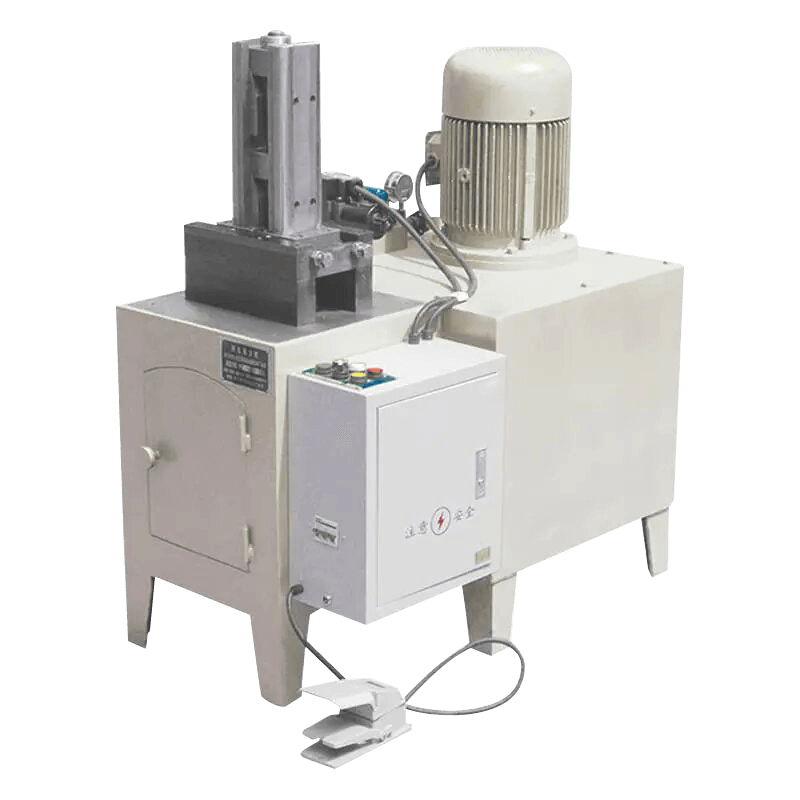

Specification

| Parameter Category | Specification Content | Remarks / Additional Information |

|---|---|---|

| Production Capacity | 1,000–60,000 cans/hour | Depends on can type |

| Can Types | Round, Square, Fancy, 3-Piece | Multiple industry support |

| Material | Tinplate, Aluminum, Steel | Thickness 0.18–0.30 mm |

| Automation Level | Fully Automatic / Semi-Automatic | Flexible configuration |

| Control System | PLC + HMI | Monitors production in real time |

| Power Requirement | 380V/50Hz | Adjustable |

| Tooling Options | Interchangeable Dies | Supports different can sizes |

| Machine Footprint | 20–50 m² | Depends on layout |

| Quality Compliance | ISO9001, CE | International standards |

| Optional Features | Printing, Labeling, Embossing | Enhances product appearance |

| Maintenance | Preventive maintenance schedule | Ensures reliability |

| Safety Features | Emergency stop, Overload protection | CE certified |

| Application | Food, Beverage, Chemical | Industrial production lines |

Application

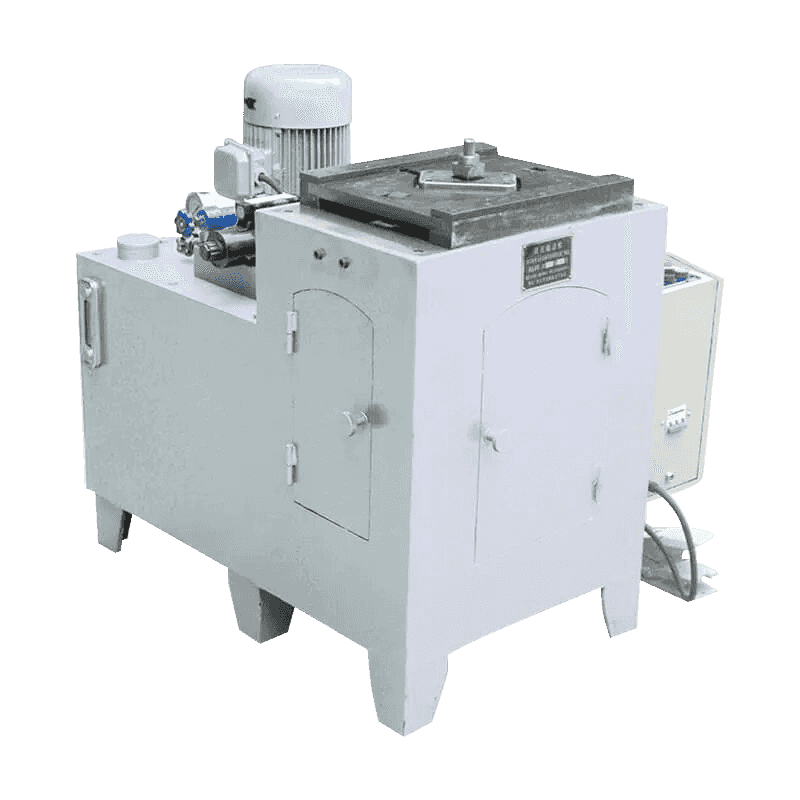

Integrated Production

Provides complete solutions for can manufacturing, including body forming, end making, and sealing, suitable for food, beverage, and industrial sectors.

Flexible Manufacturing

Allows customization of machinery for producing different can types, sizes, and materials, supporting a variety of production needs.

Industrial Efficiency

Used in factories to streamline can production processes, improve output, and maintain consistent quality across all production stages.

Advantage

Integrated Solution

Combines multiple stages of can production including body forming, end making, and sealing, providing a streamlined and coordinated workflow.

Flexible Configuration

Can be customized to produce different can types and sizes, allowing manufacturers to meet diverse production demands.

Reliable Performance

Engineered for stable operation with precise control, ensuring consistent quality and reducing the risk of defects.

English

English عربى

عربى русский

русский