Specification

| Parameter Category | Specification Content | Remarks / Additional Information |

|---|---|---|

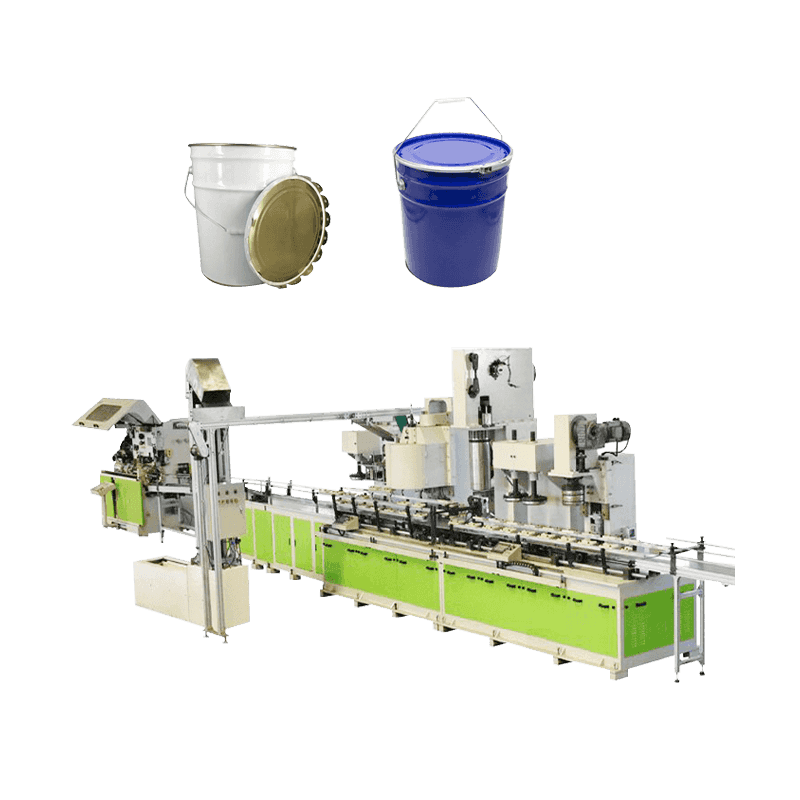

| Production Capacity | 1,000–25,000 cans/hour | Varies with can size and wall thickness |

| Can Types | Round, Square, Specialty | Suitable for chemical and industrial packaging |

| Material | Steel, Tinplate | Corrosion-resistant options available |

| Automation Level | Semi-Automatic / Fully Automatic | Optional integration with filling lines |

| Control System | PLC with HMI | Real-time monitoring and automatic adjustments |

| Power Requirement | 380V/50Hz | Customizable per client country |

| Safety Features | Emergency stop, overload protection | Ensures operator safety and process reliability |

| Footprint | 15–45 m² | Modular design for space optimization |

| Compliance | ISO9001, CE, CB | International industrial and chemical packaging standards |

Application

Paints and Coatings

Manufactures metal cans for storing paints, varnishes, and industrial coatings, ensuring airtight closure and protection from contamination.

Adhesives and Sealants

Used for packaging adhesives, sealants, and lubricants in tin cans, supporting precise filling and secure sealing for industrial use.

Petrochemical Products

Applicable for cans used in oils, greases, and other chemical products, providing corrosion resistance and durable storage solutions.

Advantage

Durable Construction

Designed to produce cans resistant to corrosion and chemical reactions, suitable for storing paints, adhesives, and industrial chemicals.

Reliable Sealing

Ensures airtight and leak-proof sealing, preventing contamination and maintaining chemical integrity.

High Efficiency

Capable of continuous production for industrial-scale chemical packaging, optimizing manufacturing processes.

English

English عربى

عربى русский

русский