Specification

| Item | Specification | Remarks |

|---|---|---|

| Production Capacity | 30,000–120,000 cans/hour | Adjustable based on customer requirements |

| Raw Materials | Tinplate, Aluminum | Supports various thicknesses and types |

| Material Thickness | 0.18–0.35 mm | Suitable for different food and beverage cans |

| Can End Diameter | 200–310 mm | Mold can be adjusted for different applications |

| Pull Tab Type | Standard / Custom | Configurable according to product needs |

| Blanking Unit | High-precision tooling | Ensures uniform lid dimensions |

| Drawing & Forming | 1–3 drawing stages | Designed based on lid height and shape |

| Curling / Scoring | High-precision curling and scoring | Improves compatibility for downstream seaming |

| Coating / Curing | Food-grade coating | Balanced temperature control for corrosion resistance |

| Tab Riveting | Automatic riveting | Supports online inspection and adjustment |

| Inspection System | Visual inspection system | Detects surface scratches, dimensional deviations, and tab quality |

| Automation Level | PLC control + HMI interface | Supports data monitoring and alarms |

| Power Requirement | 80–150 kW | Depends on configuration and production capacity |

| Floor Space | 25–60 m² | Varies with line configuration and module count |

| Environmental Requirements | Temperature 18–28℃, Humidity 40–70% | Recommended with ventilation and temperature control system |

| Expandability | Supports multiple product sizes | Additional smart modules or auxiliary equipment can be added |

| After-Sales Service | Line installation, commissioning, training, and technical support | Complete solutions provided |

Application

Food Industry Applications

Easy open-end can lines are widely used in the food industry to produce various canned products such as fruits, vegetables, canned meats, and ready-to-eat meals. Through precise blanking, drawing, curling, and tab riveting processes, the produced easy-open metal ends maintain good sealing performance and structural stability while providing consumers with convenient opening. This automated production method enhances throughput and packaging consistency, meeting both food safety and storage requirements.

Beverage Industry Applications

In the beverage sector, including carbonated drinks, fruit juices, and functional beverages, easy-open metal cans are a primary packaging form. Easy open-end can lines ensure that lids remain pressure-resistant and leak-proof during sealing, while offering smooth and user-friendly opening. Automation and online quality inspection throughout the line ensure that each can maintains stable sealing performance and ease of opening, even at high production speeds, meeting the dual requirements of efficiency and quality in modern beverage packaging.

Multi-Specification and Multi-Material Adaptability

Modern easy open-end can lines are highly adaptable, capable of processing tinplate, aluminum, and other materials, while producing products in a wide range of sizes. This versatility allows application across the food, beverage, pet food, chemical, and consumer goods industries, fulfilling diverse market demands and enhancing the investment value and operational efficiency of the production line.

Advantage

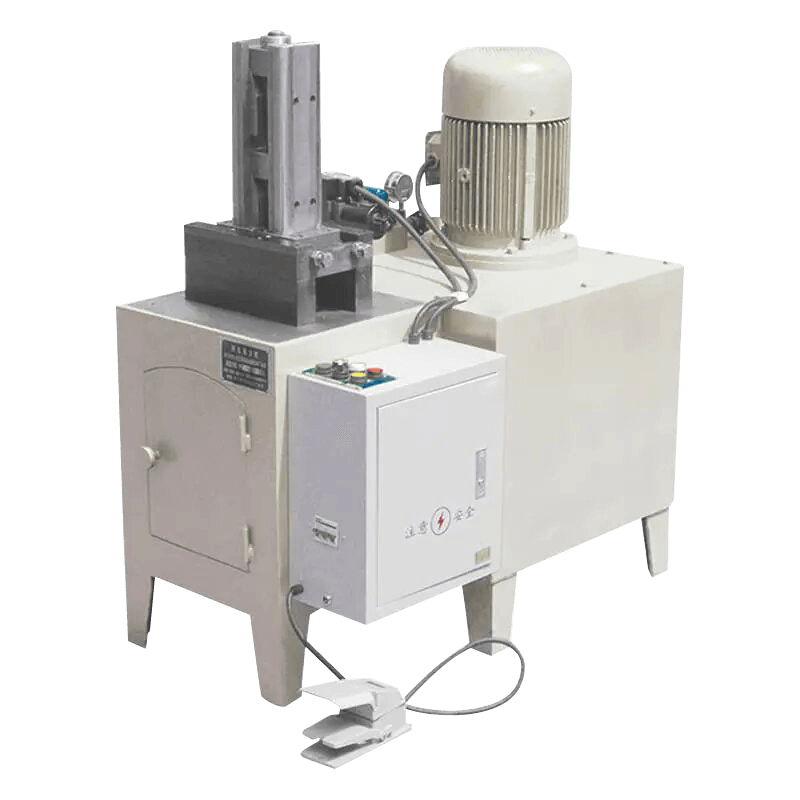

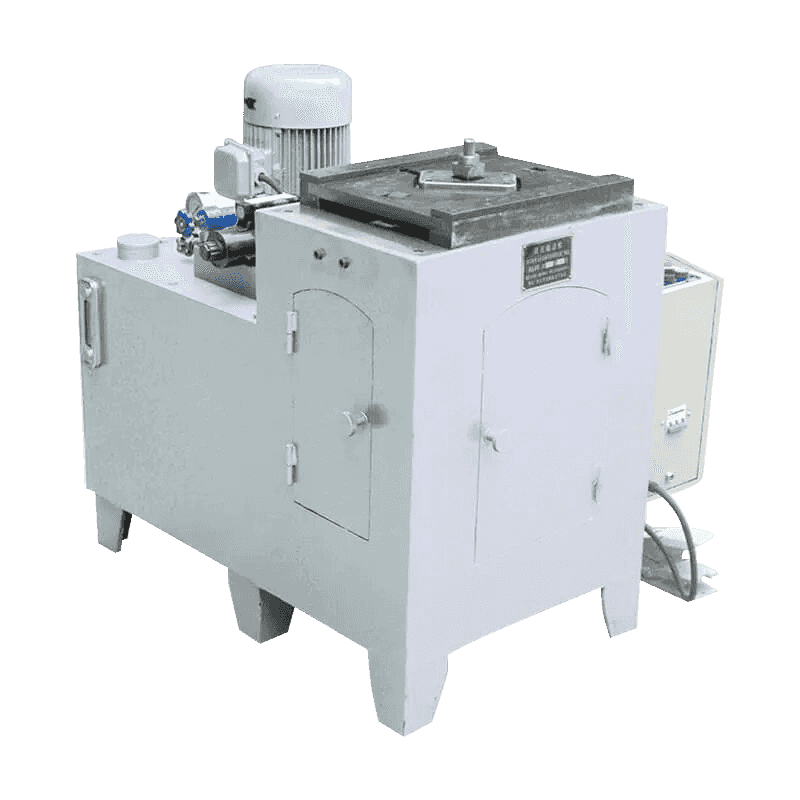

Compact Structure

Easy open-end can lines are designed with a compact layout, minimizing floor space while arranging functional units efficiently to enable continuous processing from raw material to finished product. The compact structure not only saves factory space but also facilitates installation and adjustments, allowing high-efficiency production even in limited plant areas.

High Automation

The production line features PLC control and HMI operation interface, equipped with automatic feeding, blanking, drawing, curling, tab riveting, and online inspection functions to achieve full-process automation. High automation reduces manual intervention, improves production efficiency, and ensures consistency in product dimensions, sealing performance, and ease of opening.

Easy Maintenance

The equipment is modularly designed, making key components easy to disassemble and replace. Online diagnostics and data monitoring systems provide real-time feedback on equipment status and mold wear, enabling operators to perform maintenance and adjustments quickly, thereby minimizing downtime and ensuring long-term stable operation.

Stable Production Capacity

Easy open-end can lines maintain consistent output even at high production speeds. Precision design of blanking, drawing, and curling processes ensures uniform lid dimensions and reliable tab quality. Stable production capacity meets large-volume manufacturing requirements while ensuring consistent product quality for the market.

Improved Operational Efficiency

Intelligent line control and online monitoring provide real-time production data, supporting process optimization and production management. Multi-specification and multi-material adaptability allow flexible switching between different product types without frequent stoppages, enhancing overall operational efficiency and market responsiveness.

English

English عربى

عربى русский

русский