Specification

| Parameter Category | Specification Content | Remarks / Additional Information |

|---|---|---|

| Production Capacity | 500–10,000 cans/hour | Depends on can type and operator skill |

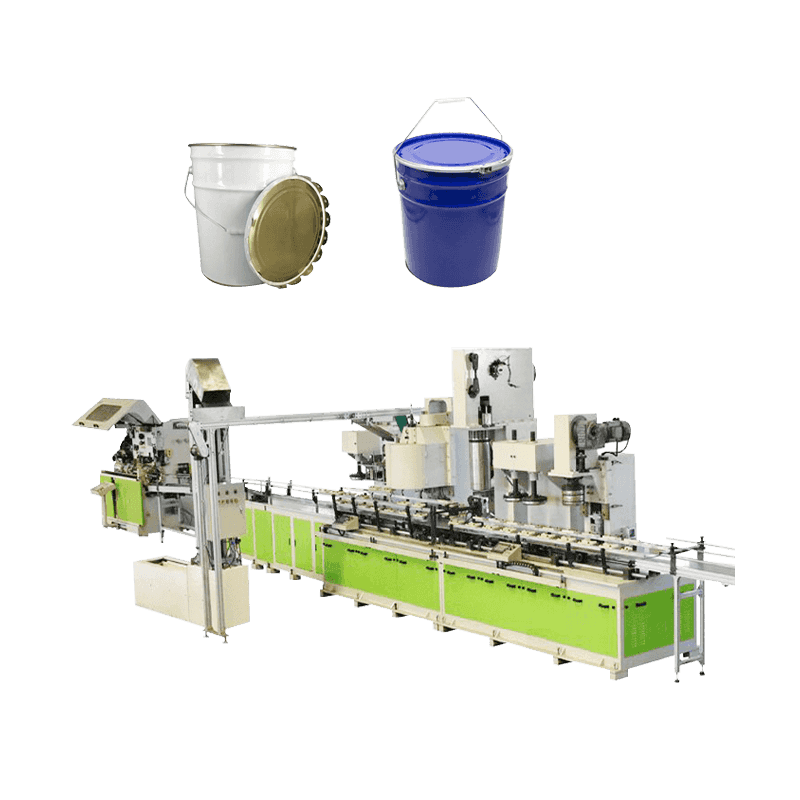

| Can Types | Round, Square, 3-Piece | Food, beverage, industrial cans |

| Material | Tinplate, Aluminum | Thickness 0.18–0.30 mm |

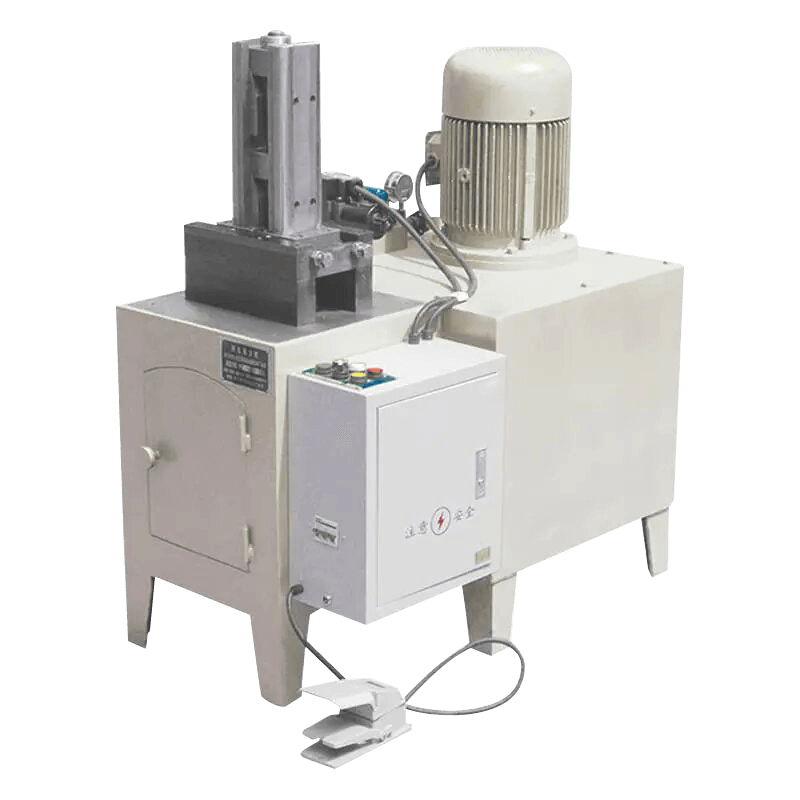

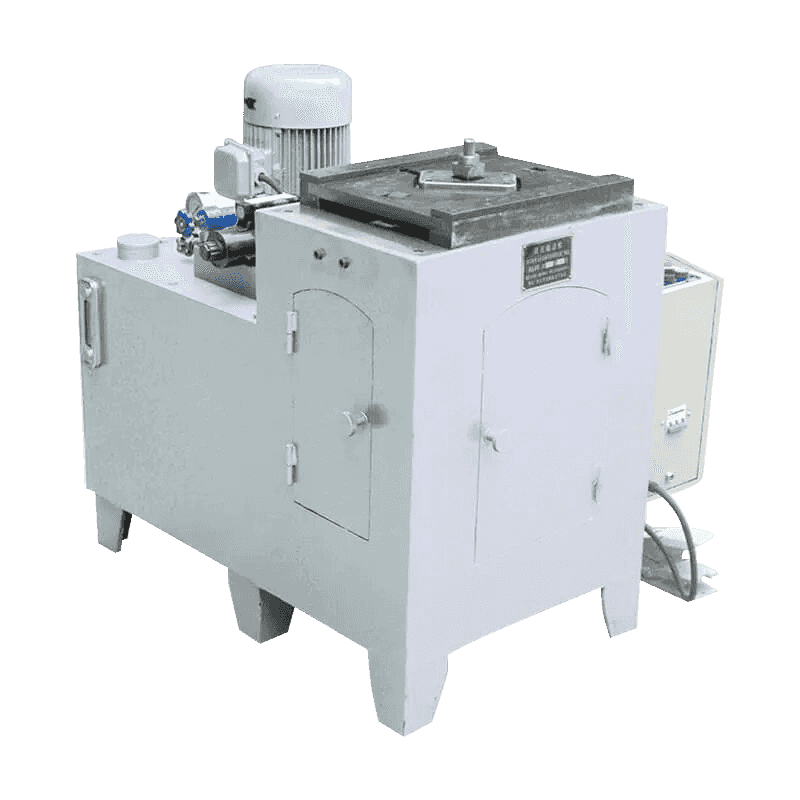

| Automation Level | Semi-Automatic | Requires partial manual operation |

| Control System | PLC + HMI | Monitors essential functions |

| Power Requirement | 380V/50Hz | Customizable |

| Tooling Options | Interchangeable Dies | Supports multiple can sizes |

| Machine Footprint | 15–45 m² | Depends on line layout |

| Quality Compliance | ISO9001, CE | Meets international standards |

| Optional Features | Printing, Labeling | Enhances product branding |

| Maintenance | Preventive maintenance schedule | Ensures reliability |

| Safety Features | Emergency stop, Overload protection | CE certified |

| Application | Food, Beverage, Chemical | Supports multiple industries |

Application

Small to Medium Food Production

Suitable for small to medium-scale canned food manufacturing, combining automation with manual operation for flexible production.

Specialty Beverages

Used for semi-automatic production of beverage cans in smaller batches, suitable for craft drinks or seasonal products.

Custom or Limited Industrial Production

Applied to chemical or specialty industrial cans where moderate automation is sufficient, providing balance between efficiency and cost.

Advantage

Flexible Operation

Combines automation with manual control, allowing customization for small and medium-scale production runs.

Cost Efficiency

Lower initial investment compared to fully automatic lines while maintaining reliable production performance.

Adaptable Production

Can be adjusted to handle different can types, sizes, and materials, providing versatile manufacturing options.

English

English عربى

عربى русский

русский