Specification

| Parameter Category | Specification Content | Remarks / Additional Information |

|---|---|---|

| Production Capacity | 5,000–50,000 cans/hour | Depends on can type |

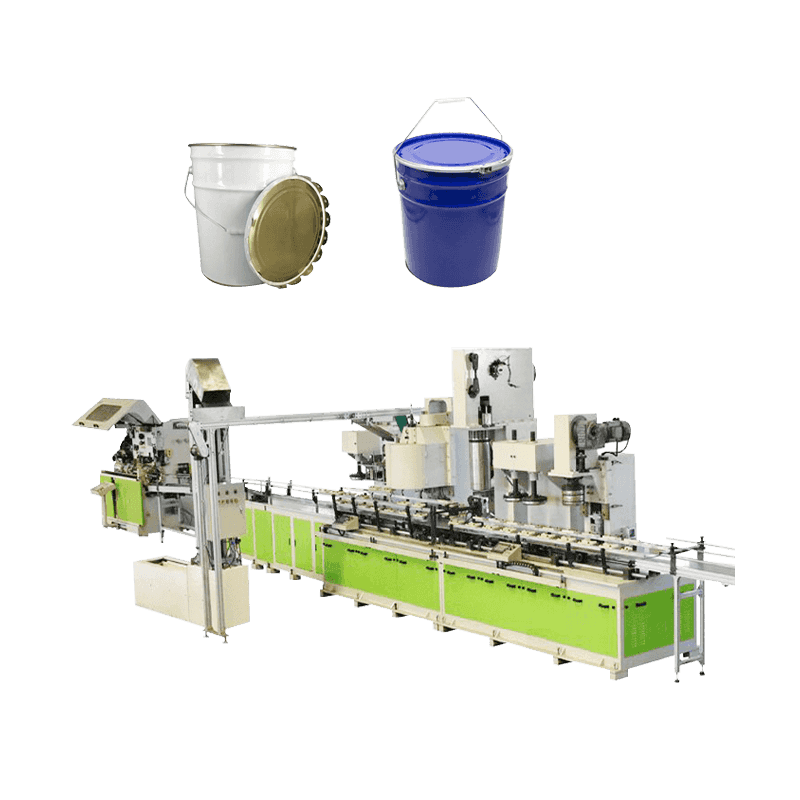

| Can Types | Round, Square, Fancy, 3-Piece | Supports food, beverage, chemical cans |

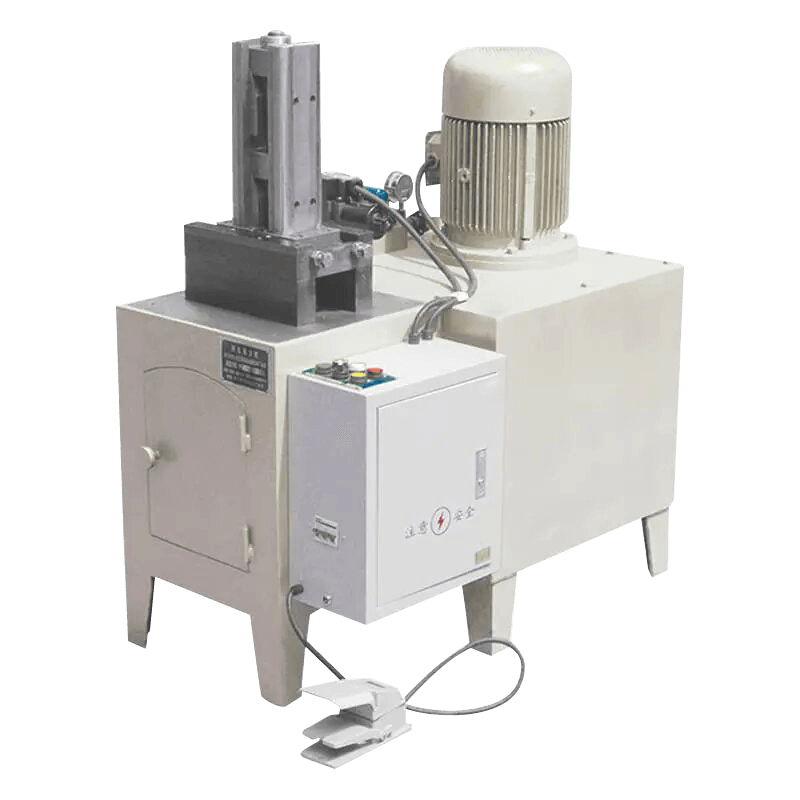

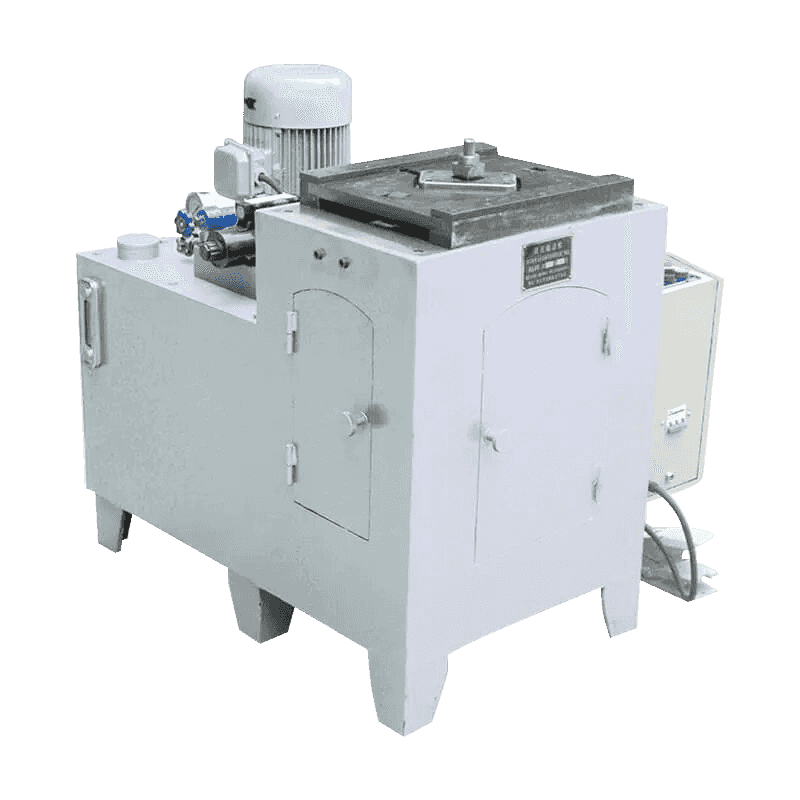

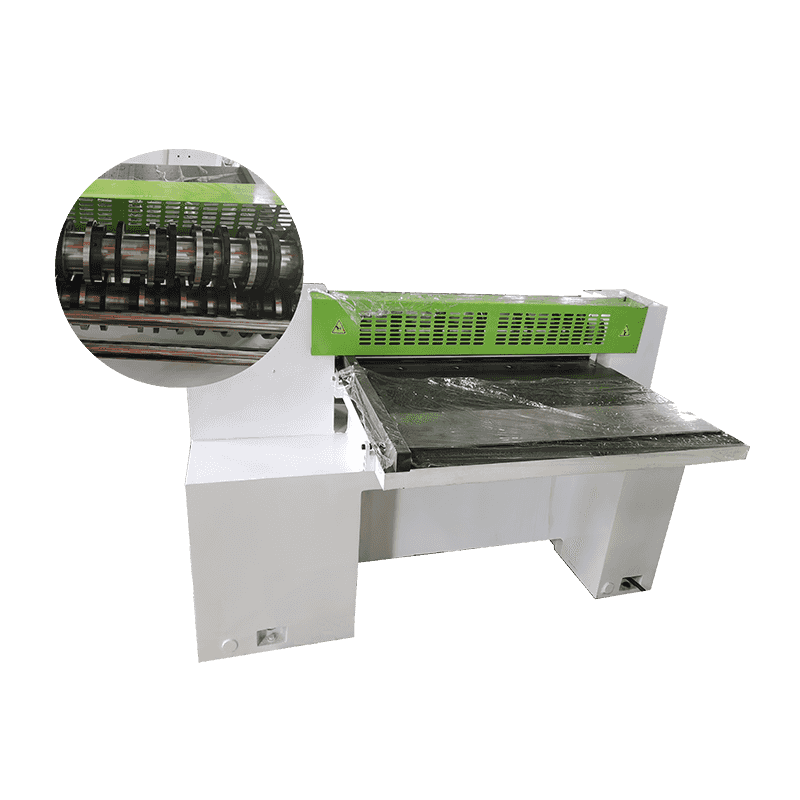

| Material | Tinplate, Aluminum, Steel | Thickness 0.18–0.30 mm |

| Automation Level | Fully Automatic | Minimal manual intervention |

| Control System | PLC + HMI | Full process monitoring |

| Power Requirement | 380V/50Hz | Customizable per line |

| Tooling Options | Interchangeable Dies | Supports multiple can sizes |

| Machine Footprint | 20–60 m² | Depends on configuration |

| Quality Compliance | ISO9001, CE | International standard |

| Optional Features | Printing, Embossing, Labeling | Branding enhancements |

| Maintenance | Preventive maintenance schedule | Ensures smooth operation |

| Safety Features | Emergency stop, Overload protection | CE certified |

| Application | Food, Beverage, Chemical, Industrial | Supports high-volume production |

Application

Large-Scale Food Manufacturing

Enables fully automated production of canned food products, minimizing manual labor and ensuring consistent quality across batches.

Beverage Production

Used for fully automated beverage can production, including filling, sealing, and labeling, suitable for high-volume factories.

Industrial Cans

Applied to chemical, oil, and paint cans requiring fully automated production for efficiency, precision, and reliable sealing.

Advantage

End-to-End Automation

Handles can body forming, end making, filling, and sealing automatically, minimizing manual intervention and error.

High Consistency

Ensures uniform can quality and precise sealing across production batches.

Labor Cost Reduction

Reduces workforce requirements while maintaining high output, suitable for large-scale operations.

English

English عربى

عربى русский

русский