Specification

| Parameter Category | Specification Content | Remarks / Additional Information |

|---|---|---|

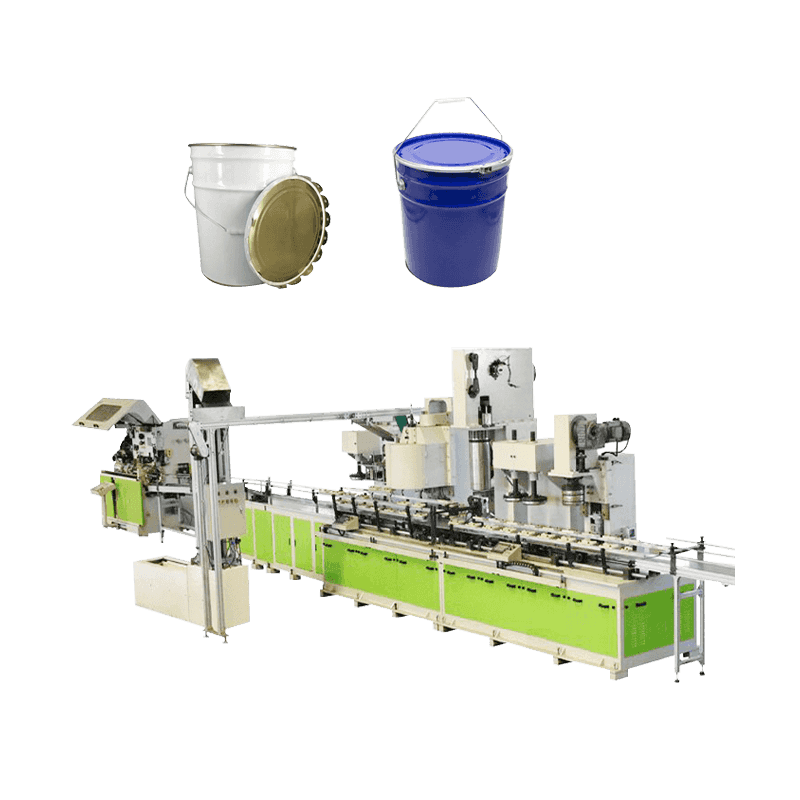

| Production Capacity | 1,500–30,000 cans/hour | Varies with diameter and height |

| Can Shape | Round | Food, Beverage, Industrial |

| Material | Tinplate, Aluminum, Steel | Thickness 0.18–0.30 mm |

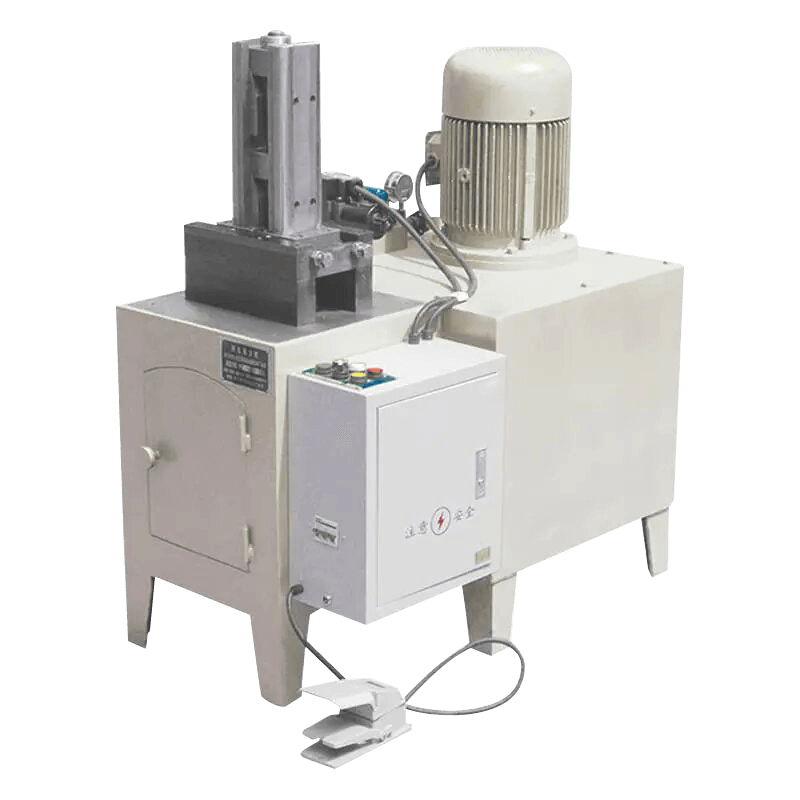

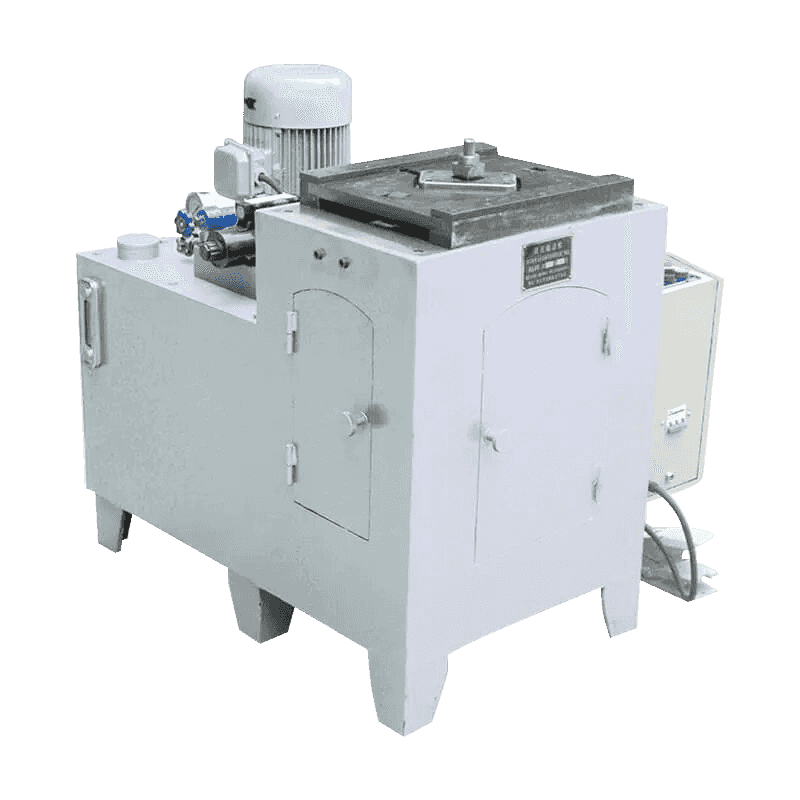

| Automation Level | Semi-Automatic / Fully Automatic | Includes forming, seaming, printing |

| Control System | PLC + HMI | Full monitoring and alarms |

| Power Requirement | 380V/50Hz | Customizable |

| Tooling Options | Interchangeable dies | For different diameters |

| Machine Footprint | 12–40 m² | Depends on configuration |

| Quality Compliance | ISO9001, CE | International standard |

| Optional Features | Labeling, Embossing | Branding customization |

| Maintenance | Preventive maintenance schedule | Ensures reliability |

| Safety Features | Emergency stop, overload protection | Complies with CE |

| Application | Food, Beverage, Industrial | Multiple industries supported |

Application

Food Packaging

Designed to produce round cans for soups, vegetables, fruits, seafood, and dairy products, offering convenient storage and handling.

Cosmetic Products

Used for packaging creams, balms, and specialty cosmetics in round tins with professional finishing for retail markets.

Beverage Industry

Applicable for round beverage cans, ensuring smooth surfaces and uniform shapes suitable for labeling and branding.

Advantage

Uniform Shape

Produces perfectly round cans, ensuring smooth labeling, stacking, and easy handling for food and beverage products.

High Efficiency

Optimized for large-scale production with minimal downtime, increasing throughput for round can packaging.

Material Flexibility

Can process various metals including tinplate and aluminum, supporting different application needs.

English

English عربى

عربى русский

русский