Tinplate end production refers to the process of using specialized metal packaging machinery to perform stamping, forming, flanging, coating, inspection, and packaging operations on tinplate material, ultimately producing can ends suitable for various types of metal containers. As a critical structural component in metal packaging, can ends directly influence sealing performance and product safety, while also affecting packaging strength, logistics stability, and storage durability.

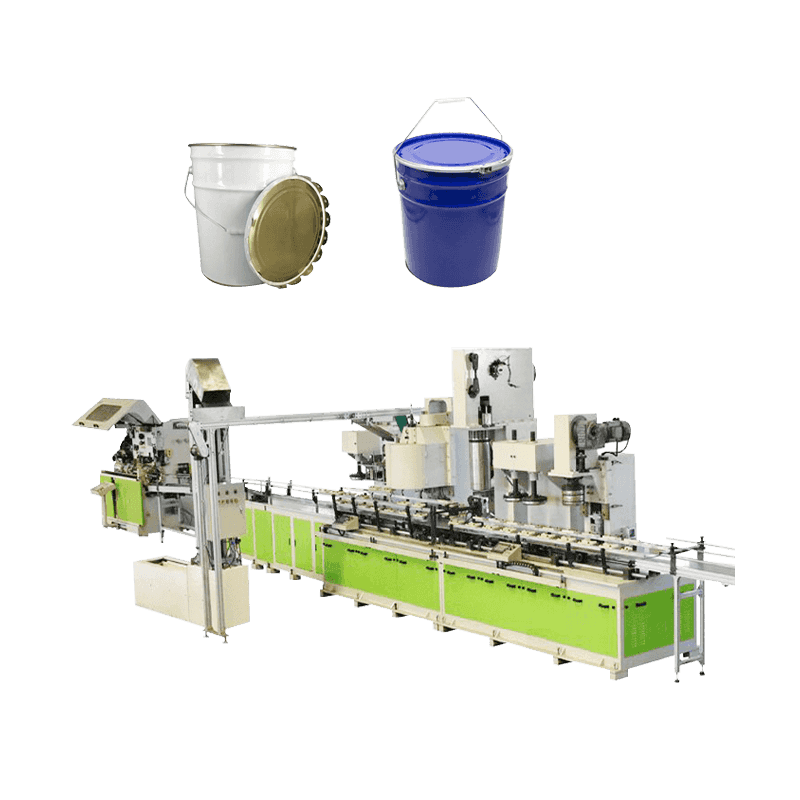

During tinplate end production, high-quality tinplate coils are typically fed into the stamping station through an automatic feeding system. Under the continuous operation of a high-speed press, the can end gradually takes shape through processes such as drawing, flanging, and reinforcing rib formation. To ensure strength and sealing performance, the production line is equipped with specialized curling or flanging machines that form a stable geometric edge. In the production of certain food, beverage, or chemical can ends, additional processes such as coating, adhesive application, or sealing compound forming may be included to enhance corrosion resistance and sealing quality.

Modern tinplate end production emphasizes automation, stability, and consistent quality. Advanced PLC control systems and HMI touch screens allow for convenient parameter adjustment, production monitoring, and rapid fault diagnosis. Automated inspection technologies—such as CCD visual inspection, compound defect detection, and dimensional measurement—can identify defects in real time during production, reducing labor dependence and improving the overall pass rate. For factories with high output requirements, the entire line can operate fully automatically, from coil feeding to can-end packing, significantly improving efficiency and lowering labor costs.

As the packaging industry continues to focus on food safety, environmental protection, and production efficiency, tinplate end production technology is evolving. Innovations such as lower-energy drive systems, more durable tooling materials, smarter inspection algorithms, and modular production line structures make the manufacturing process more efficient and easier to maintain. For customers requiring customized can-end designs, production lines can be tailored based on unique structural specifications, material thicknesses, and production speeds, helping manufacturers achieve multi-variety, high-quality, and stable production capacity.

English

English عربى

عربى русский

русский