى русский

русский