Specification

| Parameter Category | Specification Content | Remarks / Additional Information |

|---|---|---|

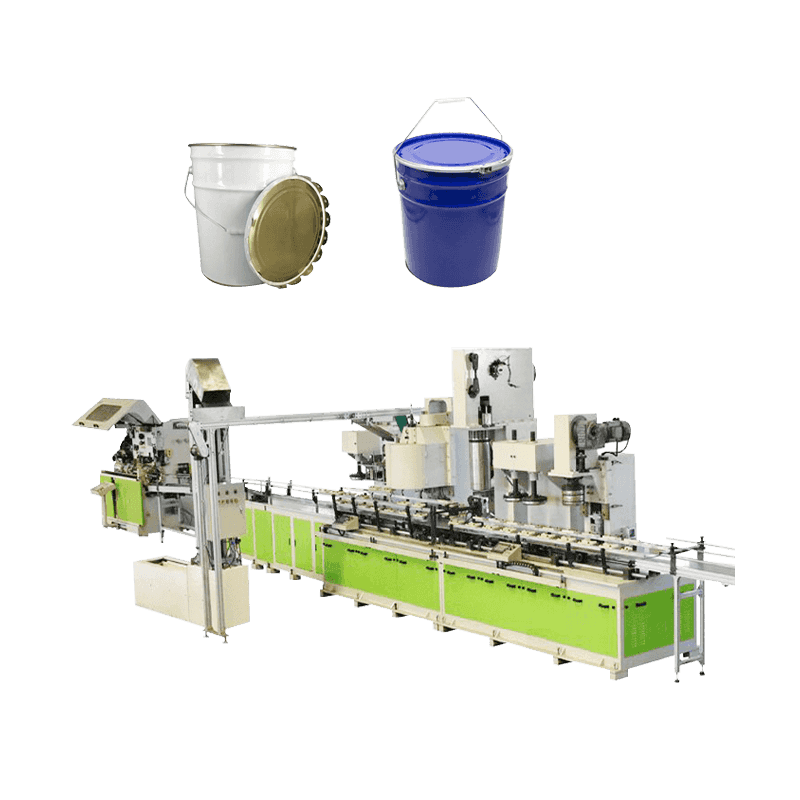

| Production Capacity | 2,000–35,000 cans/hour | High-speed automatic operations |

| Can Type | 2-piece, 3-piece, Round, Square | Suitable for food and beverage |

| Automation Level | Fully Automatic | Includes feeding, forming, seaming |

| Power Requirement | 380V/50Hz | Customized for local standards |

| Control System | PLC + Touch Screen HMI | Real-time monitoring and error detection |

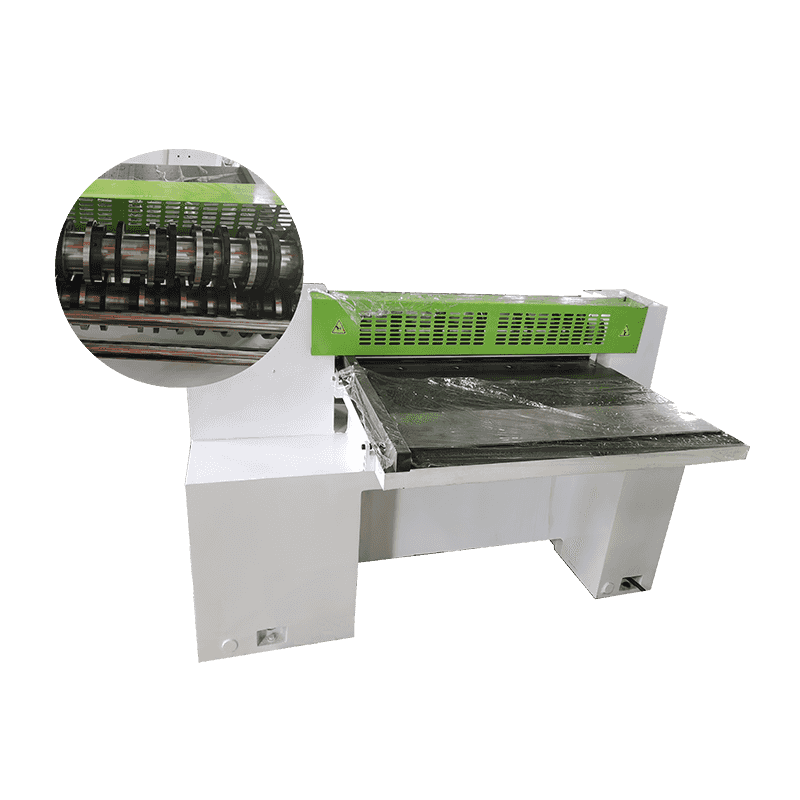

| Material Compatibility | Tinplate, Aluminum | Thickness range 0.18–0.30 mm |

| Safety Features | Emergency stop, overload protection | Meets international safety standards |

| Machine Footprint | 15–45 m² | Depends on configuration |

| Compliance | ISO9001, CE | International quality and safety certification |

Application

High-Volume Food Production

Designed for automated production of food cans at large scale, including soups, sauces, and ready meals, improving efficiency and reducing manual labor.

Beverage Industry

Ideal for producing soda, juice, and energy drink cans with uniform shape and precise sealing, suitable for large-scale beverage manufacturers.

Industrial Packaging

Used for automatically manufacturing cans for chemicals, paints, and oils, ensuring precise filling, sealing, and high-speed production capabilities.

Advantage

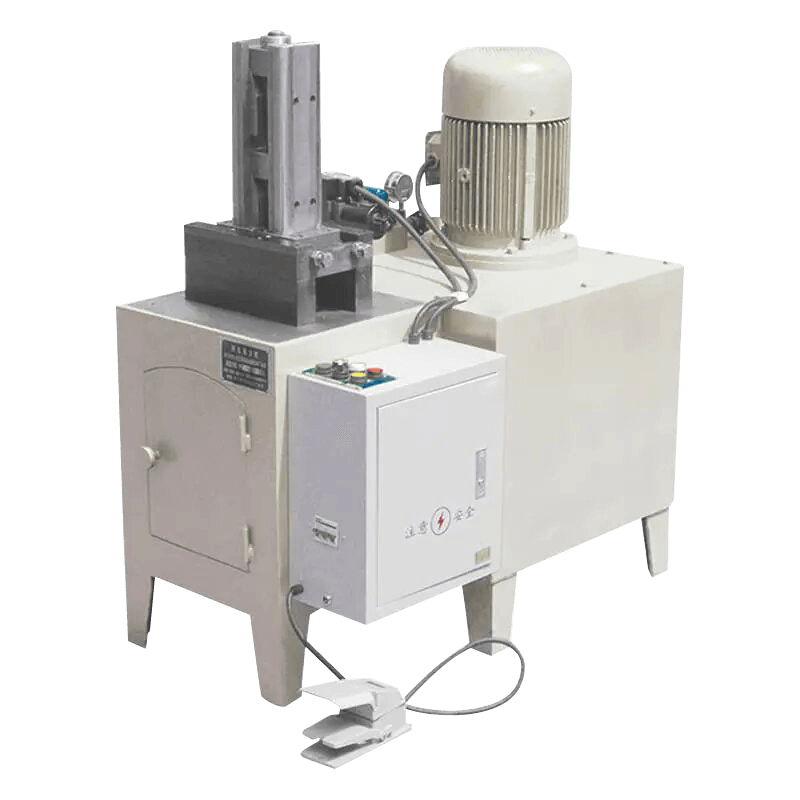

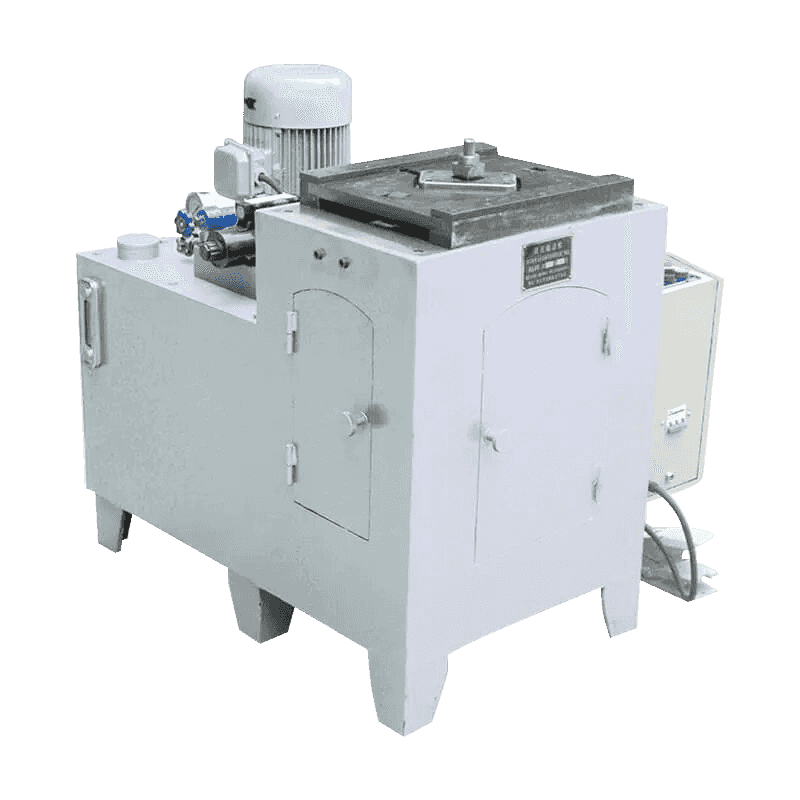

Fully Automated Operation

Reduces manual intervention by automating body forming, end making, and sealing, increasing production consistency and efficiency.

High-Speed Performance

Capable of producing large volumes of cans quickly, meeting the needs of high-demand food and beverage industries.

Precision and Reliability

Ensures accurate can dimensions and secure sealing, minimizing leakage and maintaining product integrity.

English

English عربى

عربى русский

русский